A kind of 3D printing wave structure shape memory composite material and its preparation method

A technology of 3D printing and composite materials, which is applied in the field of 3D printing wave structure shape memory composite materials and its preparation, can solve the problems of composite materials with special structures, complex process and high cost, etc., and achieve low-frequency magnetic field shielding performance improvement and material The molding process is simple and the finished product quality is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

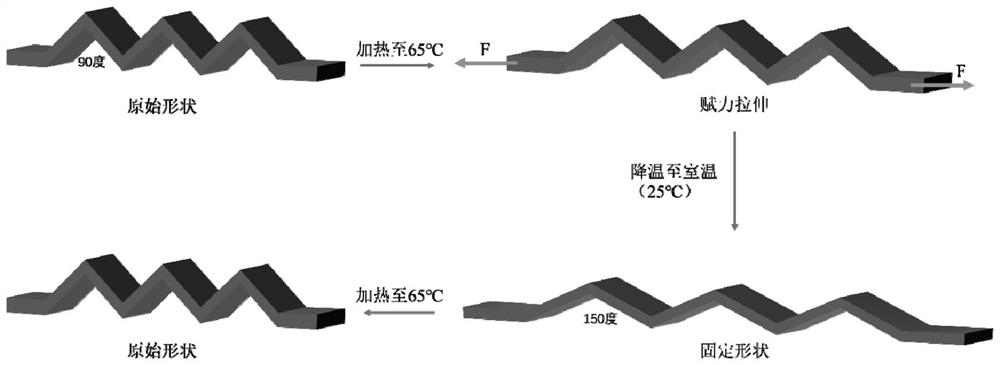

[0028] A preparation method of the 3D printing wave structure shape memory composite material, the preparation method comprises the following steps:

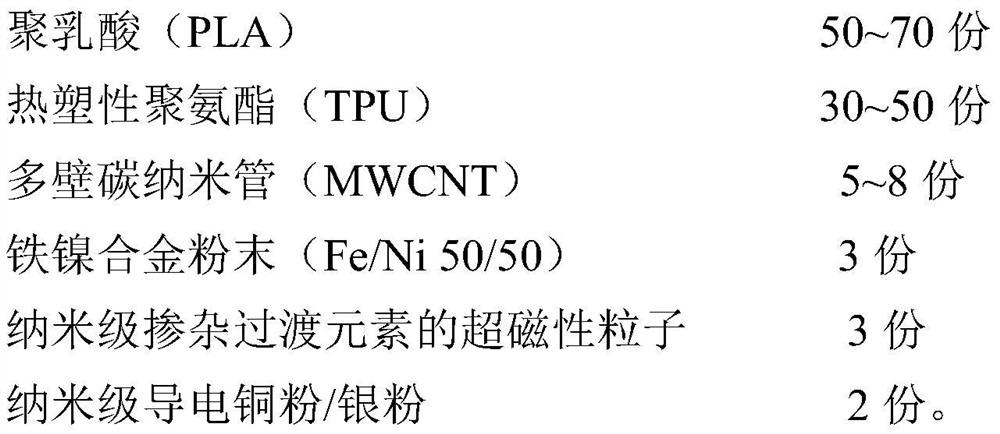

[0029] (1) 50 parts of polylactic acid (PLA), 50 parts of thermoplastic polyurethane (TPU), 5 parts of multi-walled carbon nanotubes (MWCNT), 3 parts of iron-nickel alloy powder (Fe / Ni 50 / 50), 3 parts of nanoscale V-Fe 3 O 4 After weighing with 2 parts of nano-scale conductive copper powder according to the proportion, they were respectively placed in an oven for pre-baking at 65 ℃ for 10 hours;

[0030] (2) The pre-baked raw materials were mechanically mixed for 2 hours at a speed of 800 r / min, added to the feed port of the single-screw extruder, preheated for 0.5 hours at startup, and the preheating temperature of the single-screw extruder was adjusted to 210 ℃, the extrusion head temperature is 180℃ and the extrusion speed is 100r / min, the raw materials are melted and blended and extruded to prepare 3D printing wires with u...

Embodiment 2

[0038] A preparation method of the 3D printing wave structure shape memory composite material, the preparation method comprises the following steps:

[0039] (1) 50 parts of polylactic acid (PLA), 50 parts of thermoplastic polyurethane (TPU), 6 parts of multi-walled carbon nanotubes (MWCNT), 3 parts of iron-nickel alloy powder (Fe / Ni 50 / 50), 3 parts of nanoscale Zr-Fe 3 O 4 After weighing with 2 parts of nano-scale conductive copper powder according to the proportion, they were respectively placed in an oven for pre-baking at 65°C for 9 hours;

[0040] (2) The pre-baked raw materials were mechanically mixed for 1.5 hours at a rotational speed of 780 r / min, added to the feed port of the single-screw extruder, and preheated for 0.5 hours at the start of the machine, and the preheating temperature of the single-screw extruder was adjusted to be 205°C, extrusion head temperature of 175°C and extrusion speed of 90r / min, melt and blend the raw materials and extrude them to prepare...

Embodiment 3

[0045] A preparation method of the 3D printing wave structure shape memory composite material, the preparation method comprises the following steps:

[0046] (1) 50 parts of polylactic acid (PLA), 50 parts of thermoplastic polyurethane (TPU), 8 parts of multi-walled carbon nanotubes (MWCNT), 3 parts of iron-nickel alloy powder (Fe / Ni 50 / 50), 3 parts of nanoscale Co-Fe 3 O 4 After weighing with 2 parts of nano-silver powder according to the proportion, they were respectively placed in an oven for pre-baking at 65°C for 8h;

[0047] (2) The pre-baked raw materials are mechanically mixed for 1.5 hours at a rotational speed of 700 r / min, added to the feed port of the single-screw extruder, and preheated for 0.5 hours at the start of the machine. Adjust the preheating temperature of the single-screw extruder to be 215°C, the extrusion head temperature is 185°C, and the extrusion speed is 80r / min, the raw materials are melt-blended and extruded to prepare 3D printing wires with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com