Engine-driven air source heat pump

An air-source heat pump and engine-driven technology, which is applied to refrigerators, compressors, compressors, etc., to achieve the effects of reducing energy consumption, reducing gas resistance, and reducing unit costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

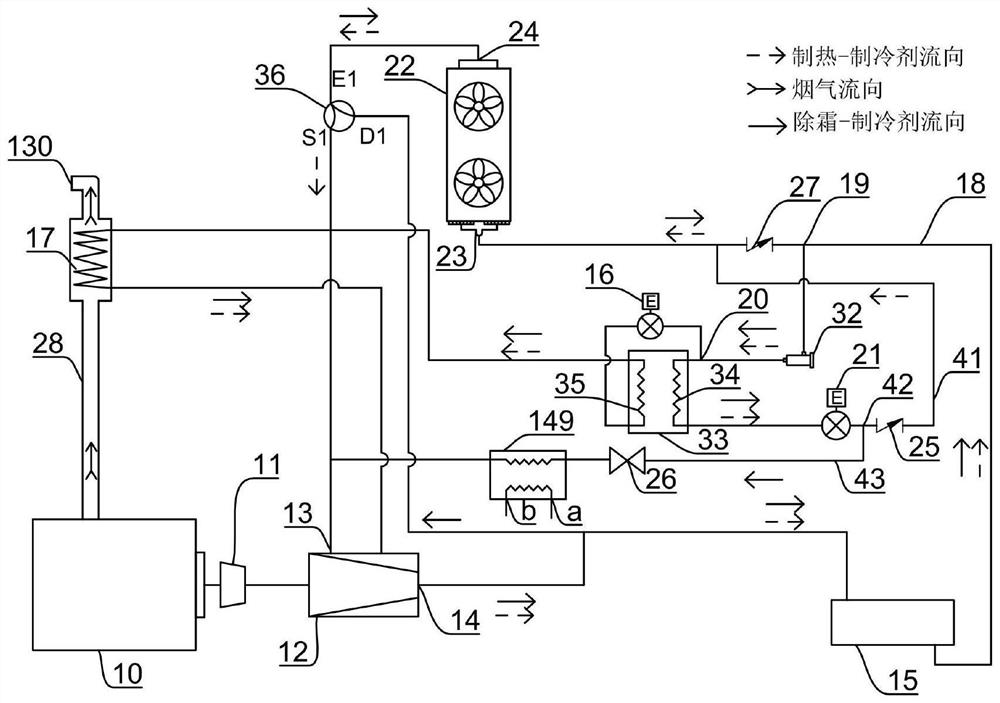

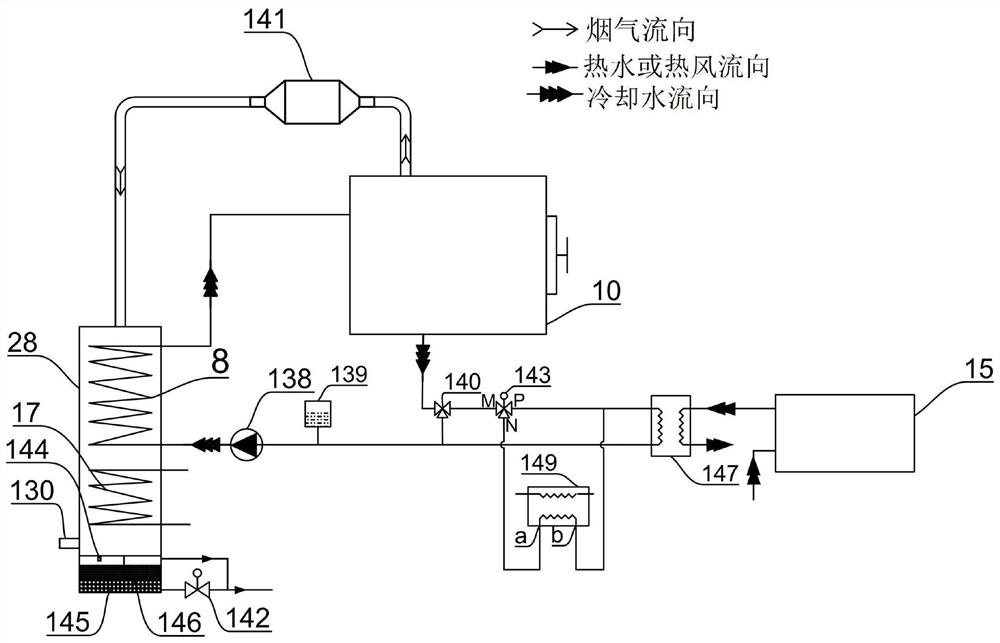

[0035] This embodiment provides an engine-driven air source heat pump. figure 1 It is a schematic diagram of the connection and flow chart of the main part of the engine-driven air source heat pump in Embodiment 1 of the present invention; figure 2 It is a schematic diagram of the connection and flow of the peripheral parts of the engine-driven air source heat pump in Embodiment 1 of the present invention.

[0036] Such as figure 1 and figure 2 As shown, the engine driven air source heat pump includes a main body portion and a peripheral portion. Among them, the main part includes engine 10, transmission device 11, compressor 12, first heat exchanger 