Method for preparing soil conditioner by utilizing sediments in plateau lake

A soil conditioner and sediment technology, which is applied in the field of lake sediment reuse, can solve the problems of secondary pollution, difficult problems, and waste of resources in the stacking area, achieve slow release effect, improve nutrient utilization rate, and realize waste utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

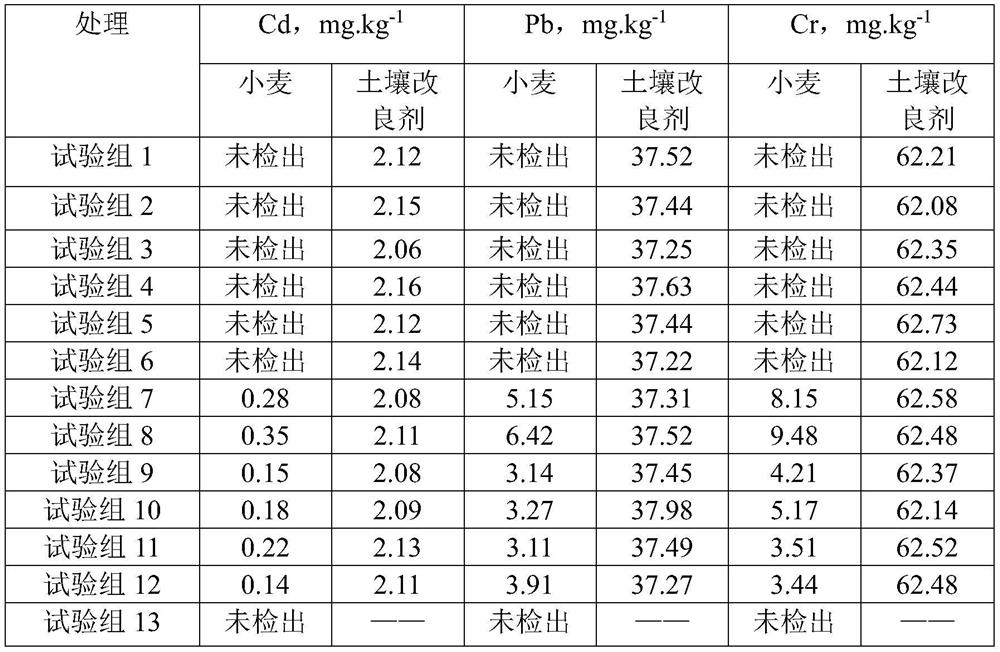

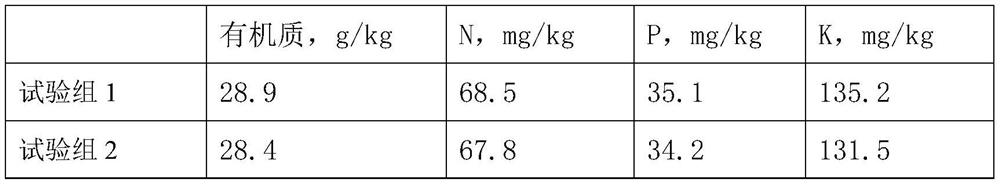

Examples

Embodiment 1

[0027] According to the mass ratio of 10:3:3:2, take plateau lake sediments and straw powder (corn straw is dried to a moisture content of less than 10% and then pulverized through a 100-mesh sieve), livestock manure (pig manure), and activated carbon. In a microwave environment, 1000W, 150 DEG C of microwave treatment for 20min, dehydrated to a moisture content of 50% to obtain a mixture.

[0028] Mixtures and microbial inoculants (20 parts of Bacillus subtilis, 15 parts of Bacillus lateralis, 10 parts of photosynthetic bacteria, 5 parts of nitrifying bacteria, 5 parts of nitrogen-fixing bacteria, 10 parts of total strains 8 cfu / g) are mixed according to the mass ratio of 200:0.5, and then aerobic compost fermentation is carried out to obtain a fermentation product, the fermentation process temperature is 35-45° C., and the fermentation time is 4 days.

[0029] After the fermentation product is freeze-dried in a low temperature vacuum, a heavy metal chelating agent (commercia...

Embodiment 2

[0031] According to the mass ratio of 5:5:8:5, take the plateau lake sediment and straw powder (the corn straw is dried to a moisture content of less than 10% and then pulverized through a 100-mesh sieve), livestock manure (pig manure), and activated carbon. In the microwave environment, 500W, 200 DEG C of microwave treatment for 10min, dehydrated to a moisture content of 75% to obtain a mixture.

[0032] Mixtures and microbial inoculants (10 parts of Bacillus subtilis, 20 parts of Bacillus lateralis, 5 parts of photosynthetic bacteria, 3 parts of nitrifying bacteria, 3 parts of nitrogen-fixing bacteria, the total amount of bacteria is 10 8 cfu / g) are mixed according to a mass ratio of 300:1, and then aerobic compost fermentation is carried out to obtain a fermentation product, the fermentation process temperature is 35-45° C., and the fermentation time is 3 days.

[0033] After the fermentation product is subjected to low temperature vacuum freeze drying, the heavy metal chel...

Embodiment 3

[0035] According to the mass ratio of 10:3:3:2, take plateau lake sediment and straw powder (corn straw is dried to a moisture content of less than 10% and then pulverized through a 100-mesh sieve), livestock manure (pig manure), and activated carbon. In a microwave environment, 1000W, 150 DEG C of microwave treatment for 20min, dehydrated to a moisture content of 50% to obtain a mixture.

[0036] Mixtures and microbial inoculants (20 parts of Bacillus subtilis, 15 parts of Bacillus lateralis, 10 parts of photosynthetic bacteria, 5 parts of nitrifying bacteria, 5 parts of nitrogen-fixing bacteria, 10 parts of total strains 8 cfu / g) are mixed according to the mass ratio of 200:0.5, and then aerobic compost fermentation is carried out to obtain a fermentation product, the fermentation process temperature is 35-45° C., and the fermentation time is 4 days.

[0037] After the fermentation product is freeze-dried in a low temperature vacuum, a heavy metal chelating agent (commercial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com