A wind turbine and its centralized lubrication system

A technology for wind turbines and lubrication systems, which is applied in wind turbines, wind power generation, engines, etc., and can solve problems such as failure of the friction pairs of wind turbines to be lubricated normally, extended working hours of maintenance personnel, heat generation and even fires, etc., to reduce bearings The probability of wear and tear and the probability of heat and fire, saving working time and fan downtime, and the effect of convenient and quick fat replenishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

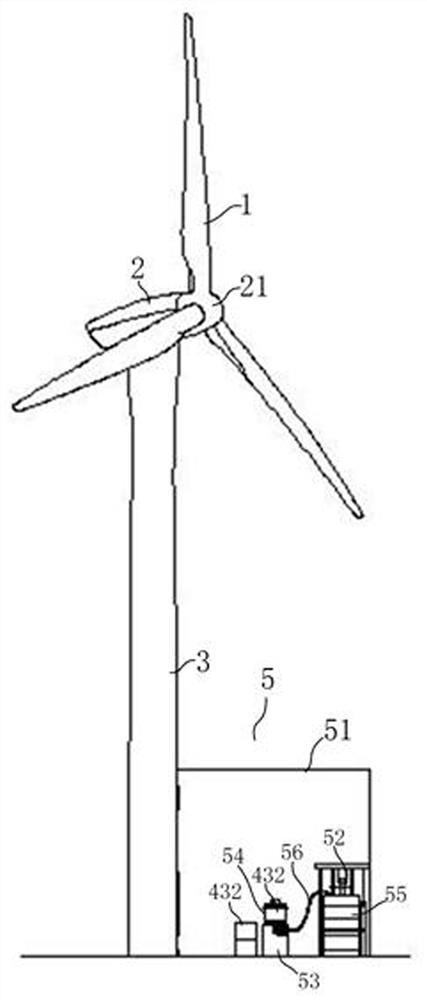

[0065] like figure 1As shown, the wind turbine includes a wind wheel 1, a generator, a pitch mechanism, a yaw mechanism, a tower 3, a nacelle 2, a grid-connected connection device and a centralized lubrication system, wherein the generator, the pitch mechanism, and the yaw mechanism . The grid-connected connection device is not shown in the figure, and the above mechanisms are all in the prior art, and will not be repeated here.

