Preparation method of molybdenum disulfide nanosheet

A technology of molybdenum disulfide and nanosheets, which is applied in the field of preparation of molybdenum disulfide nanosheets, can solve cumbersome and complicated problems, achieve the effects of low equipment requirements, simple preparation methods, and save time and scientific research costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

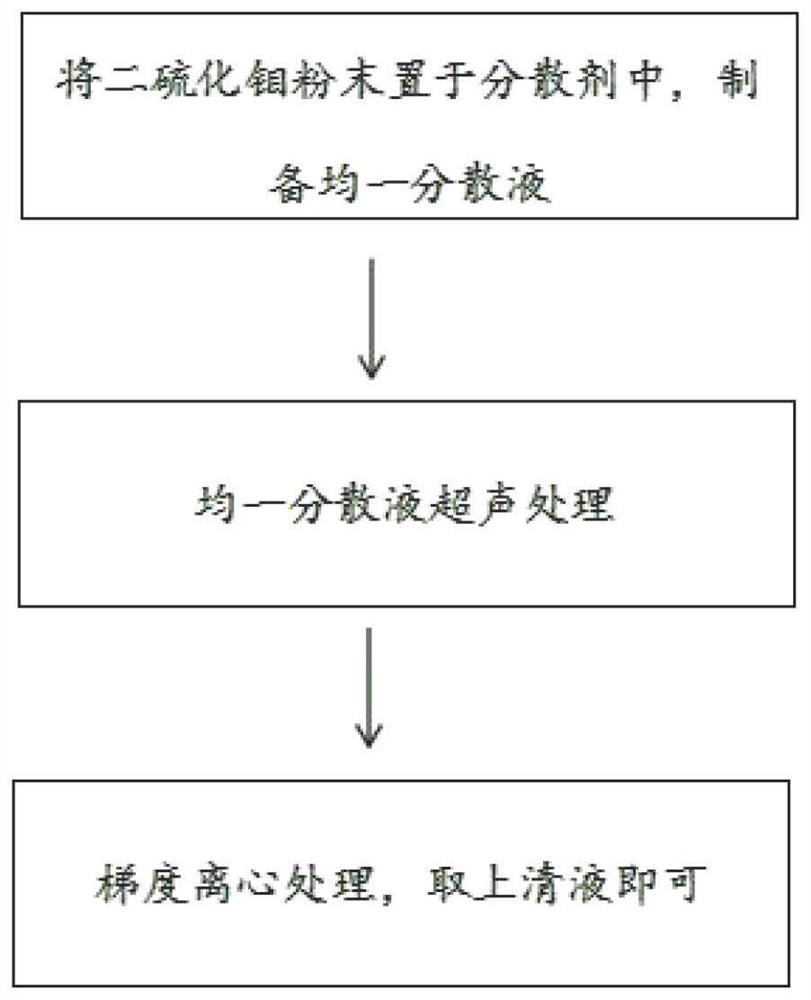

[0024] A preparation method of molybdenum disulfide nanosheets, such as figure 1 shown, including the following steps:

[0025] (1) First weigh 0.1g molybdenum disulfide powder, then measure 60mL of DMF and 20mL of H 2 O and mix the two;

[0026] (2) Mix the DMF and H 2 O mixture was put into a magnetic stirrer and stirred for 30 minutes, then molybdenum disulfide powder was added, and stirring was continued for 10 minutes to prepare a uniform dispersion;

[0027] (3) Pour the stirred homogeneous dispersion into a beaker and cover the mouth of the bottle with plastic wrap, and then perform ultrasonic treatment, the ultrasonic power is 100W, and the ultrasonic time is 7h;

[0028] (4) Use a burette to transfer the mixed solution after ultrasonication to a centrifuge tube, and use gradient centrifugation to centrifuge the mixed solution at 2000r / min for 20min, then take it out and continue to centrifuge at 5000r / min for 10min, and finally take out the supernatant solution to...

Embodiment 2

[0030] A preparation method of molybdenum disulfide nanosheets, such as figure 1 shown, including the following steps:

[0031] (1) First weigh 0.15g of molybdenum disulfide powder, then measure 80mL of NMP and 20mL of H 2 O and mix the two;

[0032] (2) The mixed NMP and H 2 O mixture was put into a magnetic stirrer and stirred for 20min, then molybdenum disulfide powder was added, and stirring was continued for 20min to prepare a uniform dispersion;

[0033] (3) Pour the stirred homogeneous dispersion into a beaker and cover the mouth of the bottle with plastic wrap, then perform ultrasonic treatment, the ultrasonic power is 200W, and the ultrasonic time is 10h;

[0034] (4) Use a burette to transfer the mixed solution after ultrasonication to a centrifuge tube, and use gradient centrifugation to centrifuge the mixed solution at 2500r / min for 30min, then take it out and continue to centrifuge at 5500r / min for 20min, and finally take out the supernatant solution to obtain...

Embodiment 3

[0036] A preparation method of molybdenum disulfide nanosheets, such as figure 1 shown, including the following steps:

[0037] (1) First weigh 0.35g of molybdenum disulfide powder, then measure 60mL of isopropanol and 20mL of H 2 O and mix the two;

[0038] (2) Mixed isopropanol and H 2 O mixture was put into a magnetic stirrer and stirred for 30 minutes, then molybdenum disulfide powder was added, and stirring was continued for 10 minutes to prepare a uniform dispersion;

[0039] (3) Pour the stirred homogeneous dispersion into a beaker and cover the mouth of the bottle with plastic wrap, then perform ultrasonic treatment, the ultrasonic power is 300W, and the ultrasonic time is 8h;

[0040] (4) Use a burette to transfer the mixed solution after ultrasonication to a centrifuge tube, and use gradient centrifugation to centrifuge the mixed solution at 3000r / min for 25min, then take it out and continue to centrifuge at 6000r / min for 20min, and finally take out the supernatan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com