Carbon-containing waste gasification furnace and gasification method of carbon-containing waste

A gasification furnace and waste technology, which is applied in the field of carbon-containing waste gasification furnace and carbon-containing waste gasification, can solve the problems of complex pretreatment process, high cost, energy waste, etc., and improve gasification efficiency and energy utilization, save energy input, and reduce the effect of carbon residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

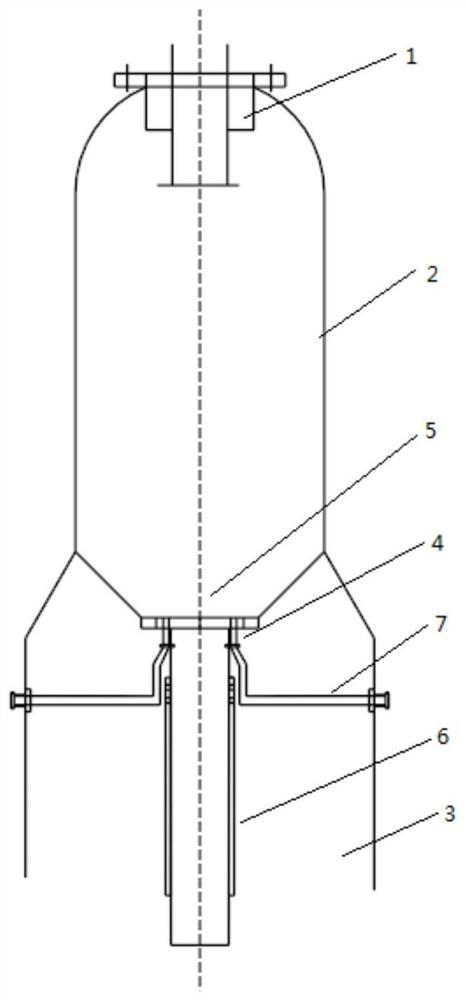

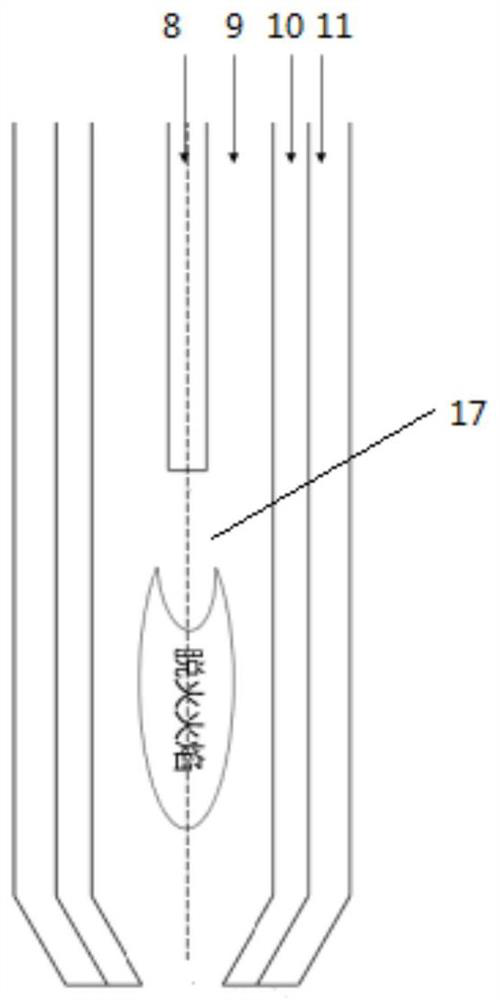

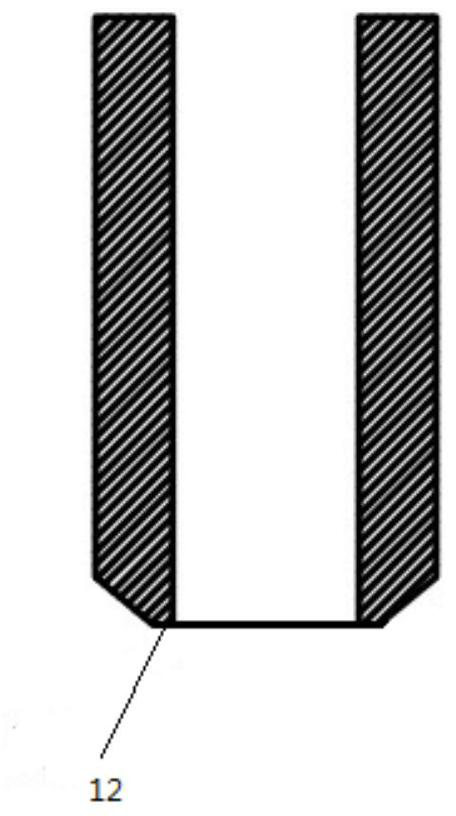

[0054] refer to Figure 1-5 , using a gasifier as described above for gasification of carbonaceous waste. Wherein, the wall thickness of the outlet end face of the central annular channel 8 of the gasifier is 0.5 mm, the purge port 16 is set so that the included angle between the injection direction and the central axis of the gasifier is 45 degrees, and the injected purge gas has a temperature of 400 ℃ water vapor; the outlet direction of the bottom of the second annular channel 10 and the third annular channel 11 and the central axis of the burner 1 form an included angle of 55 degrees.

[0055] In this embodiment, the combustible waste gas passed into the central annular passage 8 of the burner 1 is coke oven gas, the oxidant passed into the first annular passage 9 and the third annular passage 11 is oxygen; The input combustible carbon-containing waste is slurry made of solid combustible carbon-containing waste and liquid combustible carbon-containing waste.

[0056] Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com