Intelligent detection modeling method for blanking quality of alloy plate

An alloy sheet, intelligent detection technology, used in instruments, manufacturing computing systems, data processing applications, etc., can solve problems such as wear, sheet burrs, cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Intelligent detection modeling method for impact quality of Q235 low carbon steel alloy sheet based on acoustic emission technology, including the following steps:

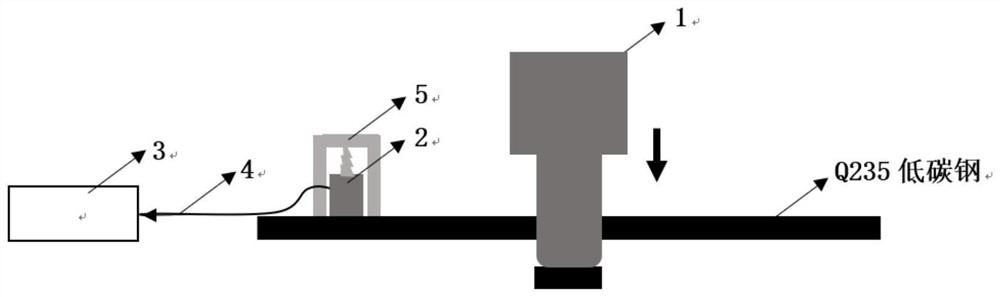

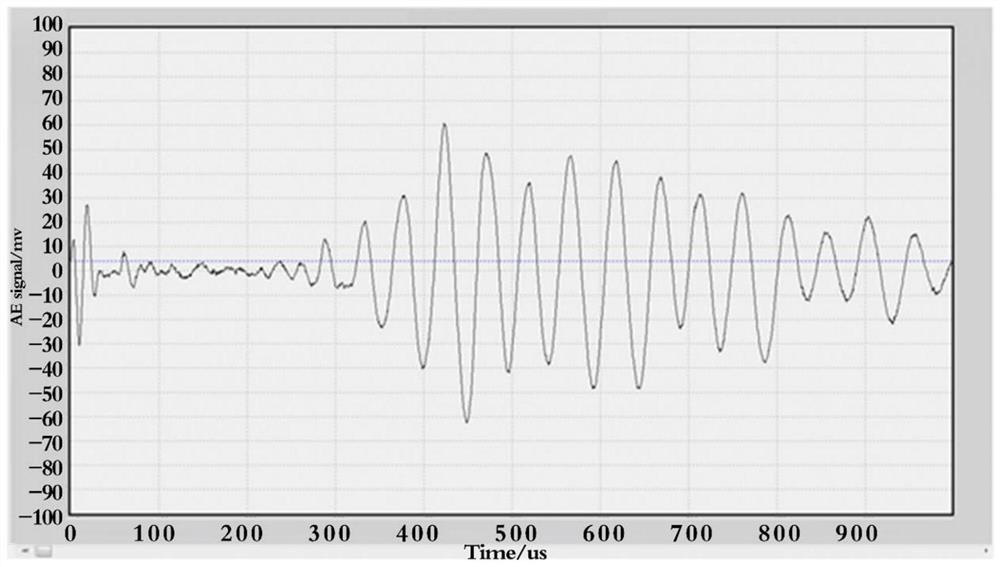

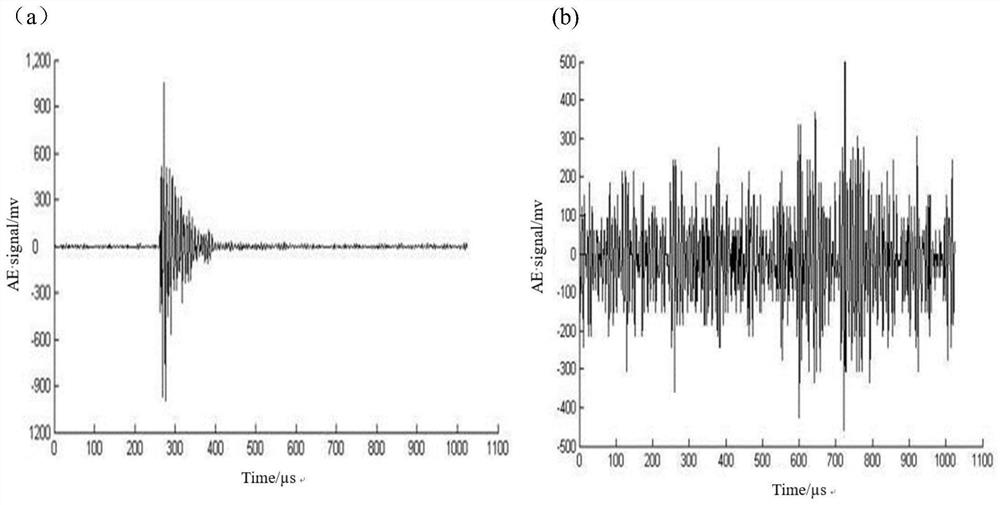

[0065] S1, inspection sound transmission sensor coupling before the punching experiment, and set the threshold to remove noise. The experimental device includes a punching machine 1, an acoustic transmitting sensor 2, a signal collector 3, a connecting line 4, a clamp 5, and a device schematic figure 1 Indicated. During the experiment, the acoustic emission sensor 2 is fixed to the position of the Q235 low carbon steel sheet, and the sound emission sensor and the sheet are applied to the Vaseline coupling agent. After fixing, the sensitivity of the sensor and the coupling between the sensor and the sheet material is obtained at the position of the distance sensor and the coupling between the sensor and the sheet material, and the obtained waveform signal is a burst signal. figure 2 The time-acoustic signal ampl...

Embodiment 2

[0108] Intelligent detection modeling method of 6082 aluminum alloy plate based on acoustic emission technology, including the following steps:

[0109] S1, inspection sound transmission sensor coupling before the punching experiment, and set the threshold to remove noise. The experimental device includes a punching machine 1, an acoustic transmitting sensor 2, a signal collector 3, a connecting line 4, a clamp 5, and a device schematic Image 6 Indicated. During the experiment, the acoustic emission sensor is secured to the plate material on the plate, and a Vaseline coupling agent is applied between the edge of the dies-by 10 mm. After fixing, the sensitivity of the sensor and the coupling between the sensor and the sheet material is obtained at the position of the distance sensor and the coupling between the sensor and the sheet material, and the obtained waveform signal is a burst signal. Figure 7 The time-acoustic signal amplitude is shown in the fuel-lead experiment. Open the...

Embodiment 3

[0151] AZ31 magnesium alloy sheet milling quality intelligent detection modeling method based on acoustic emission technology, including the following steps:

[0152] S1, inspection sound transmission sensor coupling before the punching experiment, and set the threshold to remove noise. The experimental device includes a punching machine 1, an acoustic transmitting sensor 2, a signal collector 3, a connecting line 4, a clamp 5, and a device schematic Figure 10 Indicated. During the experiment, the acoustic emission sensor is secured to the sheet of 10 mm from the edge of the punching portion, and the Vaseline coupling agent is applied between the edge of the died portion edge. After fixed, the sensitivity of the sensor and the coupling between the sensor and the sheet material are passed at the position of the distance sensor and the coupling between the sensor and the sheet material, and the coupling degree is good. Open the punching, first collect the sound transmit signal issue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com