System and method for preventing powder conveying pipeline from being blocked

A powder conveying and conveying pipeline technology, applied in the field of powder conveying and maintenance, can solve problems such as blockage of powder conveying pipeline system, and achieve the effect of reducing the frequency of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

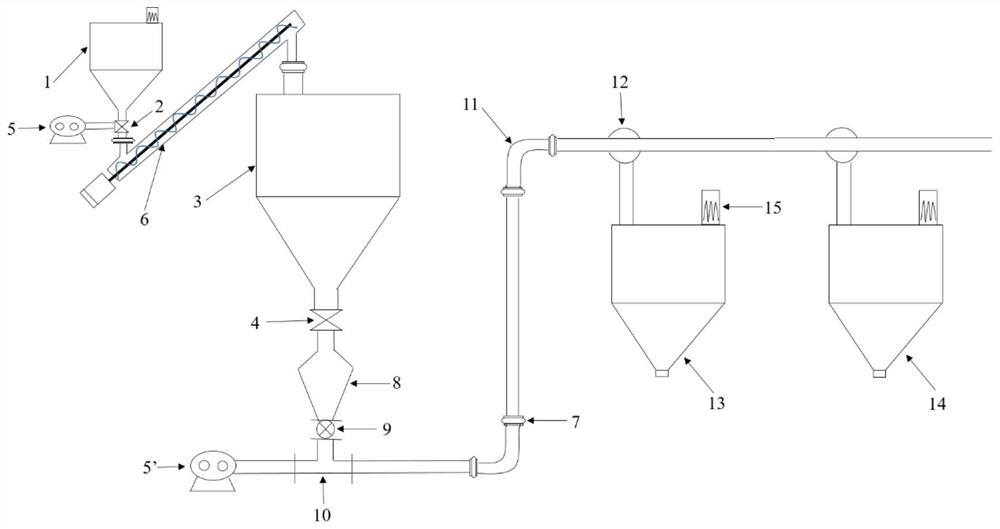

[0065] Such as figure 1 As shown, the powdered antistatic agent stearylamine polyoxyethylene ether and the powder to be transported are metered and added to the mixing chamber through the rotary valves (not shown) of the respective silos (not shown). In the silo 1, wherein, the addition amount of stearylamine polyoxyethylene ether is 5wt% of the addition amount of the powder to be conveyed, and the air flow mixes the first fan 5 continuously to the mixing silo 1 through the conveying pipeline and the mixing silo valve 2 Conveying gas for airflow mixing, wherein the gas delivered by the first fan 5 to the mixing silo 1 is high-pressure nitrogen. During the airflow mixing process, the powder in the mixing silo 1 is in a boiling state. After mixing for 30 minutes, an antistatic agent is obtained. Evenly dispersed mixed material, the mixed material is transported to the storage bin 3 through the screw 6, and the nitrogen gas delivered by the first fan 5 is mixed with the air flow ...

Embodiment 2

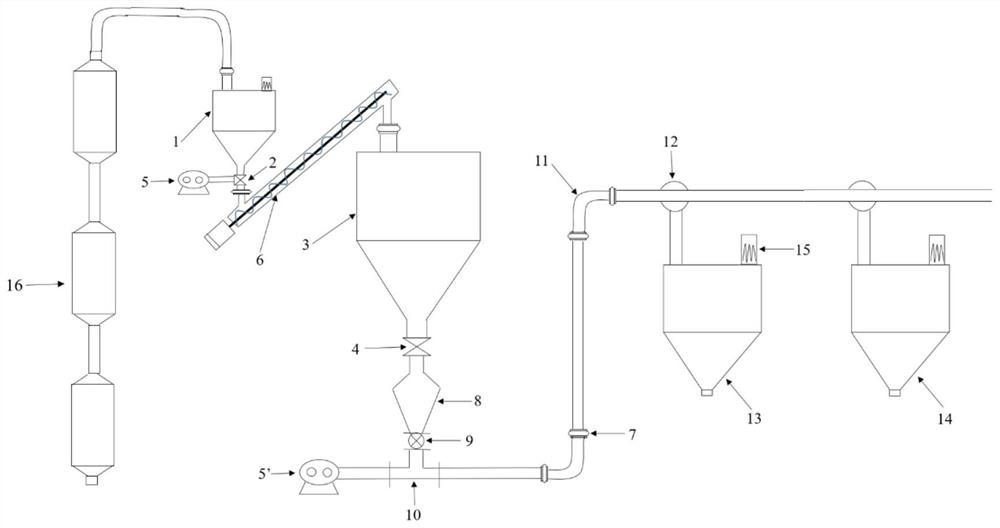

[0067] Such as figure 2 As shown, powdered antistatic agent sodium dodecylbenzene sulfonate and solvent-containing ultra-high molecular weight polyethylene wet powder are metered into the airflow dryer 16 respectively, wherein the antistatic agent dodecylbenzene The sodium sulfonate addition is 2wt% of the addition of solvent-containing ultra-high molecular weight polyethylene wet powder (the powder amount here is calculated by the product of solvent-containing ultra-high molecular weight polyethylene wet powder amount and wet powder solid content) . The mixture of the two was mixed and dried in an airflow dryer 16 at 60° C. for 2 hours to completely remove the solvent in the UHMWPE wet powder. After cooling down to room temperature, the mixture powder is transported to the mixing bin 1 by high-pressure gas through the pipeline, and then, the same steps as in Example 1 are used to carry out the powder transport, and finally the powder added with the antistatic agent is trans...

Embodiment 3

[0069] The powdered antistatic agent pentaerythritol tetrastearate is metered into the slurry storage tank (not shown in the figure) of the ultra-high molecular weight polyethylene slurry or suspension after polymerization, wherein the antistatic agent pentaerythritol tetrastearate The addition of stearate is the 3.5wt% of ultra-high molecular weight polyethylene powder amount (the ultra-high molecular weight polyethylene powder amount here, by ultra-high molecular weight polyethylene slurry amount and ultra-high molecular weight polyethylene slurry solid content Calculated by the product of), the two were mechanically stirred in the slurry storage tank for 30 minutes, so that the antistatic agent pentaerythritol tetrastearate and the polymerized ultra-high molecular weight polyethylene slurry or suspension were fully mixed to obtain antistatic A mixture slurry in which the antistatic agent is uniformly dispersed, and the solvent in the mixture slurry is separated through a sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com