Clausena lansium leaf tea with function of clearing damp and production process thereof

A production process, the technology of yellow bark leaves, applied in the field of tea preparation, can solve the problems of little dehumidification effect, poor stability, and short shelf life, and achieve the effect of preventing particle aggregation, good stability, and improving affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

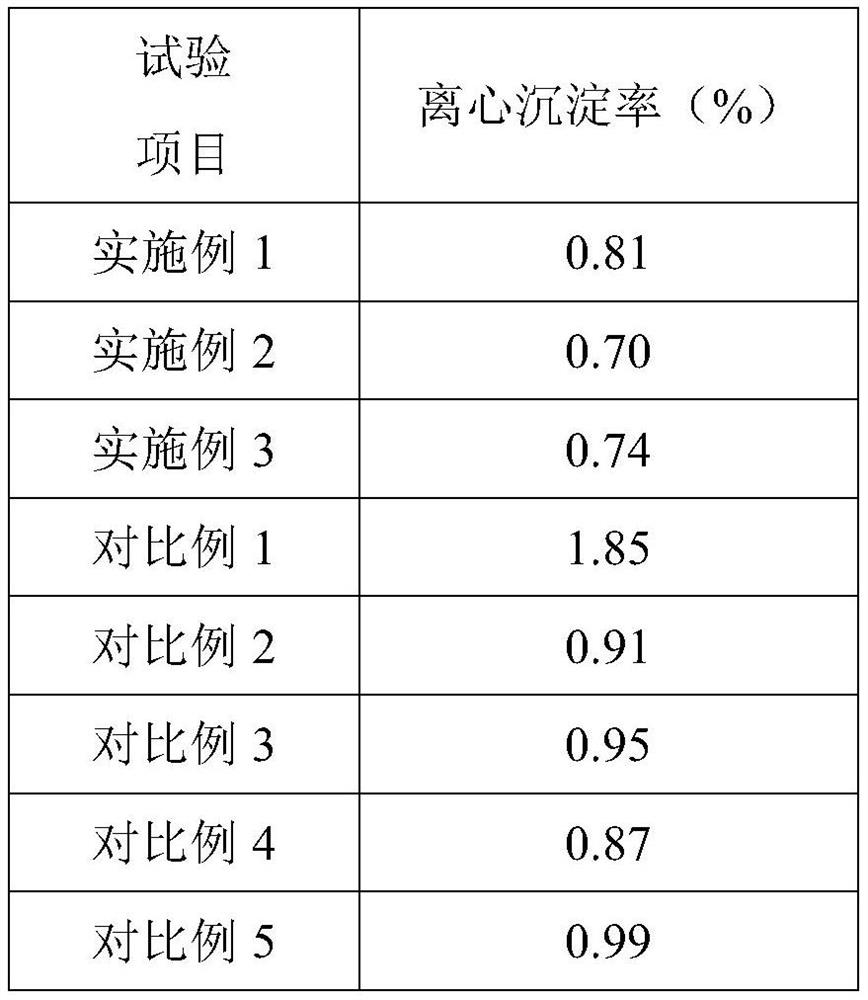

Examples

Embodiment 1

[0044] A yellow skin leaf tea with the function of removing dampness, which comprises the following raw materials in parts by weight: 246 parts of yellow skin leaves, 19 parts of golden clematis, 31 parts of spinach, 20 parts of Chinese toon leaves, 30 parts of dragon fruit, and 1000 parts of water 2 parts of vitamin A, 8 parts of tea polyphenols, 3 parts of apple cider vinegar, 5 parts of D-galactose, 0.4 parts of diacetyl tartrate mono-diglycerides, 0.3 parts of soybean gum, 0.2 parts of sodium citrate;

[0045] The production process of the described yellow bark leaf tea with damp-removing function, comprises the following steps:

[0046] S1: Weighing the leaves of yellow skin, golden clematis, spinach, Chinese toon leaves, and dragon fruit according to the weight ratio, and then mixing the raw materials to obtain the mixed raw materials;

[0047] S2: Put the raw materials mixed in step S1 into water with a temperature of 85° C. for blanching for 2 minutes, then take them o...

Embodiment 2

[0056] A yellow skin leaf tea with the function of removing dampness, which includes the following raw materials in parts by weight: 300 parts of yellow skin leaves, 24 parts of golden clematis, 35 parts of spinach, 28 parts of Chinese toon leaves, 34 parts of dragon fruit, and 1200 parts of water 3 parts of vitamin A, 10 parts of tea polyphenols, 4 parts of apple cider vinegar, 6 parts of D-galactose, 0.5 parts of diacetyl tartrate mono-diglycerides, 0.4 parts of soybean gum, 0.3 parts of sodium citrate;

[0057] The production process of the described yellow bark leaf tea with damp-removing function, comprises the following steps:

[0058] S1: Weighing the leaves of yellow skin, golden clematis, spinach, Chinese toon leaves, and dragon fruit according to the weight ratio, and then mixing the raw materials to obtain the mixed raw materials;

[0059] S2: Put the raw materials mixed in step S1 into water with a temperature of 88°C for blanching for 2 minutes, then take them out...

Embodiment 3

[0068] A yellow skin leaf tea with the function of removing dampness, which includes the following raw materials in parts by weight: 317 parts of yellow skin leaves, 26 parts of golden clematis, 40 parts of spinach, 33 parts of Chinese toon leaves, 39 parts of dragon fruit, and 1400 parts of water 3 parts of vitamin A, 11 parts of tea polyphenols, 5 parts of apple cider vinegar, 8 parts of D-galactose, 0.6 parts of diacetyl tartrate mono-diglycerides, 0.5 parts of soybean gum, 0.4 parts of sodium citrate;

[0069] The production process of the described yellow bark leaf tea with damp-removing function, comprises the following steps:

[0070] S1: Weighing the leaves of yellow skin, golden clematis, spinach, Chinese toon leaves, and dragon fruit according to the weight ratio, and then mixing the raw materials to obtain the mixed raw materials;

[0071] S2: Put the raw materials mixed in step S1 into water with a temperature of 91° C. for blanching for 1 min, then take them out a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com