Preparation of iron-based biochar wave-absorbing material and method for repairing mercury-polluted soil through synergy of iron-based biochar wave-absorbing material and microwaves

A biochar, mercury pollution technology, applied in the field of soil remediation, can solve the problems of high soil mercury content, incomplete remediation, high energy consumption, etc., and achieves the effects of high treatment efficiency, suitable for popularization and use, and low implementation temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Grind the shell biochar through a 60-mesh sieve, soak it in 1mol / L phosphoric acid, stir it for 24 hours, wash it with distilled water until neutral, and dry it.

[0026] 2. For the biochar dried in the previous step, mix it with FeCl at a mass ratio of 1:3 3 The solutions were mixed, hydrothermally reacted at 180°C for 12 hours, and washed with distilled water several times after cooling to obtain iron-based biochar.

[0027] 3. Take mercury-contaminated soil (mercury content is 26.875mg / kg) around a mine, remove debris such as grass roots and gravel, air-dry and grind it and pass it through a 60-mesh sieve;

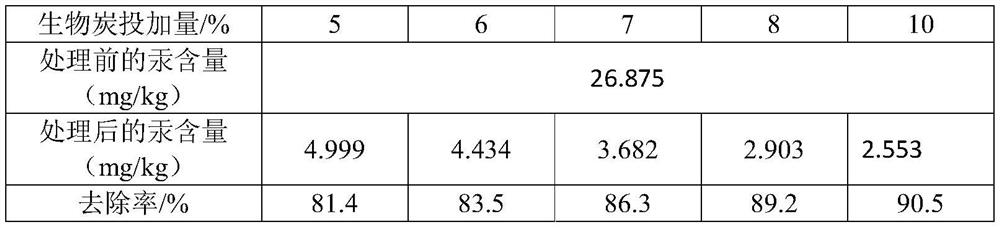

[0028] 4. Weigh 5 parts of the pretreated soil, 100g each, add 5, 6, 7, 8, 10g of iron-loaded biochar respectively, shake and mix for 5min, then put it into the microwave reactor, set the reaction temperature to 200℃, time The reaction time was 60min and the microwave heating power was 600w.

[0029] After the reaction, first add aqua regia (acid mixed with ...

Embodiment 2

[0034] 1. Grind the shell biochar through a 60-mesh sieve, soak it in 1mol / L phosphoric acid, stir it for 24 hours, wash it with distilled water until neutral, and dry it.

[0035] 2. For the biochar dried in the previous step, mix it with FeCl at a mass ratio of 1:3 3 The solutions were mixed, hydrothermally reacted at 180°C for 12 hours, and washed with distilled water several times after cooling to obtain iron-based biochar.

[0036] 3. Take mercury-contaminated soil (mercury content is 26.875mg / kg) around a mine, and remove debris such as grass roots and gravel. Air-dried and ground and passed through a 60-mesh sieve;

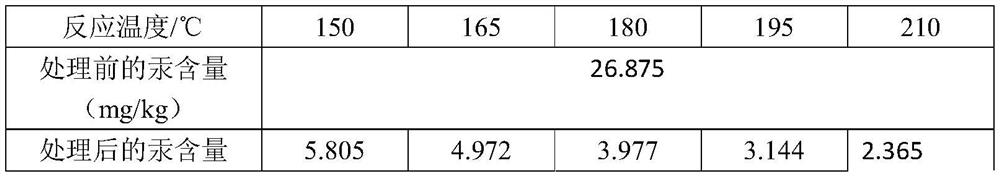

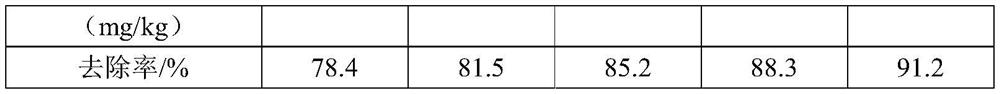

[0037] 4. Weigh 5 parts of the pretreated soil, 100g each, add 8g of iron-loaded biochar respectively, shake and mix for 5min, put them into the microwave reactor, and set the reaction temperature to 150°C, 165°C, 180°C, 195°C respectively , 210°C, the time is 60min, and the microwave heating power is 600w to carry out the reaction.

[0038] After the re...

Embodiment 3

[0044] 1. Grind the shell biochar through a 100-mesh sieve, soak it in 3mol / L phosphoric acid, stir it for 12 hours, wash it with distilled water until neutral, and dry it.

[0045] 2. For the biochar dried in the previous step, mix it with FeSO at a mass ratio of 1:6 4 The solutions were mixed, hydrothermally reacted at 200°C for 8 hours, and washed with distilled water several times after cooling to obtain iron-based biochar.

[0046] 3. Take mercury-contaminated soil (mercury content is 145.475mg / kg) around a mine, remove debris such as grass roots and gravel, air-dry and grind it and pass it through a 100-mesh sieve;

[0047] 4. Weigh 5 parts of the pretreated soil, 100g each, add 8g of iron-loaded biochar, shake and mix for 5 minutes, then put it into the microwave reactor, set the reaction temperature to 200°C, and set the time to 60min, 80min, and 100min respectively , 120min, and the microwave heating power was set to 600w for reaction.

[0048] After the reaction, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com