High-speed amorphous alloy permanent magnet motor

An amorphous alloy, permanent magnet motor technology, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problem of high mechanical strength requirements of the rotor, and achieve the effects of superior performance, reduced motor iron loss, and reliable mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

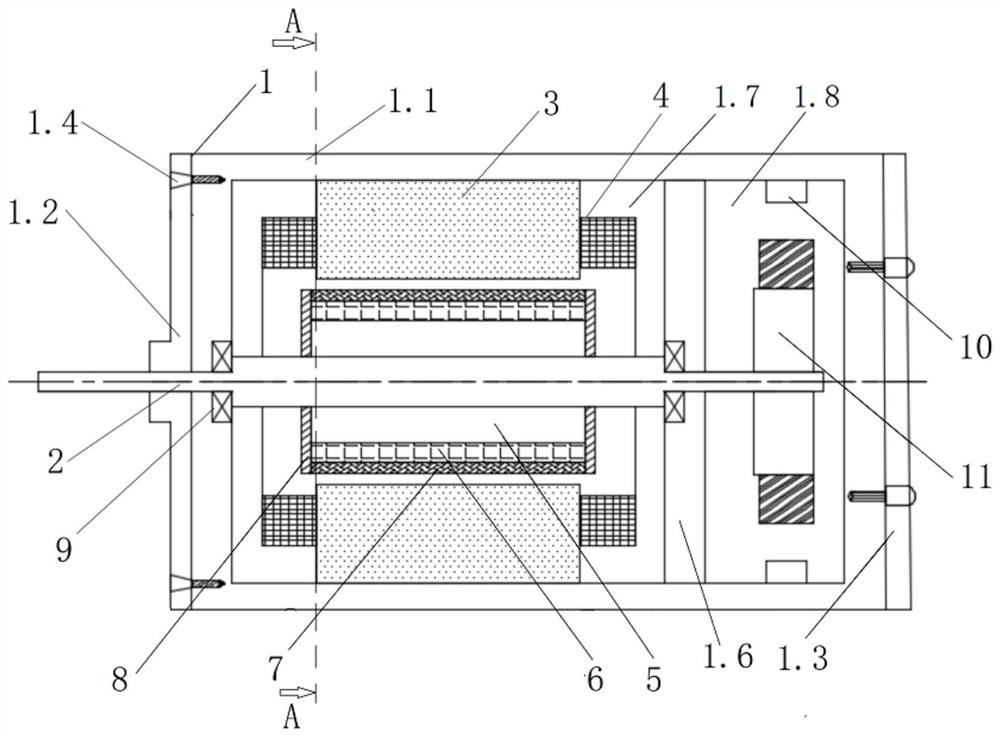

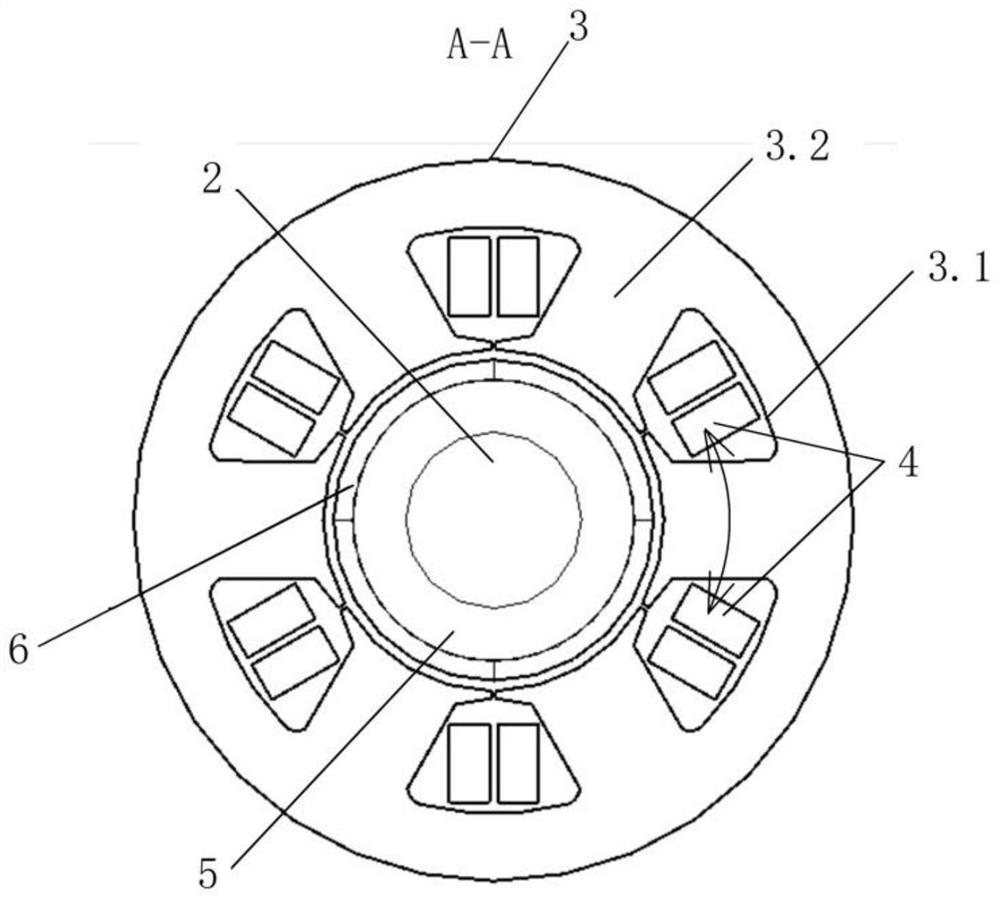

[0027] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will be more clearly understood through description. All deformations that can be derived or associated directly from the disclosed content of the