Wood cellulose-carbon nanotube composite filamentous biological filler for treating micro-polluted water source and preparation method of wood cellulose-carbon nanotube composite filamentous biological filler

A carbon nanotube composite and bio-filler technology, which is applied in the direction of water pollutants, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of poor treatment effect of micro-pollutants, achieve reduced replacement costs, strong adsorption effect, The effect of high-efficiency enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

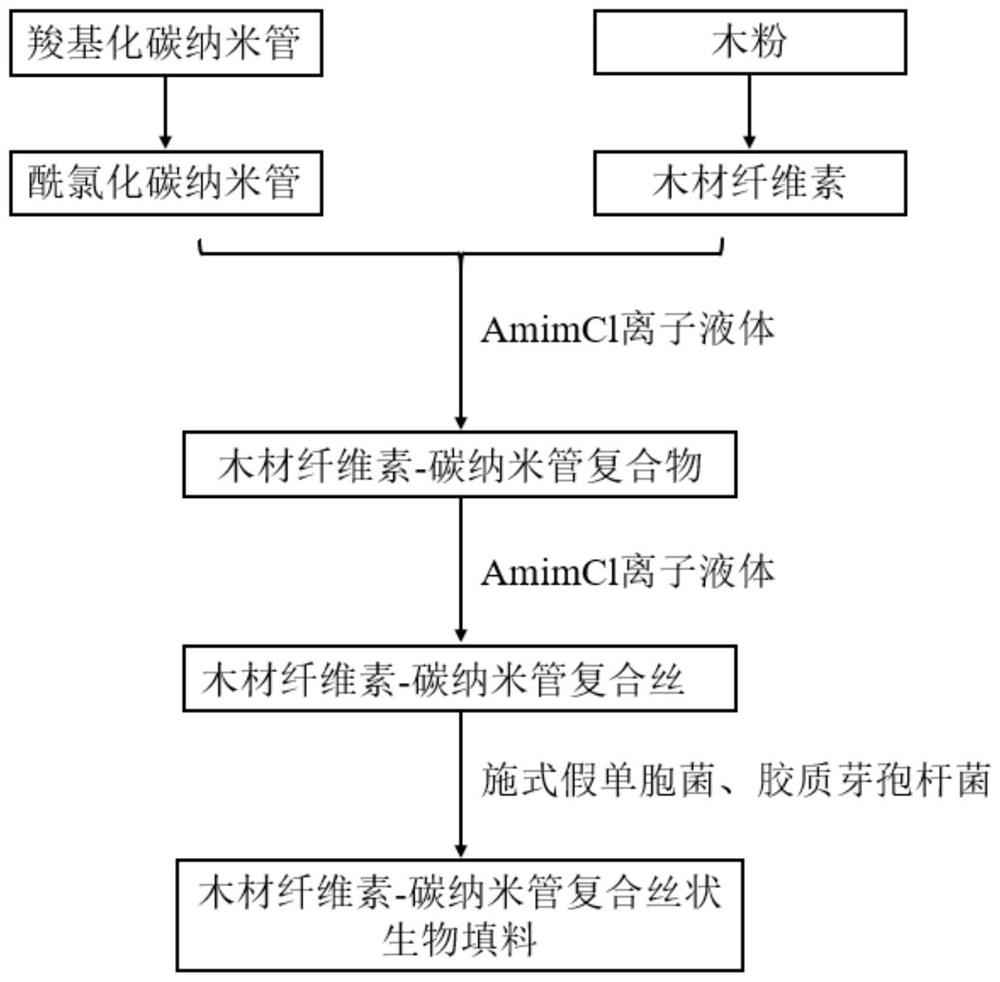

Method used

Image

Examples

Embodiment 1

[0039] Weigh 0.7 g of commercially available carboxylated carbon nanotube powder, put it into a three-necked flask, add 30 mL of thionyl chloride (SOCl 2 ), then add 1mL of N,N-dimethylformamide (DMF), control the temperature of the three-necked flask at 70°C, reflux for 24h, and then distill off the sample under reduced pressure at 90°C with a rotary evaporator. Thionyl chloride, the sample was taken out, washed with acetone repeatedly, and then the sample was filtered with a microporous membrane under reduced pressure until the filtrate was neutral by pH test. Then put it into a vacuum drying oven, vacuum-dry at 70° C., and grind to obtain carbonyl chloride carbon nanotubes after drying.

[0040] Slowly add 100mL of concentrated nitric acid into 400mL of absolute ethanol, mix thoroughly, and store in a brown reagent bottle for later use. Weigh 1g of dry wood powder, add 25mL of nitric acid-ethanol mixture, put it into a reflux condensing device, heat in a boiling water bath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com