MoS2/organic silicon blended matrix membrane, preparation method and application thereof

A technology of organosilicon and organosilicon sol, which is applied in the field of membrane separation, can solve the problems of bonding to prepare separation membranes, no active groups, no permeability and selective separation membranes, etc., to improve permeation selectivity and promote permeation The effect of passing and increasing the permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention provides a kind of MoS 2 / The preparation method of organosilicon blend matrix film, comprises the following steps:

[0034] Step 1: Preparation of organosilicon sol by hydrolytic polymerization of organoalkoxysilane:

[0035] Mix organoalkoxysilane, water and catalyst in ethanol evenly, wherein the molar ratio of organoalkoxysilane to water and catalyst is 1:10~300:0.1~0.8, and organoalkoxysilane is mixed in organoalkoxysilane , water, catalyst, and ethanol in a mixed solution with a content of 2.0-5.0 wt.%, and after stirring at 20-60° C. for 1-5 hours, the organosilicon sol is obtained.

[0036] Organoalkoxysilanes selected from bis(triethoxysilyl)methane (BTESM), 1,2-bis(triethoxysilyl)ethane (BTESE), 1,3-bis(triethoxy One or more of silyl) propane (BTESP).

[0037] The catalyst contains H + acidic catalyst.

[0038] Step 2: Put MoS 2 Preparation of MoS by uniform mixing of dispersion liquid and organosilica sol 2 / Sil...

Embodiment 1

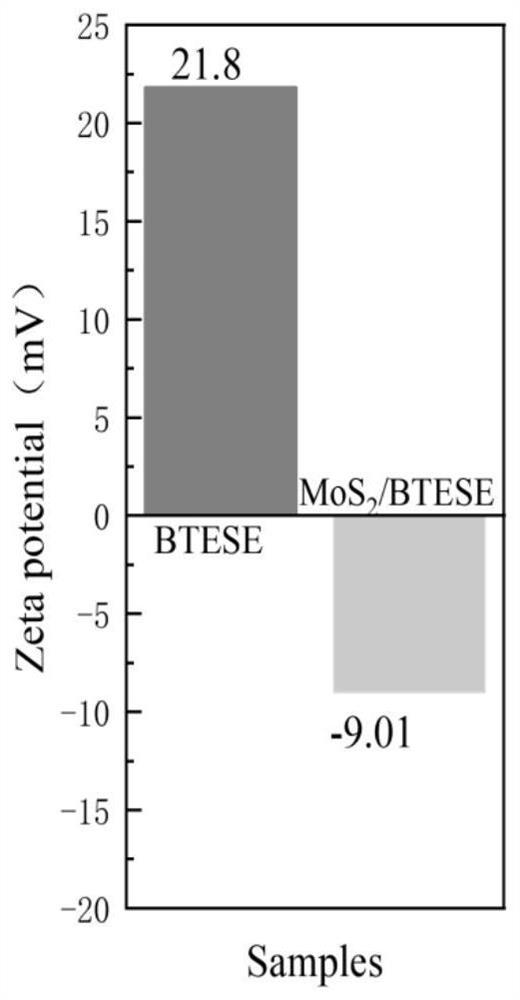

[0052] (1) prepare organosilicon sol, the BTESE of 1.0g is dissolved in the ethanol of 15.9g, then add the water of 3.0g and the massfraction of 0.1g be the HCl of 35wt.%, form uniform 5.0wt.%BTESE solution, Then put it in a 40°C water bath and stir for 5h to prepare the BTESE sol.

[0053] (2) First, 9.5 g of ethanol was added to 9.5 g of water to form a 50% ethanol / water mixture with a total mass of 19.0 g. 1.0g of MoS 2 Added to the above solution by ultrasonic dispersion to form 5.0 wt.% MoS 2 solution. Then take 1.0 g of 5.0 wt% MoS 2 Solution, then add 2.0g of 5.0wt.% BTESE sol in step (1), and finally add 7.0g of ethanol and ultrasonic 30min to obtain MoS 2 / BTESE dispersion. in MoS 2 / BTESE dispersion, MoS 2 The content of BTESE is 0.5wt.%, the content of BTESE is 1.0wt.%.

