Distributed type fiber optic sensor based on optical fiber cavity attenuation and vibration technique

A distributed optical fiber and optical fiber splitter technology, which is applied in the direction of using optical devices to transmit sensing components, optical waveguide coupling, etc., can solve problems such as processing difficulties, limiting the range of laser wavelengths, and inability to meet distributed sensing requirements. , to achieve the effect of high measurement accuracy, fast measurement speed and easy expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described now in conjunction with accompanying drawing:

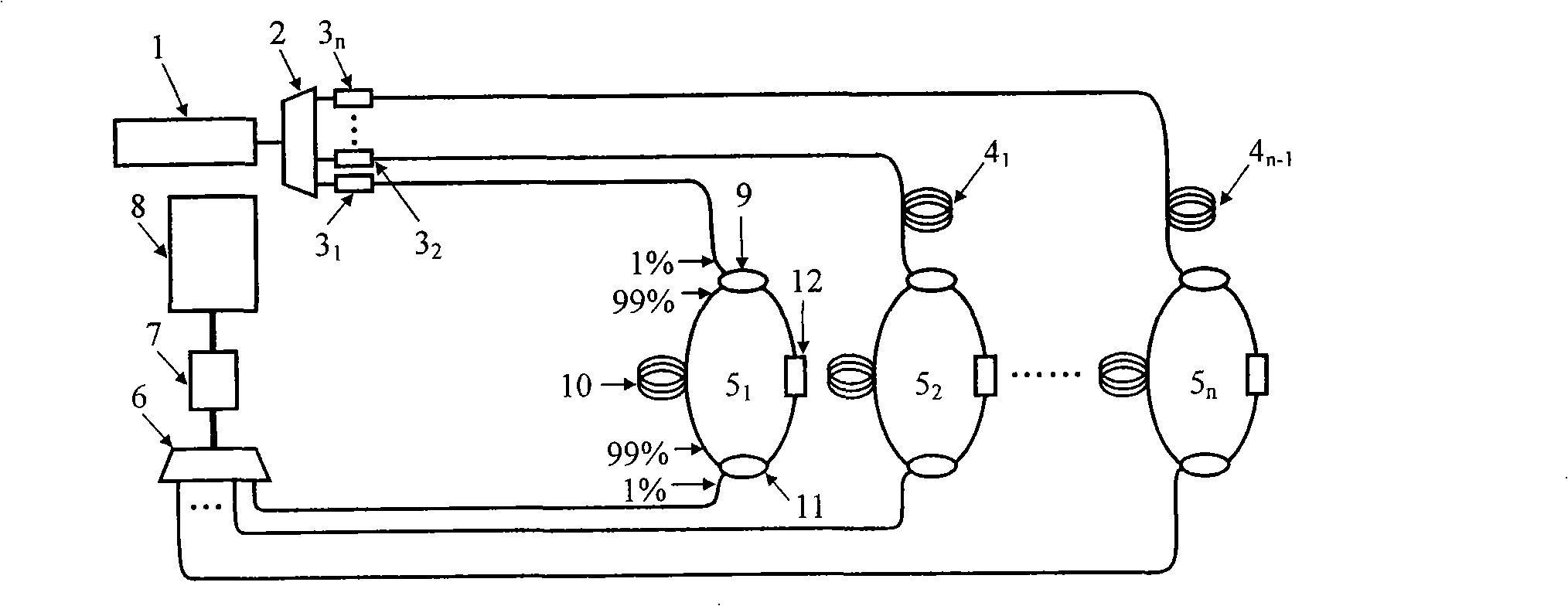

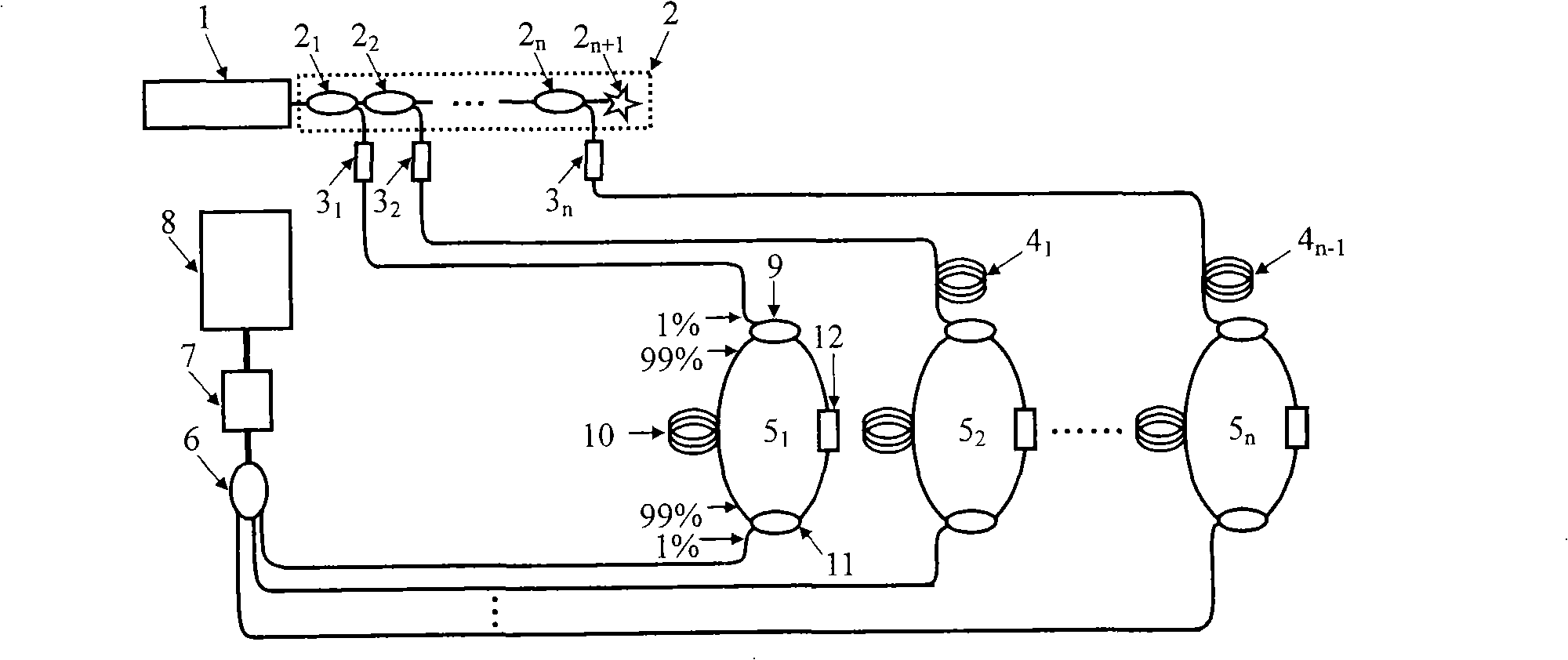

[0027] Device embodiment 1, such as figure 1 As shown, the present embodiment takes n=4, and the measuring device of the present invention includes: a pulsed laser light source 1, an optical fiber splitter 2, and an adjustable optical attenuator 3 1 、3 2 、3 3 、3 4 , fiber optic delay line 4 1 、4 2 、4 3 , Fiber Ring 5 1 、5 2 、5 3 、5 4 , fiber combiner 6, high-speed photodetector 7, high-speed A / D conversion and signal processing module 8. Fiber ring 5 1 It includes two 1×2 optical fiber couplers 9 and 11 with a splitting ratio of 99%:1%, a single-mode optical fiber 10 and an optical fiber sensing element 12 . The two ends of the single-mode optical fiber 10 are respectively fused with 99% of the two ports of the two optical fiber couplers 9 and 11, and the optical fiber sensing element 12 is respectively connected to the two ports of the two optical fiber couplers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com