Flushing system and flushing method for secondary circuit of high-temperature gas cooled reactor

A high-temperature gas-cooled reactor and flushing system technology, applied in the field of nuclear power, can solve the problems of increasing the difficulty of flushing wastewater control and processing costs, and achieve the effects of flexible flushing control methods, reduced wastewater discharge, and improved flushing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

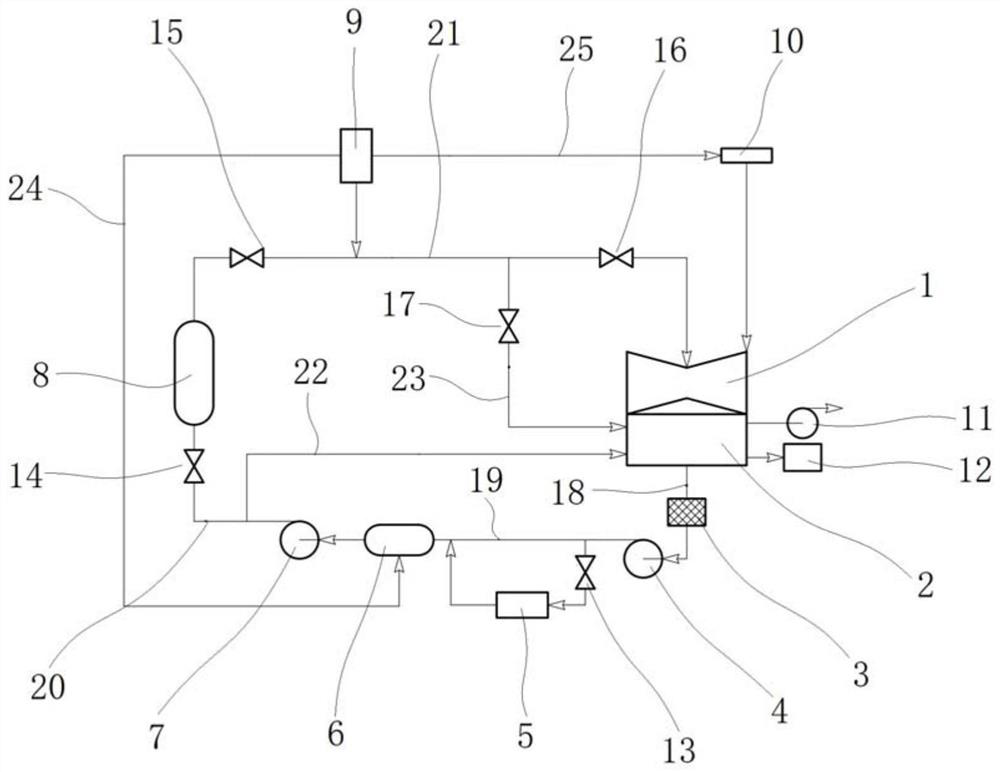

[0046] This embodiment provides a specific implementation of the high temperature gas-cooled reactor secondary loop flushing system, such as figure 1 As shown, the flushing system includes a steam turbine 1 , a condenser 2 , a condensate pump 4 , a deaerator 6 , a feed water pump 7 and a steam generator 8 . The steam turbine 1 communicates with the condenser 2, the condenser 2 communicates with the condensate pump 4 through a first pipeline 18, and the condensate pump 4 communicates with the deaerator through a second pipeline 19 6, the deaerator 6 communicates with the feedwater pump 7 through a pipeline, the feedwater pump 7 communicates with the steam generator 8 through a third pipeline 20, and the steam generator 8 communicates with the steam generator 8 through a fourth pipeline The road 21 communicates with the steam turbine 1 . The fifth pipeline 22 is connected between the third pipeline 20 and the condenser 2, and the fifth pipeline 22 is connected to the position n...

Embodiment 2

[0054] This embodiment provides a specific implementation of the flushing method, using the flushing system in Example 1, comprising the following steps: closing the fourth valve 13 to isolate the finishing device 5, closing the first valve 14, and the second valve 15 to isolate Steam generator 8, close the third valve 16 to isolate the steam turbine 1, open the steam trap 17; start the condensate pump 4, so that the condensate in the condenser 2 passes through the first pipeline 18 and the second pipeline 19 to the deaerator 6 , and then start the feed water pump 7 to return the feed water in the deaerator 6 to the condenser 2 through part of the third pipeline 20 and the fifth pipeline 22, so as to realize the cold cycle flushing of the secondary circuit water system; start the electric boiler 9, Part of the steam generated by the electric boiler 9 enters the condenser 2 through the steam trap 17, and performs hot flushing on the fourth pipe. At the same time, the steam heats...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com