Method for removing vanadium, manganese and chromium impurities in acid-soluble titanium slag

A technology containing vanadium, manganese, chromium and titanium slag, which is applied in the field of titanium slag smelting, can solve the problems of unfavorable effects of sulfuric acid process titanium dioxide production, low removal rate of impurity elements, etc., and achieve high production capacity, low ferrous content and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

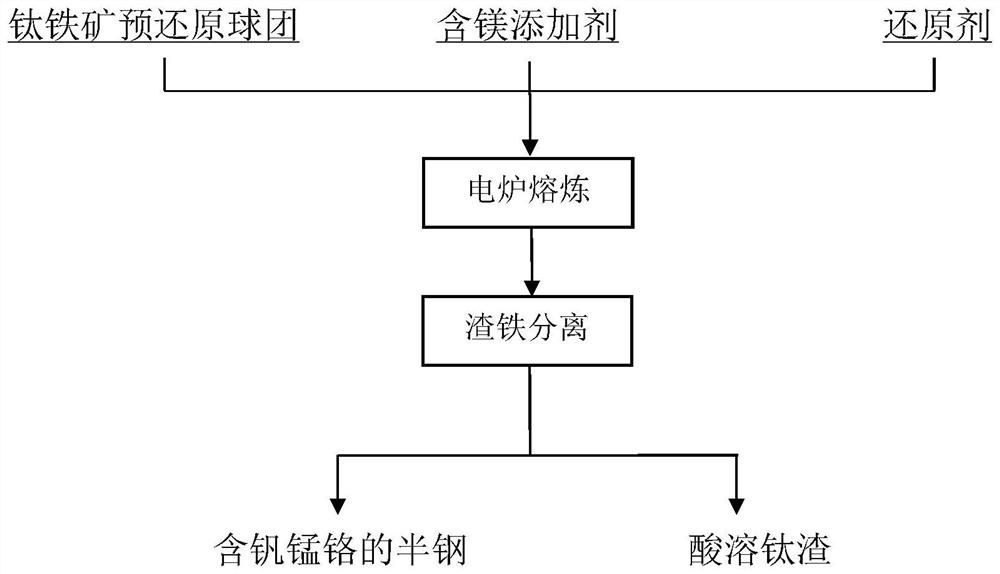

Method used

Image

Examples

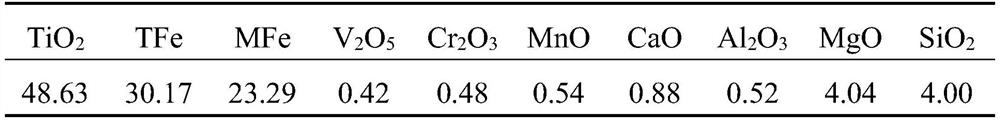

Embodiment 1

[0028] Add ilmenite pre-reduced pellets, magnesium-containing additives and reducing agents into the electric furnace in proportion, add magnesite according to the MgO content in the slag is 10%, and TiO in the slag 2 FeO content ≥ 74wt%, FeO content ≤ 5wt%, smelting temperature 1600°C, smelting time 90min, carbon content 6% (coke), separated to obtain vanadium-manganese-chromium-containing semi-steel and acid-soluble titanium slag, and the obtained vanadium-manganese-chromium-containing iron water is used Vanadium, manganese and chromium were extracted in the converter. After analysis and detection, it was found that 90.47% of the vanadium, 92.08% of the manganese and 85.37% of the chromium in the raw material ilmenite entered the semi-steel, and the TiO-containing 2 It is 76.89% acid-soluble titanium slag, the ferrous content is 4.45%, and the V in the slag 2 o 5 、Cr 2 o 3 , MnO content are 0.04%, 0.038%, 0.079%, respectively, meet the acid-soluble titanium slag standard ...

Embodiment 2

[0030] Add ilmenite pre-reduced pellets, magnesium-containing additives and reducing agents to the electric furnace in proportion, add magnesium oxide according to the MgO content in the slag is 14%, and TiO in the slag 2 Content ≥ 74wt%, FeO content ≤ 5wt%, smelting temperature 1650°C, smelting time 60min, carbon content 7% (coal powder), separated to obtain vanadium-manganese-chromium-containing semi-steel and acid-soluble titanium slag, obtained vanadium-manganese-chromium-containing molten iron It is used to extract vanadium, manganese and chromium in the converter. After analysis and detection, it is found that 90.95% of the vanadium, 92.50% of the manganese and 86.29% of the chromium in the raw material ilmenite enter the semi-steel, and the TiO-containing 2 It is 75.65% acid-soluble titanium slag, the content of ferrous iron is 4.26%, and the V in the slag 2 o 5 、Cr 2 o 3 , MnO content are 0.038%, 0.036%, 0.074%, respectively, meet the acid-soluble titanium slag stan...

Embodiment 3

[0032] Add ilmenite pre-reduced pellets, magnesium-containing additives and reducing agents into the electric furnace in proportion, add magnesite according to the MgO content in the slag is 16%, and TiO in the slag 2 Content ≥ 74wt%, FeO content ≤ 5wt%, smelting temperature 1700°C, smelting time 60min, carbon content 8% (semi-coke), separated to obtain vanadium-manganese-chromium-containing semi-steel and acid-soluble titanium slag, and obtained vanadium-manganese-chromium-containing molten iron It is used to extract vanadium, manganese and chromium in the converter. After analysis and detection, it is found that 92.38% of the vanadium, 93.54% of the manganese and 87.04% of the chromium in the raw material ilmenite enter the semi-steel, and the TiO-containing 2 It is 74.89% acid-soluble titanium slag, ferrous content is 4.05%, V in the slag 2 o5 、Cr 2 o 3 , MnO content are 0.032%, 0.031%, 0.07%, respectively, meet the acid-soluble titanium slag standard (YB / T 5285-2011), is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com