A prefabricated concrete subway station

A prefabricated assembly and concrete technology, applied in construction, artificial islands, excavation, etc., can solve the problems of large labor resources and raw materials consumption, poor on-site working environment, and large impact on road traffic, achieving fast construction speed, less wet work, The effect of high bearing capacity

Active Publication Date: 2022-05-31

SHANDONG UNIV +3

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Most subway stations are constructed by the open-cut method, which consumes a large amount of labor resources and raw materials. The construction site and material transportation have a great impact on road traffic, the degree of industrialization is low, the on-site operating environment is poor, and environmental pollution, noise pollution and other problems caused by construction increasingly serious

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

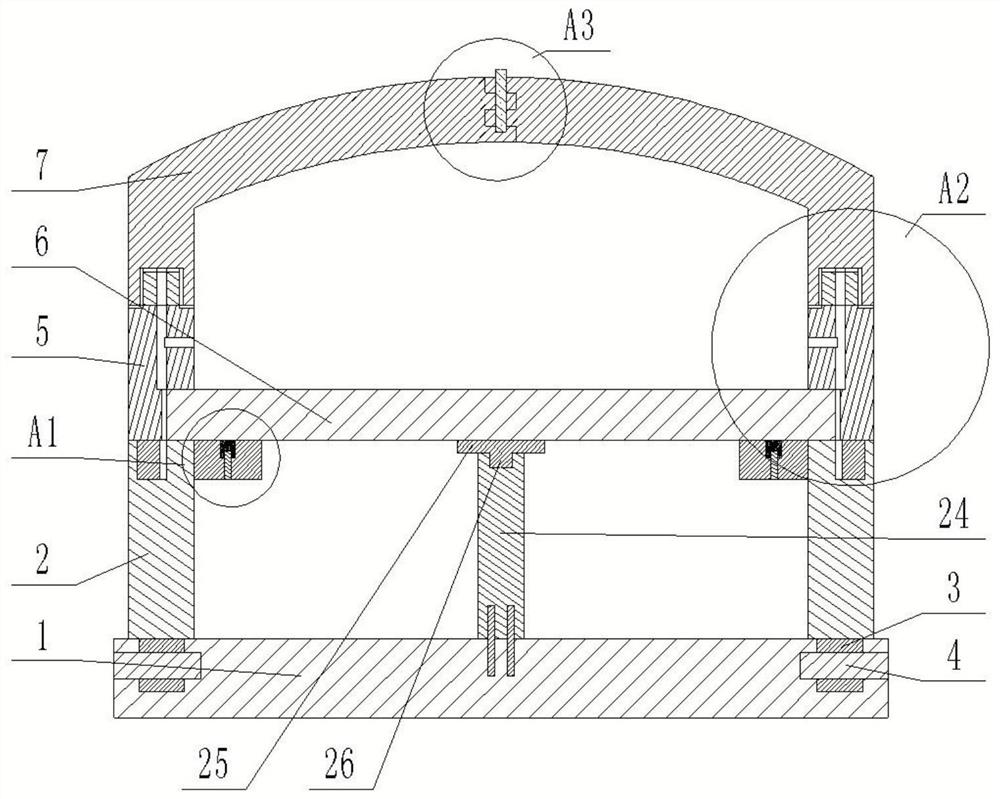

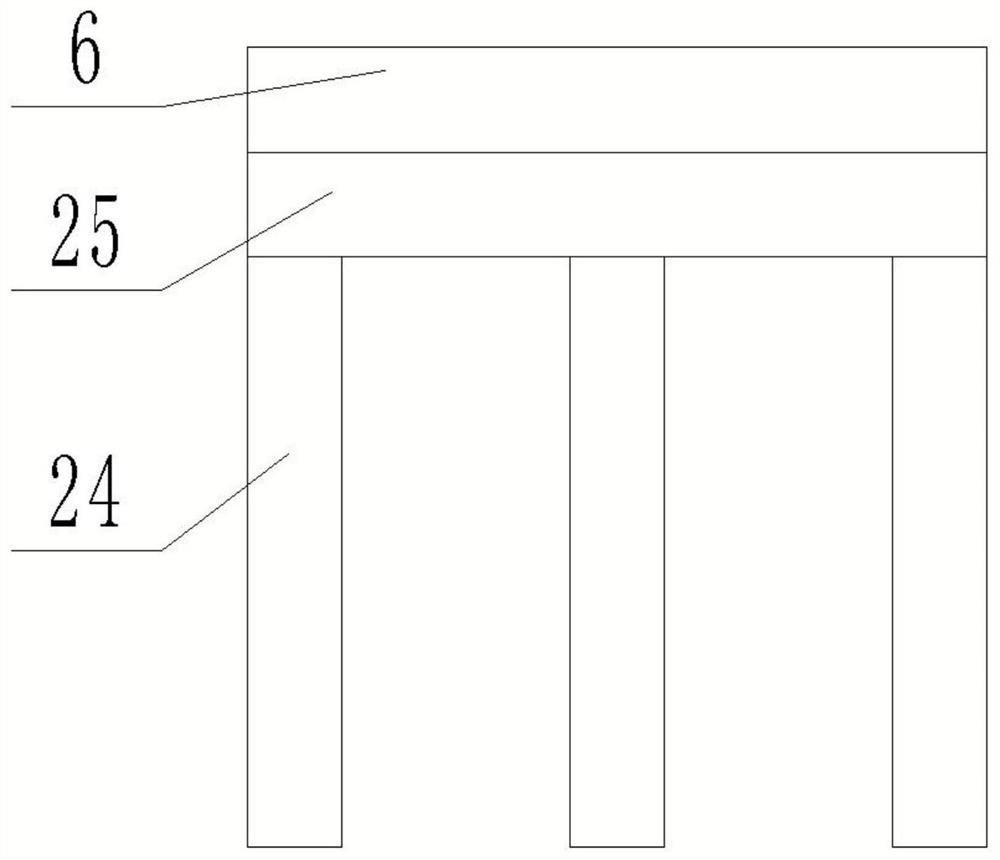

[0039] The support column 24 and the base plate 1 are fixed by support bolts.