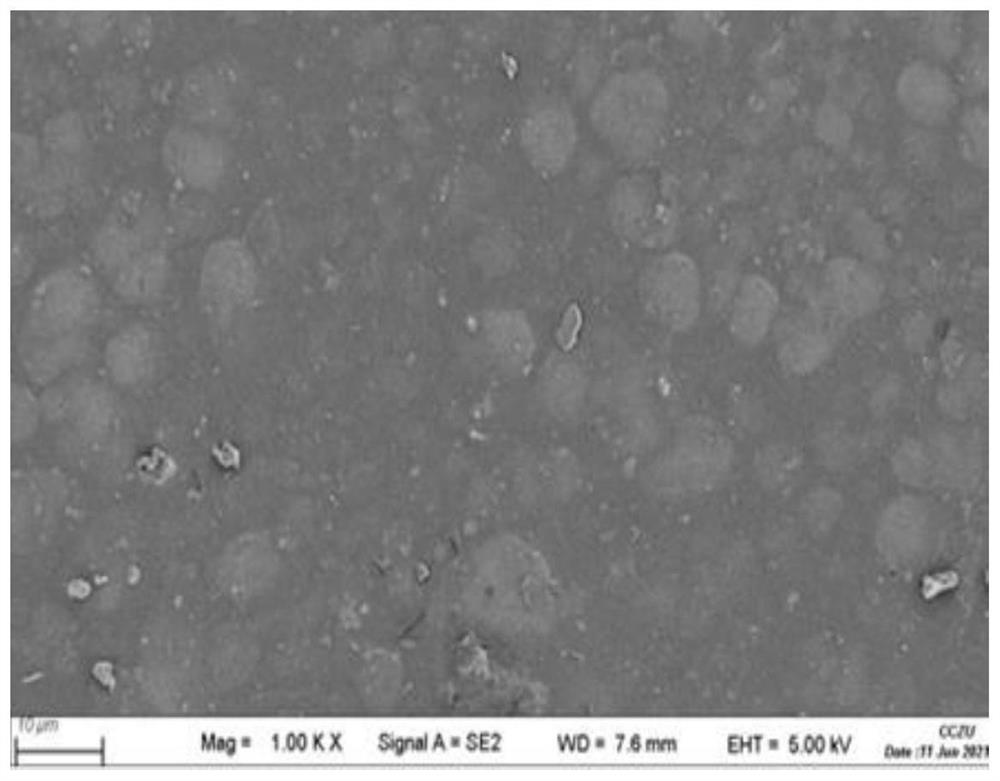

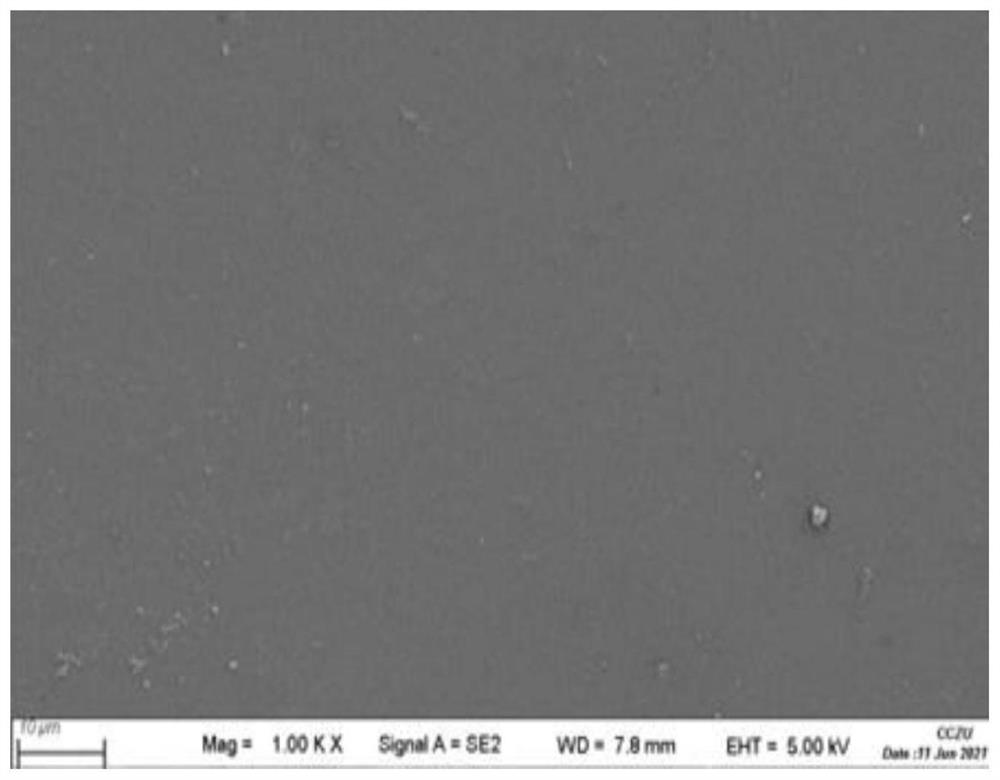

[0054] (3) Preparation of the support body: use the wiping method to coat the sheet ceramic carrier with SiO 2 -ZrO 2 Sol modification, drying at room temperature for five minutes after r...

Embodiment 2

[0060] (1) prepare organosilicon sol, the BTESE of 1.0g is dissolved in the ethanol of 15.9g, then add the water of 3.0g and the massfraction of 0.1g be the HCl of 35wt.%, form uniform 5.0wt.%BTESE solution, Then put it in a 40°C water bath and stir for 5h to prepare the BTESE sol.

[0061] (2) First, 9.5 g of ethanol was added to 9.5 g of water to form a 50% ethanol / water mixture with a total mass of 19.0 g. 1.0g of MoS 2 Added to the above solution by ultrasonic dispersion to form 5.0 wt.% MoS 2 solution. Then take 1.0g of 5.0wt.% MoS 2 Solution, then add 1.0g of 5.0wt.% BTESE sol in step (1), and finally add 3.0g of ethanol and ultrasonic for 30min to obtain MoS 2 / BTESE dispersion. in MoS 2 / BTESE dispersion, MoS 2 The content of BTESE is 1.0wt.%, and the content of BTESE is 1.0wt.%.

[0062] (3) Preparation of the support body: use the wiping method to coat the sheet ceramic carrier with SiO 2 -ZrO 2 Sol modification, drying at room temperature for five minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com