Magnetic nanorod with ordered large mesoporous polymer shell layer and synthesis method of magnetic nanorod

A technology of magnetic nanorods and synthesis methods, applied in medical preparations of non-active ingredients, inorganic non-effective ingredients, chemical instruments and methods, etc., can solve the problems of limited application, single silicon-based shell structure, etc., and achieve surface modification properties, unique spontaneous shear stirring, and controllable mesoscopic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

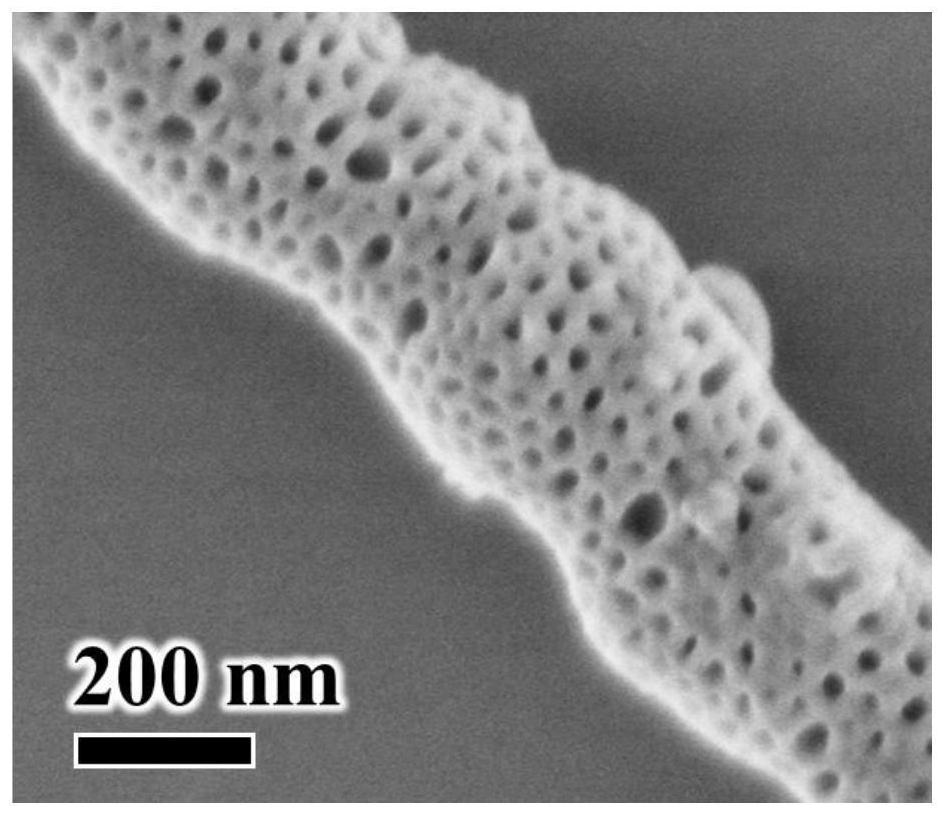

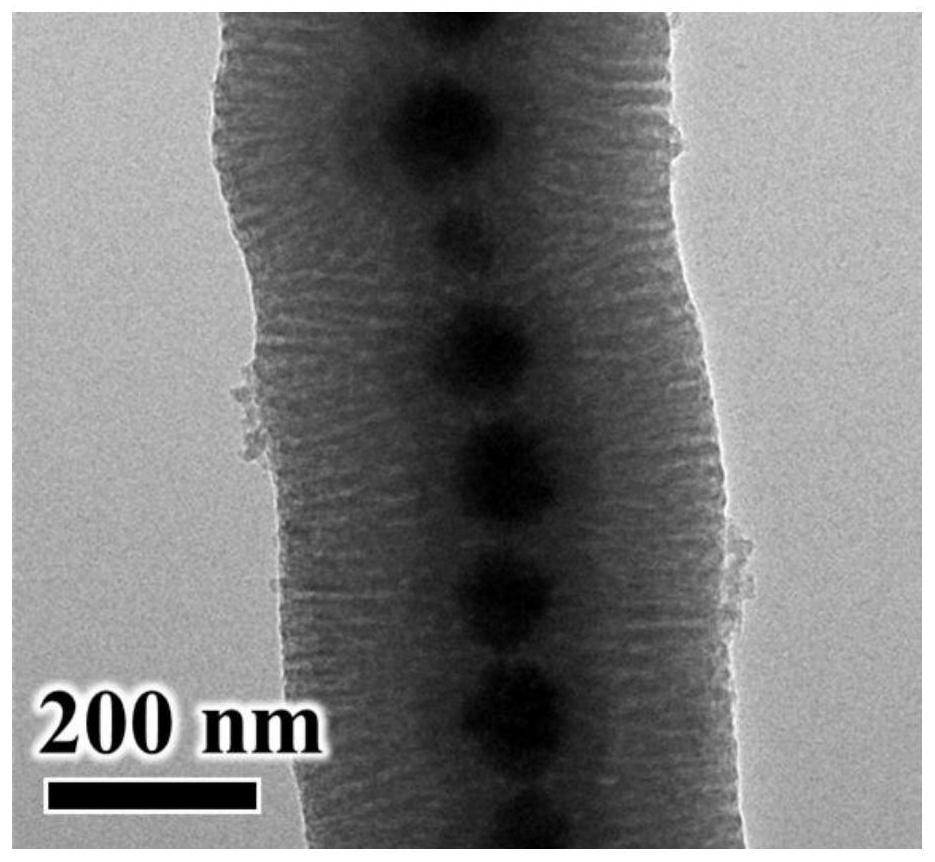

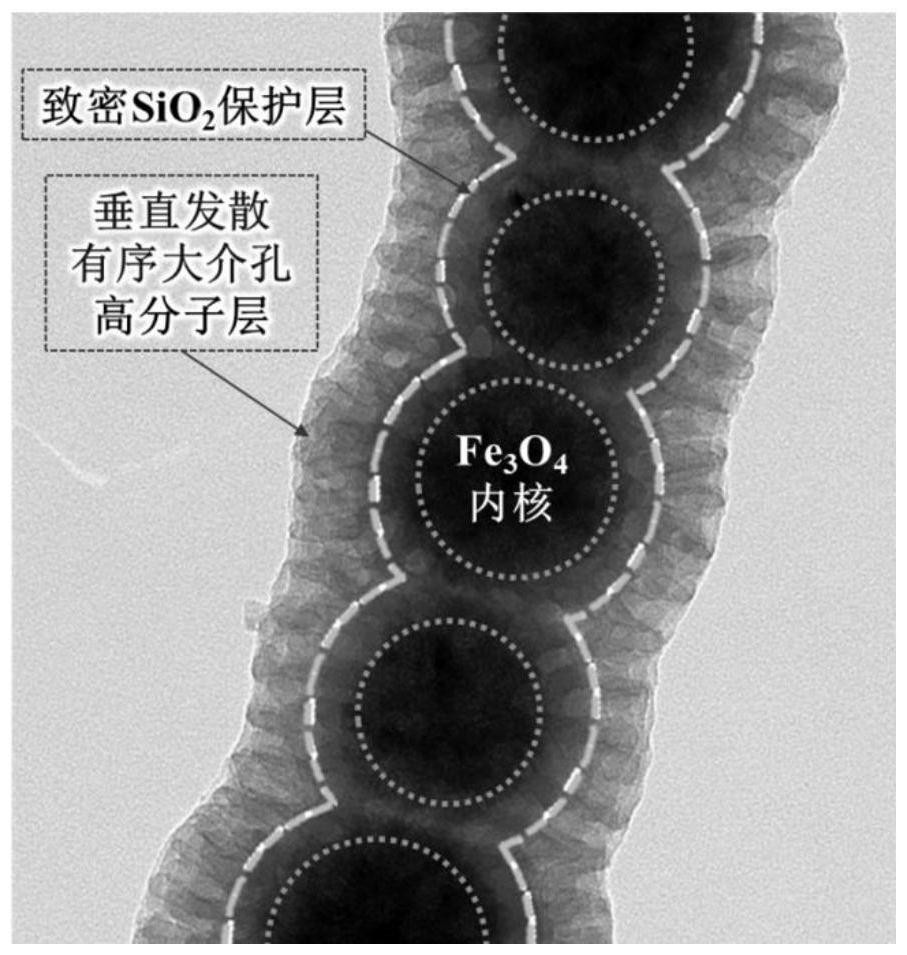

[0036] This embodiment provides a magnetic nanorod with an ordered large mesoporous polymer shell and a synthesis method thereof.

[0037] The method for synthesizing the magnetic nanorods with ordered large mesoporous polymer shells comprises the following steps:

[0038] In step A, 50 mg of magnetic ferric oxide particles with a particle size of about 50 nm were added to 90 mL of ethanol for ultrasonic dispersion, mechanically stirred at 350 rpm for 30 min, and quickly added to 4.5 mL of concentrated ammonia water (28 wt.%); The rotation speed was increased to 700 rpm and vigorously stirred for 10 min, then the rotation speed was adjusted back to 350 rpm, and 0.45 mL TEOS was added dropwise, and the stirring was stopped at 350 rpm for 15 min. After that, it was placed in a stable magnetic field (15 mT) for 90 s, and then the magnetic field was removed. After standing for 8 h, a magnetic nanorod with a layer of silicon dioxide deposited on the surface was obtained. The produc...

Embodiment 2

[0044] This embodiment also provides a magnetic nanorod with an ordered large mesoporous polymer shell and a synthesis method thereof.