present invention by those skilled in the art should be considered as the protection scope of the present invention. The positional relationships described in the embodiments are consistent with those shown in the accompanying drawings, and other parts not described in detail in the embodiments are all prior art.

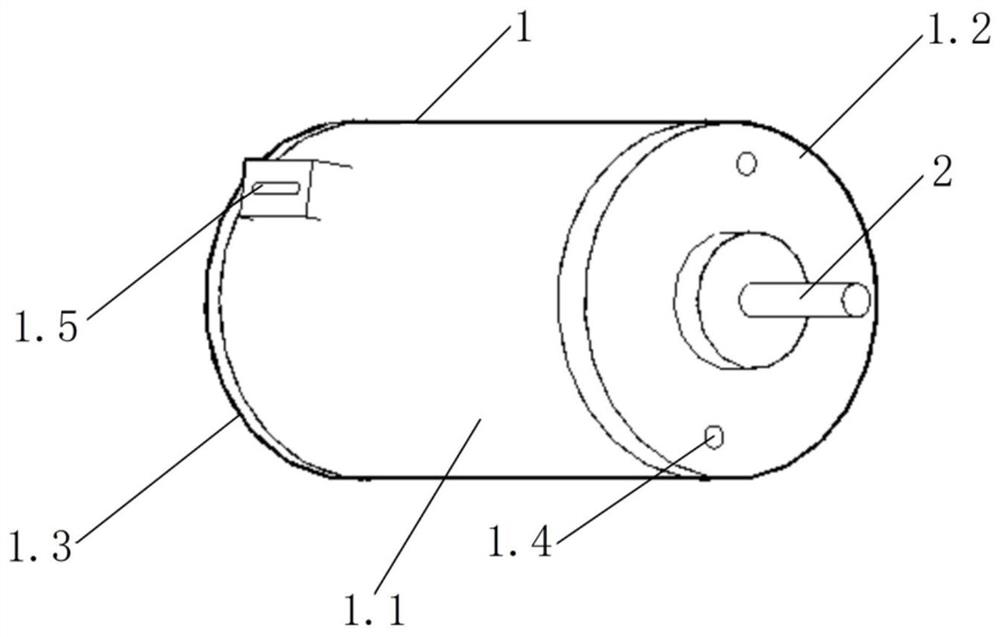

[0028] The high-speed amorphous alloy permanent magnet motor is composed of a motor casing 1, a motor body and a position sensor arranged in the motor casing.

[0029] The structure of the motor casing 1 is as figure 1 and figure 2 As shown, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com