Automatic medicinal glass bottle boxing machine and system based on sensing intelligent control

A medical glass bottle and automatic cartoning machine technology, which is applied in packaging, packaging bottles, transportation and packaging, etc., can solve the problems of unevenness and collision of medicine bottles, and achieve neat arrangement and smooth boxing process , the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

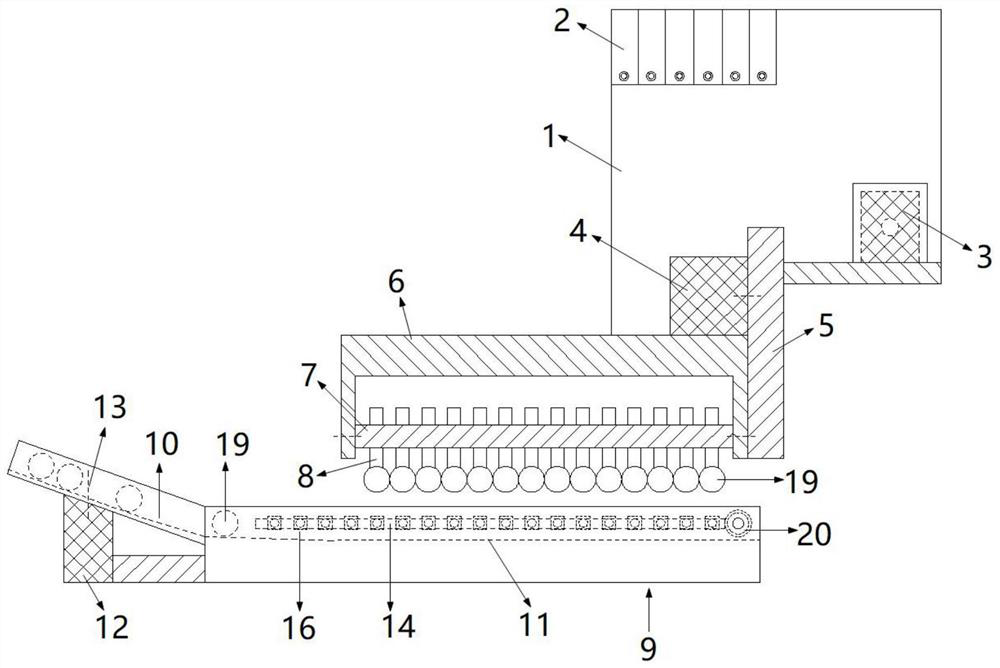

[0032] In the entire mating system of the present invention, it is also included in the transfer, positioning, and passed multi-directional transfer cylinder blocks, and placed the adsorbed controlled glass bottles in the capped pharmaceutical bottle, the main process content is as follows .

[0033] Placement positioning of the carton: manually put the forming carton into the lifting assembly, lifting a single carton one by one by one, and then conducts the carton to the belt module, the belt module allows the carton to position the carton by the clamping mechanism [ The tenth of the carton is more common in the prior art of the paper box, and the conventional carton conduction is designed.

[0034] Controlled glass bottle of box operation: When the glass bottle is adsorbed by the suction cup module 8, the plurality of adsorbed controlled glass bottles are placed in the fixed-point position by moving the cylinder mechanism 3 and the corresponding linkage mechanism.

