Supercritical carbon dioxide turbine rotor radial supporting system

A turbine rotor and carbon dioxide technology, applied in steam engine devices, engine components, machines/engines, etc., can solve the problems of limited damping and lifting effect, limited effect, and inability to completely suppress rotor amplitude, etc., to achieve large radial support damping and avoiding amplitude Peak, simple structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

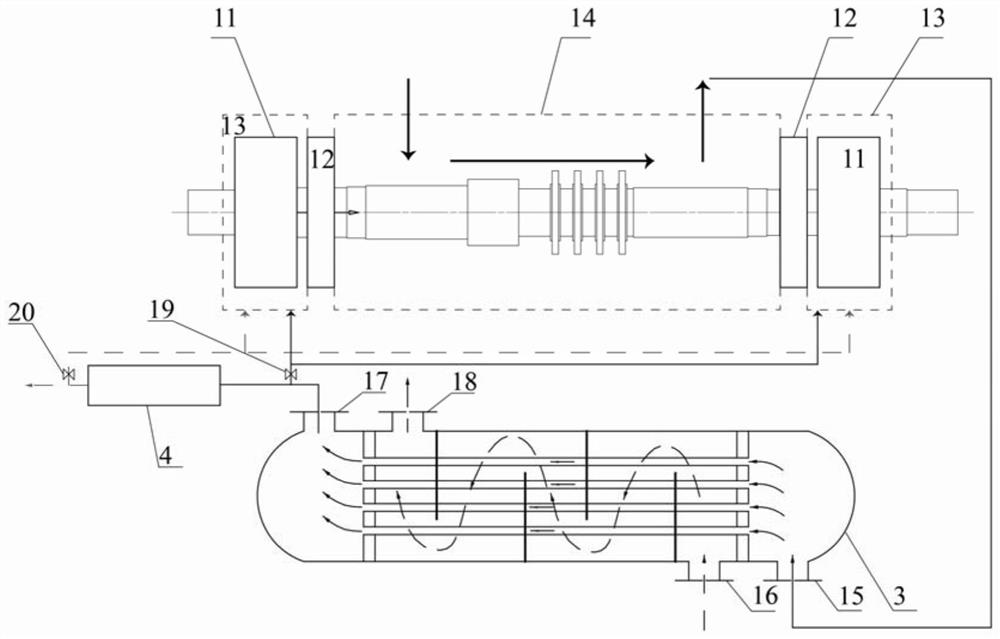

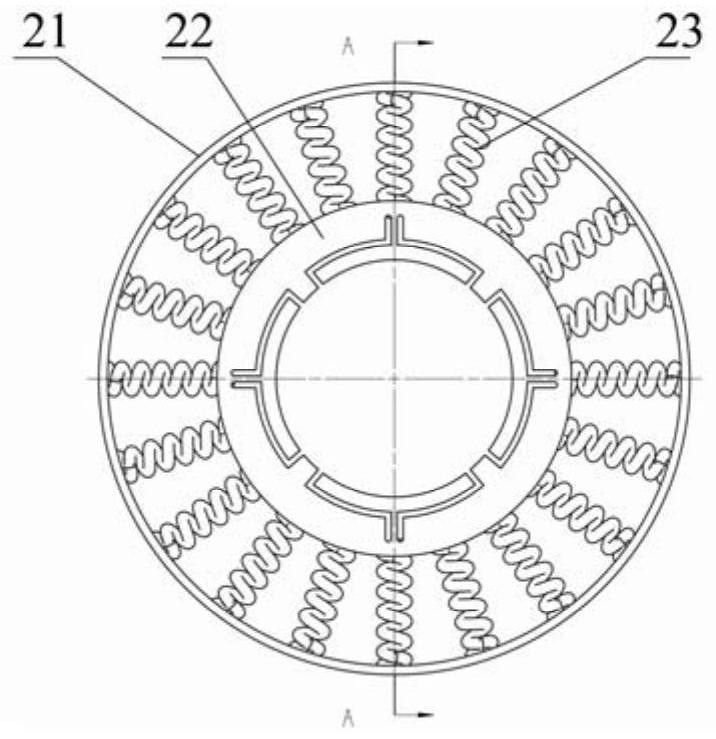

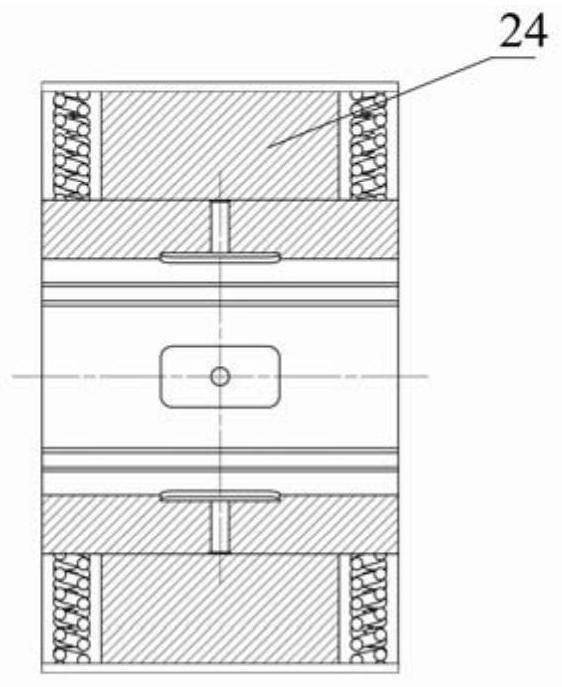

[0025] Such as figure 1 As shown, the present invention includes a turbine rotor 9, an eddy current displacement sensor and two bearing seats 13 (the number of bearing seats is not limited to two). The turbine rotor 9 is provided with two bearing support sections 91 (the number of bearing support sections 91 is the same as the number of bearing seats 13 ). Bearing housing 13 inner hole is provided with supporting shell 21, as Figure 2-4 As shown, the support shell 21 is provided with a radial tilting pad bearing 22, and between the outer wall of the bearing shell of the radial tilting pad bearing 22 and the support shell 21, multiple sets of shape memory alloy (SMA) springs 23 and a ring A wire mesh block 24, multiple groups of shape memory alloy springs 23 are evenly arranged along the circumferential direction, each group of shape memory alloy springs 23 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com