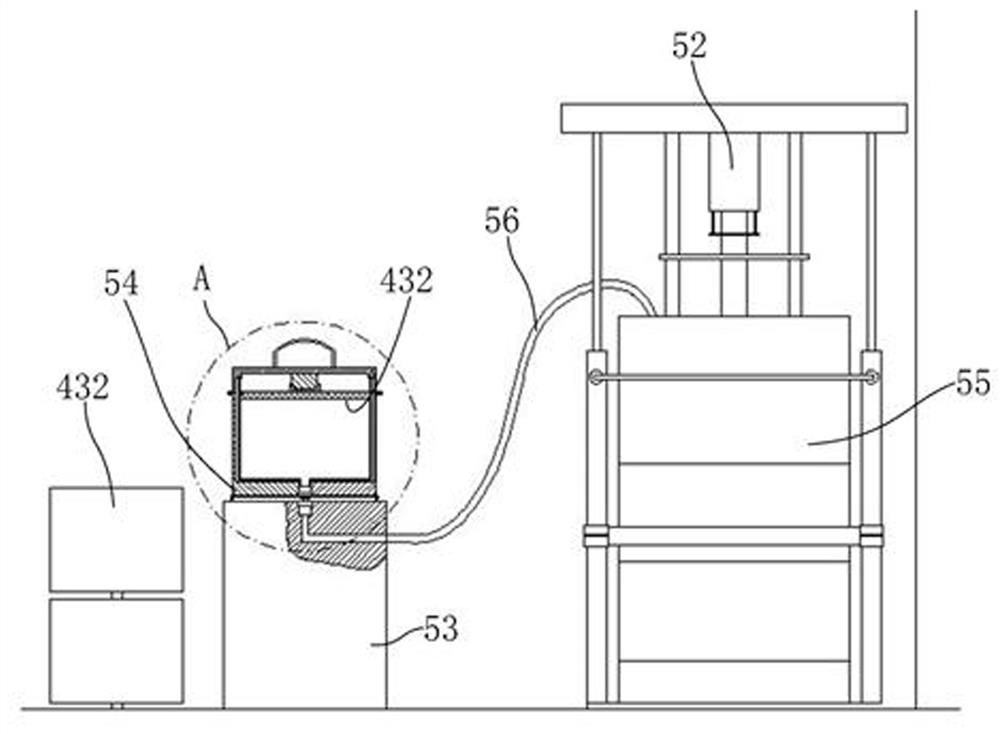

[0066] like figure 1 , 2 , 5, the centralized lubrication system includes a lubrication system 4 for adding grease to each bearing of the wind turbine and a grease replenishing system 5 for replenishing the oil tank 432 with grease. The lubrication system 4 is fixedly installed in the engine room 2 , and the grease replenishing system 5 is located at the bottom of the tower 3 .

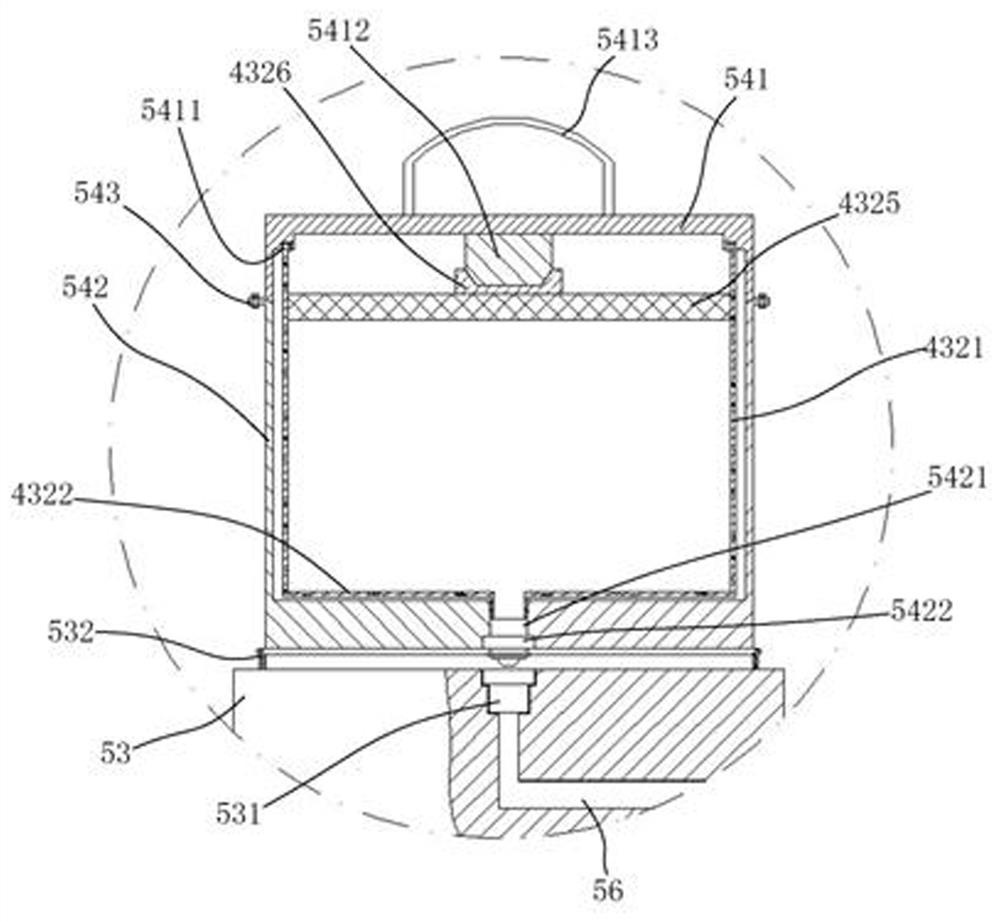

[0067] like Figure 5 As shown, the lubrication system 4 includes a lubrication pump 43 , a distributor 41 and a lubrication line 42 . The lubricating pump 43 is a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com