Embodiment 2

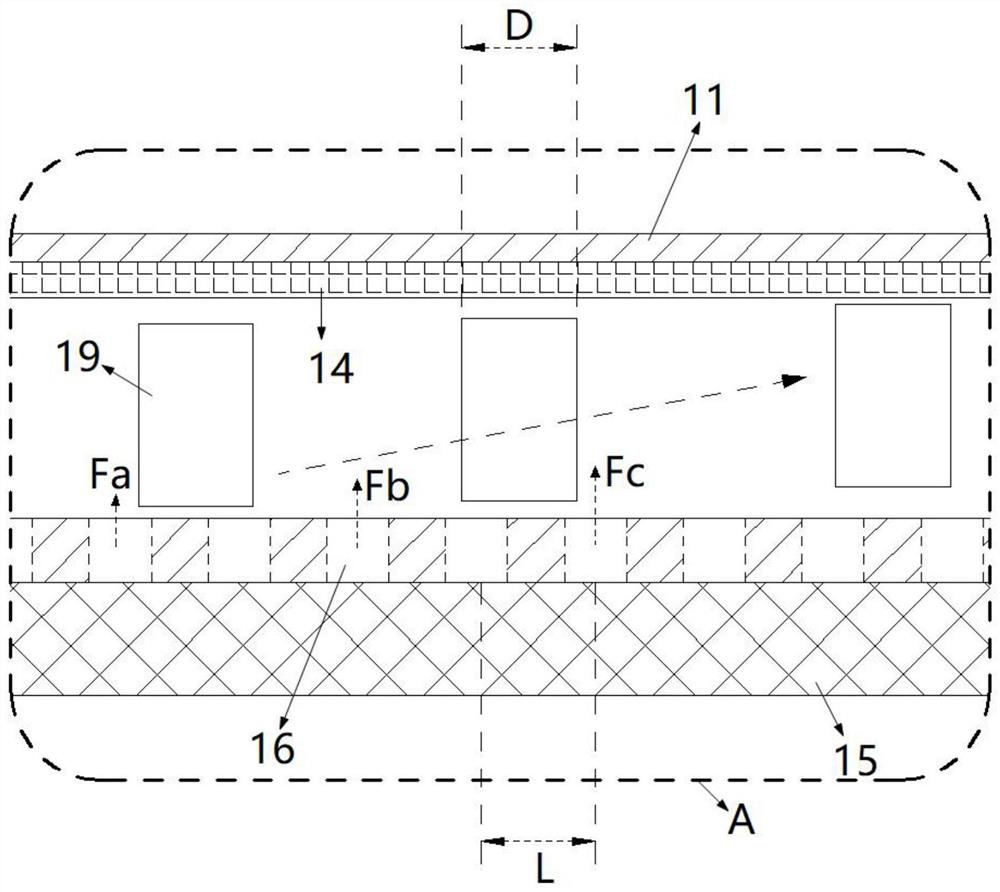

[0036]In the apparatus structure of the present invention, a plurality of pneumothy structures of the air supply regulatory mechanism 15 are opened, each with independent electromagnetic valve control, and the control of the glass bottle is constant. The more the position is close, the larger the air of the airpage of the corresponding position, increase the forward wind resistance and lateral force to the controlled glass bottle. Of course, the air supply in the present invention, the air volume blown out of the wind communication hole 16 belongs to the lower wind level, and the air supply is opened before the front side outlet hole 16 is reached, and [for example The wind, the controlled glass bottle will not only be affected by the wind resistance in front, but also from the continuous lateral [low level] wind effect, began to gradually rely toward the photoelectric position sensing strip 14 side, reach a decentralized position, with pole The low momentum is performed, "reducin...

Embodiment 3

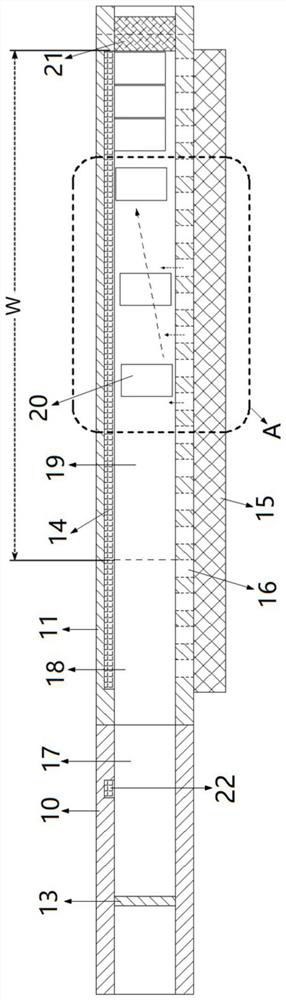

[0038] In the apparatus structure of the present invention, the barrier baffle 13 is mounted at a 2 / 3 height position of the bevel conductor frame 10, and cannot be disposed at the excessive position of the inclined guide frame 10, and the position is too low. The controlled glass bottle itself can be low, which may not be able to reach the integrated position of the horizontal face of the conductive platform.

[0039] The slope inclinement angle of the inclined slope 17 of the inclined conductive frame 10 is 15 to 30 °, and a segment microwal slope 18 is provided in the conductive platform, and the first is to be able to introduce a glass bottle into the established horizontal surface 19. 19 Inside, the size of the horizontal face 19 is designed according to the specifications of the controlled glass bottle, such as a roll glass bottle having a diameter size of M. The horizontal surface surface 19 width is W, and the horizontal surface 19 can be released N-controlled glass. Bottl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap