Ceramic milling cutter suitable for rough machining

A milling cutter and ceramic technology, which is applied in the field of ceramic cutters for rough machining of nickel-based superalloys, can solve problems such as groove wear and bond wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Nickel-based high-temperature alloys have extremely high strength and hardness. When the cutting speed is only 30-60m / min, the processing efficiency of cemented carbide tools is extremely low. When the cutting speed increases, the cutting temperature will also increase sharply. When the cutting temperature reaches 800°C, the surface of the nickel-based superalloy workpiece will have a thermal softening effect, and the strength and hardness of the workpiece material will be greatly reduced. The loss of cobalt in the binder phase in the tool will increase the bonding wear of the tool, resulting in sharp wear of the tool, a significant decrease in life, and even an instantaneous failure of the tool that cannot be used.

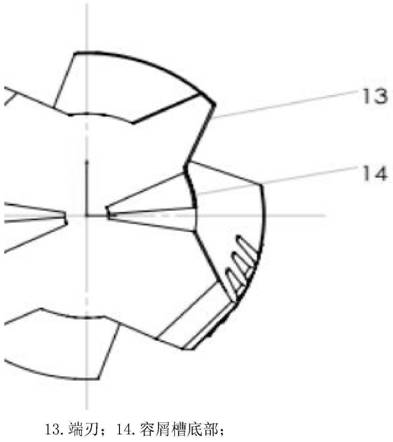

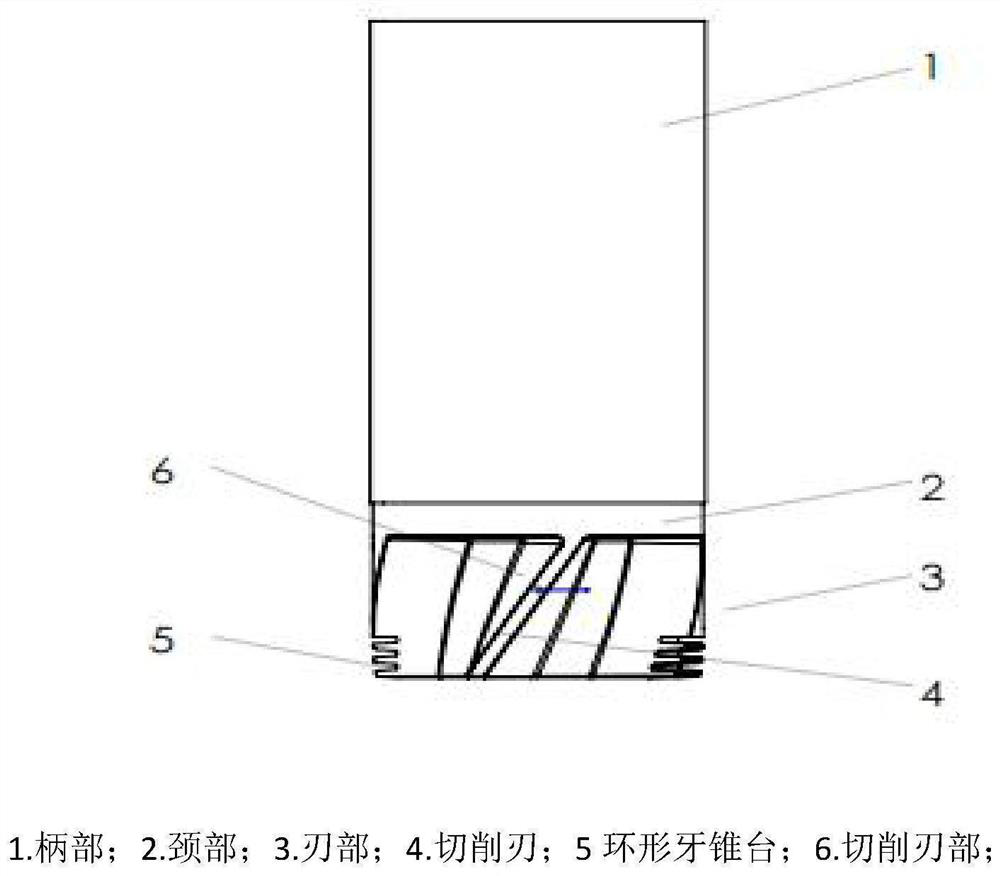

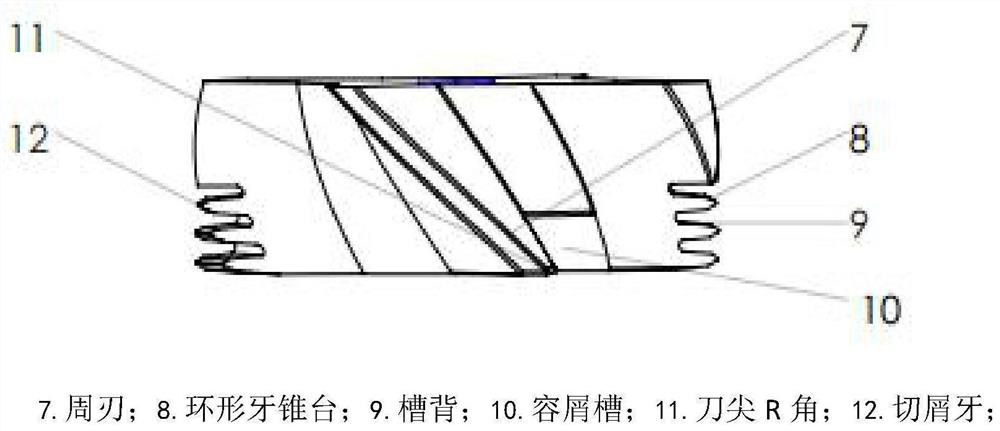

[0024] The present invention is a ceramic milling cutter suitable for rough machining, which aims to replace the currently widely used cemented carbide cutter and ceramic cutter by changing the structure of the common integral ceramic milling cutter, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Angle angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com