Embodiment 2

Embodiment 3

[0043] Referring to FIG. 8, the prefabricated panel 6 includes a first reinforcing bar layer 28 and a second reinforcing bar layer 29, the first reinforcing bar layer 28 and the second reinforcing bar

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

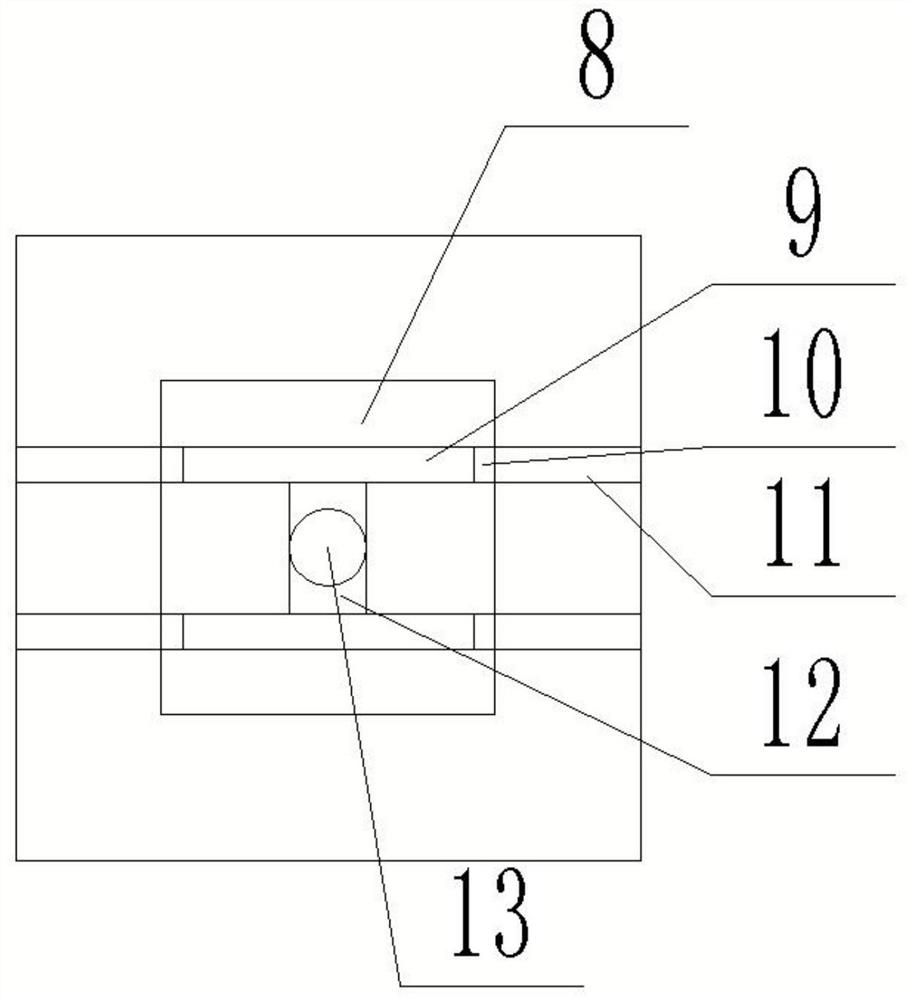

The invention discloses a prefabricated concrete subway station, which comprises a plurality of assembly units spliced in sequence. The assembly unit includes: a base plate, the base plate is arranged in a foundation pit, and lower side plates are respectively arranged on both sides of the top surface of the base plate, and the bottom surface of the lower side plate is fixed. Connected with a plug-in block, the two sides of the top surface of the base plate are respectively provided with slots matching the plug-in block, and the two sides of the base plate are respectively provided with plug-in holes. The other end passes through the plug-in block and is connected with the plug-in block through threads. The top of the lower side plate is provided with an upper side plate, and a prefabricated plate is arranged between the upper side plate and the lower side plate. device, the side of the positioning device is fixedly connected to the top of the side of the lower side plate, the upper side plate is provided with a connecting device, the top surfaces of the two upper side plates are respectively provided with a top plate, and a reinforcing device is provided between the two opposite sides of the two top plates, prefabricated A support device is provided at the center of the bottom surface of the board, and the bottom surface of the support device is detachably connected to the top surface of the substrate.

Description

A prefabricated concrete subway station technical field [0001] The present invention relates to the technical field of subway stations, in particular to a prefabricated concrete subway station. Background technique [0002] The subway station mostly adopts the open-cut method construction, which needs to consume a large amount of labor resources and raw materials, and the construction site and Material transportation has a great impact on road traffic, the degree of industrialization is low, the on-site working environment is poor, and the environmental pollution caused by construction, Problems such as noise pollution are becoming more and more serious. The prefabricated subway station can realize the standardization of design, prefabricated components and construction, which will greatly Greatly shorten the construction period of subway stations, reduce the area of construction materials stacking, processing, etc., and reduce a large amount of concrete pouring. On...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E02D29/045E02D29/00E02D17/02E02D15/02E02D29/16

CPCE02D29/045E02D29/04E02D17/02E02D15/02E02D29/16

Inventor 郭相武龚斯昆姜晓明胡学龙胡云飞黄鹏王光伟王夏冰徐祥云张真煌刘薇何俊王跃王培军刘芳州

Owner SHANDONG UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com