Plastic for hydrogen storage pressure vessel and preparation method thereof

A technology for pressure vessels and plastics, which is applied in the field of plastics for hydrogen storage pressure vessels and its preparation, can solve the problems affecting the mechanical properties, low modulus and strength of composite high-pressure hydrogen storage cylinders, low-pressure blasting of plastic linings, etc. Tensile strength and elongation at break, simple preparation method, and effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

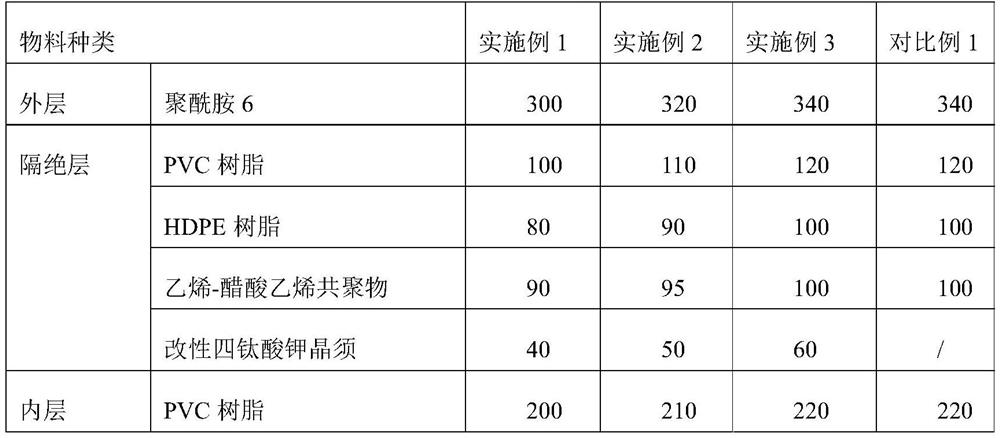

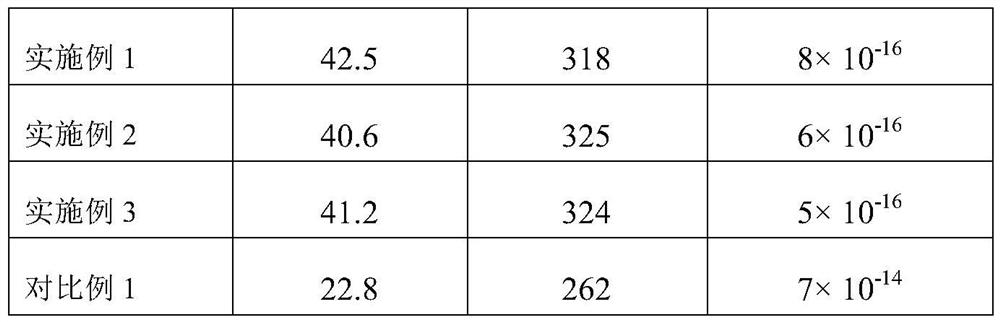

Embodiment 1

[0023] According to Table 1, the specific raw material is weighed, and the rest of the steps are as follows:

[0024] (1) Add a polyamide 6 to the mold to obtain an outer layer at a temperature of 300 ° C, and the mold is 30 min, and the air is cooled to 80 ° C;

[0025] (2) Add PVC resin, HDPE resin, ethylene-vinyl acetate copolymer, modified potassium potassium perfusulation, and to obtain a separation layer at a temperature of 260 ° C, and the rolling time is 50 min, and the wind is cool. 80 ° C;

[0026] (3) Add a PVC resin to the mold, and the inner layer is obtained at a temperature of 70 ° C, and the hipping time is 40 min, and the wind is cooled to 65 ° C, which is deprived.

Embodiment 2

[0028] According to Table 1, the specific raw material is weighed, and the rest of the steps are as follows:

[0029] (1) Add a polyamide 6 to the mold, and the outer layer is obtained at a temperature of 310 ° C, and the hipping time is 25 min, and the air is cooled to 70 ° C;

[0030] (2) Add PVC resin, HDPE resin, ethylene-vinyl acetate copolymer, modified tetral titanated potassium-calcium crystal, and to obtain a separation layer at temperature 260 ° C, the roll mode is 40 min, and the wind is cool. 70 ° C;

[0031] (3) Add a PVC resin to the mold, and the inner layer is obtained by rolling molding at a temperature of 75 ° C, and the hydrating time is 30 min, and the air is cooled to 60 ° C, which is obtained.

Embodiment 3

[0033] According to Table 1, the specific raw material is weighed, and the rest of the steps are as follows:

[0034] (1) Add a polyamide 6 to the mold to obtain an outer layer at a temperature of 310 ° C, and the hipping time is 30 min, and the air is cooled to 80 ° C;

[0035] (2) Add PVC resin, HDPE resin, ethylene-vinyl acetate copolymer, modified tetral titanated potassium-calcium, and the temperature is 50 min, and the temperature is 50 min, and the wind is cool. 80 ° C;

[0036] (3) Add PVC resin to the mold, and obtain the inner layer at a temperature of 75 ° C, the inner layer is obtained, and the water is 40 min, and the air is cooled to 65 ° C, which is deprived.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com