Intumescent anti-corrosion admixture and preparation method thereof

An intumescent and admixture technology, applied in the field of building materials, can solve the problems of high energy consumption, high cost, and limited resources in production, and achieve the effects of increasing utilization, reducing dependence, and improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

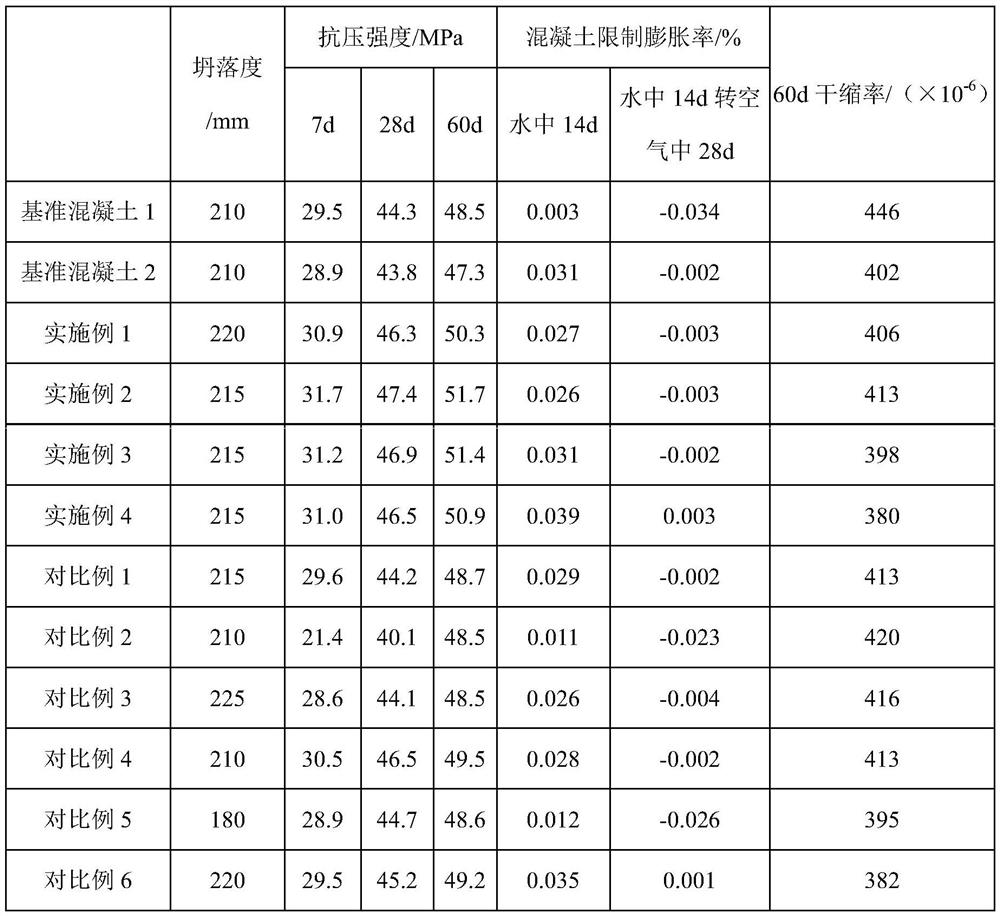

Embodiment 1

[0023] This embodiment provides an intumescent anti-corrosion admixture, which is made of the following raw materials in mass percentage: 60% fly ash, 20% slag powder (that is, the mass ratio of fly ash to slag powder is 3:1) , 13.97% light-burned magnesia, 5% calcium oxide expansion agent (the mass ratio of light-burned magnesia and calcium oxide expansion agent is 2.8:1), 1% gypsum, 0.03% sodium hexametaphosphate; The MgO content in calcined magnesia is 90.5%, the hydration activity value t is 120s, and the specific surface area is 275m 2 / kg, 1.18mm sieve residue is 0.2%; free calcium oxide (f-CaO) content is 55.2% in the described calcium oxide expansion agent, specific surface area is 256m 2 / kg, 1.18mm sieve residue is 0.4%; the gypsum is anhydrite;

[0024] The preparation method of described intumescent anti-corrosion additive comprises the following steps:

[0025] S1. Weigh the light-burned magnesia, calcium oxide expansion agent, gypsum, and sodium hexametaphospha...

Embodiment 2

[0028] This embodiment provides an intumescent anti-corrosion admixture, which is made of the following raw materials in mass percentage: 46% fly ash, 40% slag powder, 5.07% light-burned magnesium oxide, 7.9% calcium oxide expansion agent, 1% gypsum, 0.03% sodium hexametaphosphate; the MgO content in the light-burned magnesia is 89.3%, the hydration activity value t is 150s, and the specific surface area is 305m 2 / kg, 1.18mm sieve residue is 0.2%; free calcium oxide (f-CaO) content is 58.5% in the described calcium oxide expansion agent, specific surface area is 287m 2 / kg, 1.18mm sieve residue is 0.4%; the gypsum is desulfurized gypsum;

[0029] The preparation method of the intumescent anti-corrosion admixture is basically the same as that in Example 1. In step S1, the premixing time of light-burned magnesia, calcium oxide expansion agent, gypsum, and sodium hexametaphosphate is 10 minutes, and it is obtained after grinding The specific surface area of fly ash is measured ...

Embodiment 3

[0031] This embodiment provides an intumescent anti-corrosion admixture, which is made of the following raw materials in mass percentage: 50% fly ash, 30% slag powder, 7.985% light-burned magnesium oxide, 10% calcium oxide expansion agent, 2% gypsum, 0.015% sodium hexametaphosphate; the MgO content in the light-burned magnesia is 89.3%, the hydration activity value t is 200s, and the specific surface area is 296m 2 / kg, 1.18mm sieve residue is 0.3%; free calcium oxide (f-CaO) content is 57.4% in the described calcium oxide expansion agent, specific surface area is 291m 2 / kg, 1.18mm sieve residue is 0.3%; the gypsum is hemihydrate gypsum;

[0032] The preparation method of the intumescent anti-corrosion additive is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com