Novel high-lubrication aluminothermy rough rolling emulsion and preparation method thereof

An emulsion, thermite technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve problems such as uneconomical, unreasonable, and increased desorption tendency of polar molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

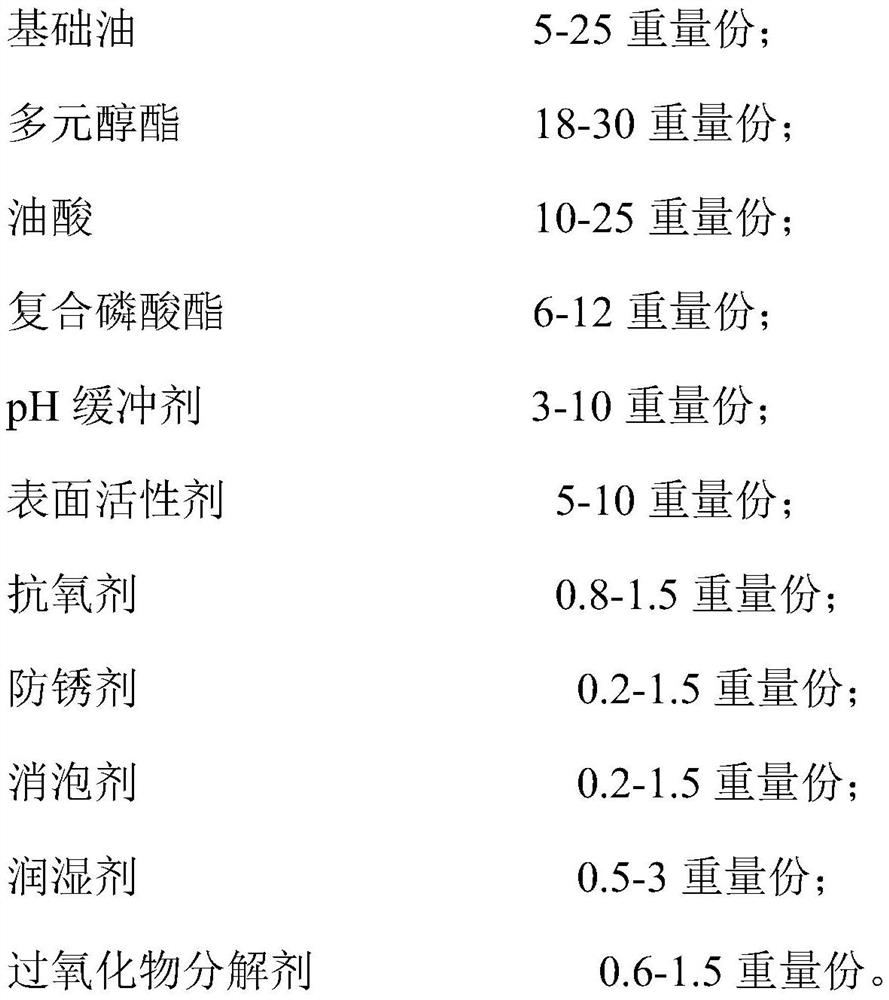

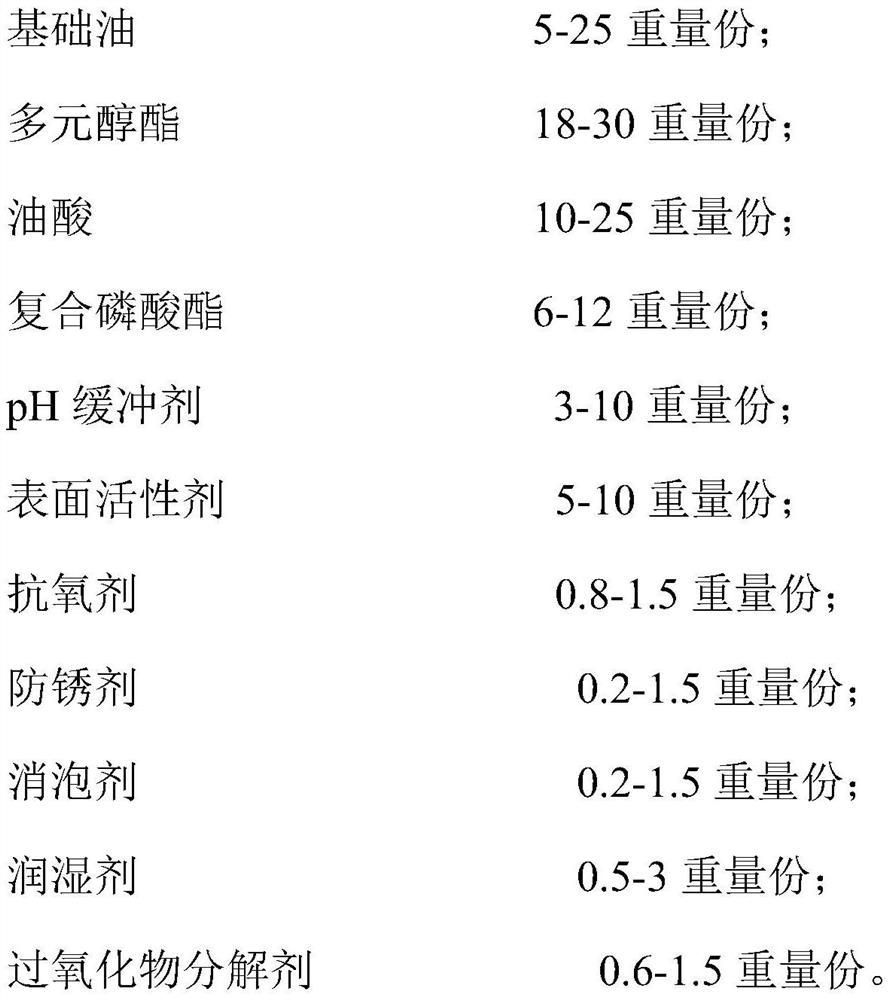

[0035] In the following examples of the present invention, the raw materials are selected according to the proportioning described in the following table 1 respectively, and the specific preparation methods include:

[0036] (1) In the first reactor, add the selected amount of oleic acid, antioxidant, peroxide decomposing agent, antirust agent, heat up to 65°C, stir for 40min, mix until completely dissolved, wait to cool down to Below 50°C, the semi-finished product of the oleic acid mixture is obtained, which is stored for later use;

[0037] (2) add part of naphthenic base oil in the second reaction kettle, heat to 55 ℃, stir for at least 30min; then add the said surfactant of selected amount, polyol ester, wetting agent, complex phosphate, Control the temperature at 55°C, stir for 40 minutes, and mix well;

[0038] (3) Continue to add the oleic acid mixture, defoamer, and pH buffer prepared in step (1) to the above-mentioned second reaction kettle, keep the temperature at ...

experiment example

[0072] The properties of the emulsions described in the above examples and comparative examples were tested respectively, and the test results are shown in Table 2 below. in,

[0073] pH value (5wt% concentration) test: test according to GB / T 9724-2007;

[0074] Emulsion (5wt% concentration) stability index ESI test method: 400ml emulsion with 5wt% concentration was placed in a separatory funnel for 4 hours, the lower layer and upper layer 45ml emulsion were respectively removed, strong acid and deionized water were added to separate oil and water, and the oil was measured. Phase volume, the ratio of the measured lower emulsion oil phase to the upper emulsion oil phase volume is the emulsion stability index ESI;

[0075] UA value determination method: use the infrared spectrometer to establish a quantitative analysis standard curve, scan the spectrum of the oil sample to be tested, and perform quantitative analysis;

[0076] Hydrophobic viscosity test method: use strong acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com