[0045] The method for synthesizing the magnetic nanorods with ordered large mesoporous polymer shells comprises the following steps:

[0046] Step A, add 50 mg of magnetic γ-iron sesquioxide particles with a particle size of about 200 nm into 60 mL of ethanol for ultrasonic dispersion, mechanically stir at 350 rpm for 30 min, and quickly add 6 mL of concentrated ammonia water (28 wt.%); Immediately increase the rotational speed to 700 rpm and vigorously stir for 10 min, then adjust the rotational speed back to 350 rpm, and add 0.9 mL TEOS dropwise, and stir at 350 rpm for 15 min, then stop stirring. After that, it was placed in a stable magnetic field (30 mT) for 90 s, and then the magnetic field was removed. After standing for 8 h, a magnetic nanorod with a layer of silicon dioxide deposited on the surface was obtained. The product was separ...

Embodiment 3

[0051] This embodiment also provides a magnetic nanorod with an ordered large mesoporous polymer shell and a synthesis method thereof.

[0052] The method for synthesizing the magnetic nanorods with ordered large mesoporous polymer shells comprises the following steps:

[0053] In step A, 50 mg of magnetic NiFe with a particle size of about 500 nm 2 o 4 Particles were added to 90 mL of ethanol for ultrasonic dispersion, mechanically stirred at 350 rpm for 30 min, and quickly added to 9 mL of concentrated ammonia water (28 wt.%); immediately increased the speed to 700 rpm and stirred vigorously for 10 min, then returned the speed to 350 rpm, and 0.9 mL TEOS was added dropwise, and stirred at 350 rpm for 15 min, then the stirring was stopped. After that, it was left to stand in a stable magnetic field (60 mT) for 180 s, and then the magnetic field was removed. After standing for 8 h, a magnetic nanorod with a layer of silicon dioxide deposited on the surface was obtained. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com