Method for improving oil well productivity through nano system composite CO2 huff and puff

A technology for CO2 and oil wells, applied in wellbore/well components, chemical instruments and methods, and production fluids, etc., can solve the problems of reducing permeability, achieve the effects of reducing permeability, replenishing formation energy, and avoiding deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Well P8 in an oilfield, the effective thickness of the oil layer is 7.1m, the average porosity is 25.4%, and the average permeability is 16×10 -3 μm 2 , the reservoir temperature is 50°C, the reservoir pressure is 10.41MPa, and the surface crude oil density is 0.9319t / m 3 , ground crude oil viscosity 765.52mPa.s, freezing point 39 ℃.

[0040] Nano solution injection amount Q is: V=3.14R 2 Hфβ=3.14×7.1 2 ×10×0.254×0.8=558m 3 , where: R takes a value of 10, and β takes a value of 0.8. Calculation of liquid CO according to the gas-liquid ratio of 2:1 2 The injection volume is 1116t.

[0041] Construction steps:

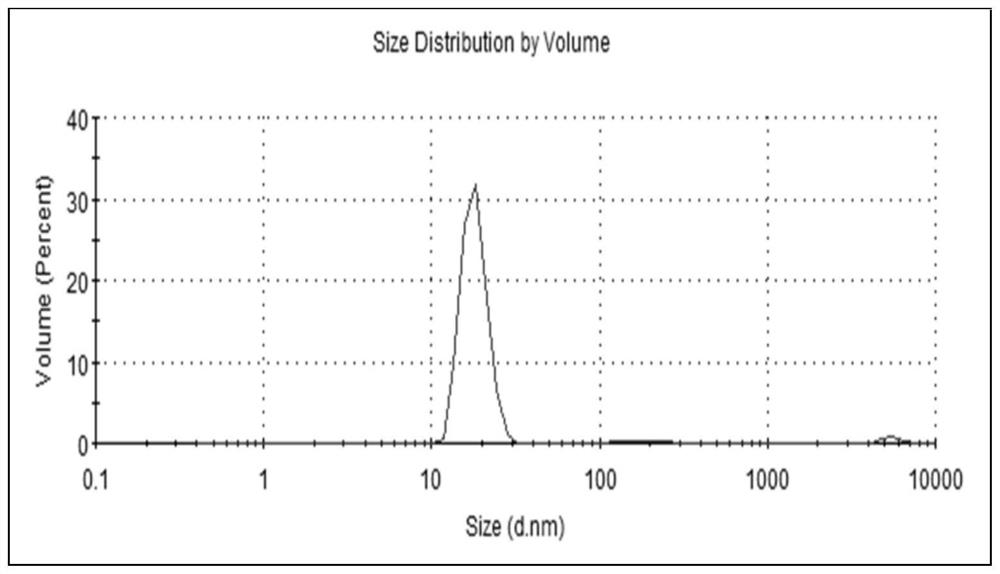

[0042] (1) The solid content of the prepared nanoparticles is 0.005% water-based nano-solution: the water-based nano-solution is composed of the following components according to the mass percentage: 0.005% nano-SiO 2 Particles, 3% fluorine-containing silicone (perfluorosiloxane with a methoxy end group and a carbon chain length of 6), 0.3% fluorocarbon su...

Embodiment 2

[0052] Well P11 in an oilfield, the oil layer has an effective thickness of 4.8m, an average porosity of 24.3%, and an average permeability of 27×10 -3 μm 2 , the reservoir temperature is 50°C, the reservoir pressure is 10.41MPa, the surface crude oil density is 0.9457t / m3, the surface crude oil viscosity is 896.62mPa.s, and the freezing point is 40°C.

[0053] Nano solution injection amount Q is: V=3.14R 2 Hфβ=3.14×4.8 2 ×20×0.243×0.8=281m 3 , where: R takes a value of 20, and β takes a value of 0.8. Calculation of liquid CO according to the gas-liquid ratio of 2:1 2 The injection volume is 563t.

[0054] Construction steps:

[0055] (1) Prepare the water-based nanometer solution with embodiment 1.

[0056] (2) Use a pump truck to inject the water-based nano-solution into the formation through the oil jacket annulus, with an injection displacement of 40m 3 / d, use the method of day injection and night stop, so that the nano solution can fully interact with the formati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com