Guiding member, mechanical system comprising such a guiding member, and method for producing such a guiding member

A technology for guiding members and structural steels, applied in mechanical equipment, agricultural machinery and implements, applications, etc., can solve the problems of high local p.V factor, wear, jamming, etc., achieve excellent wear resistance and adaptability, improve performance / The effect of price ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

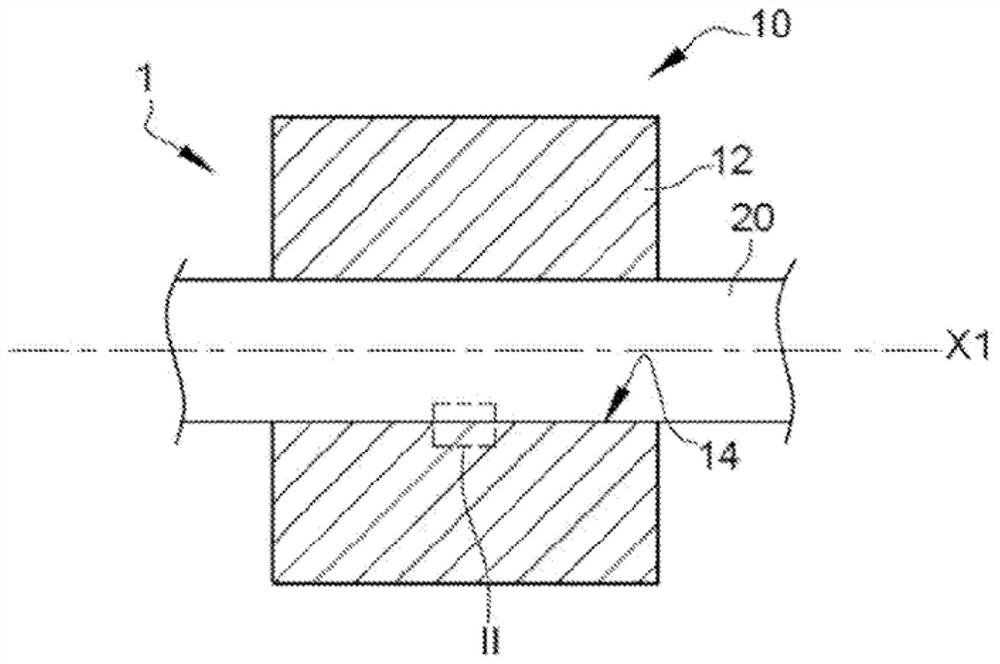

[0029] figure 1 and figure 2 1 shows, comprising the ring 10 and disposed along the longitudinal axis X1 of the present invention the mechanical shaft system of the present invention in ring 10 20.

[0030] The system 1 is designed to withstand high loads and / or impact in the abrasive environment. 1 for example, a joint system for public works or mining machinery, farm vehicles, industrial machinery for the steel industry and the like.

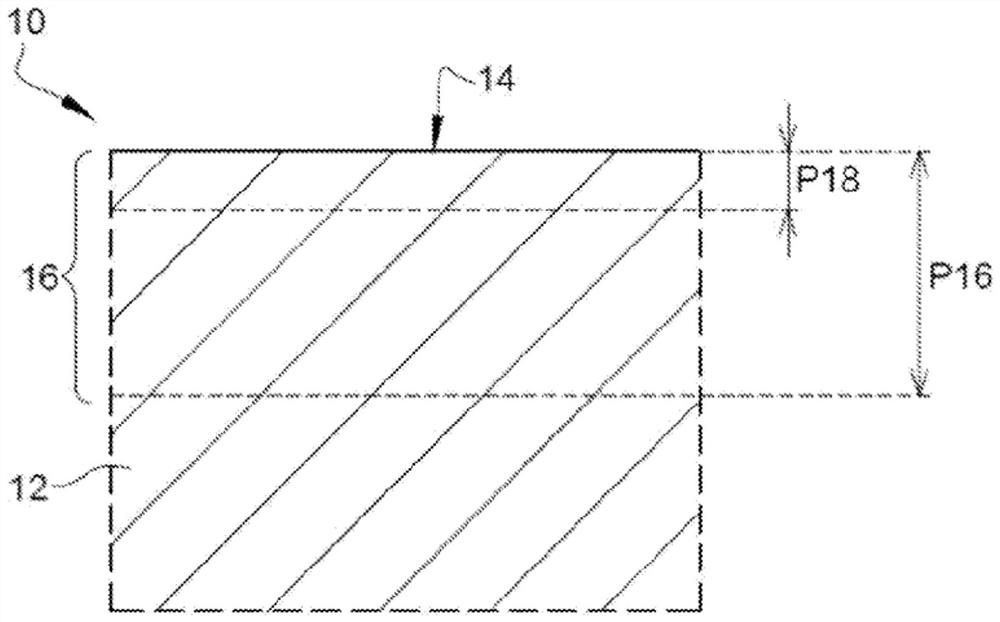

[0031] Ring 10 includes a body 12 having a cylindrical profile and a hole formed in the body 12, 14. Hole 14 is provided to receive the shaft 20, the shaft may be continuous or reciprocating motion in accordance with the rotational movement about the axis X1 and / or translational movement along the axis X1. The guide ring 10 constitute a rotation shaft 20 and the translating member or / .

[0032] Preferably, between the ring 10 and the shaft 20, more specifically, the outer surface of the frictional interface between the hole 14 and the shaft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com