15, first throttle valve 16, flue gas refrigerant heat exchanger 17, first pipeline 18, second throttle valve 21. The second heat exchanger 22 , the first switching valve 25 , the second switching valve 26 , the economizer 33 , the refrigerant three-way valve 36 , and the cooling water refrigerant heat exchanger 149 . The pe...

Embodiment 2

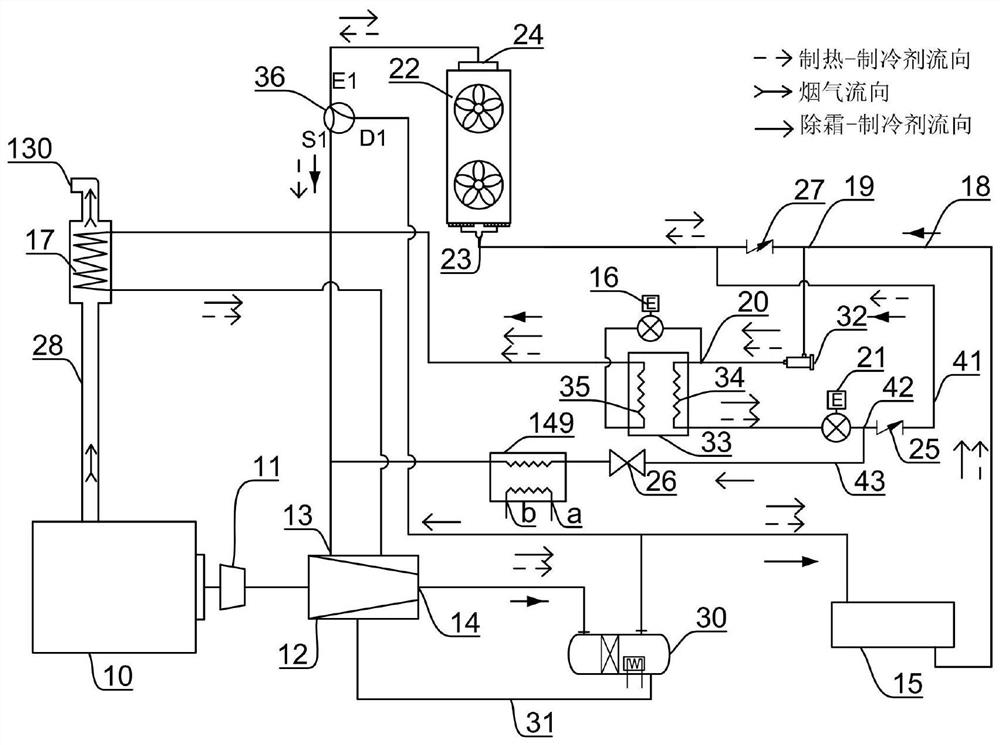

[0061] image 3 It is a schematic diagram of the connection and flow chart of the main part of the engine-driven air source heat pump in the second embodiment of the present invention.

[0062] Such as image 3 As shown, Embodiment 2 provides an engine-driven engine-driven air-source heat pump. The difference between the engine-driven air-source heat pump and Embodiment 1 is that the main part of the engine-driven air-source heat pump in this embodiment also includes an oil separator 30, lubricating oil circuit 31, dry filter 32. The first heat exchanger 15 of this embodiment does not include the oil separator 30 .

[0063] The other structures in this embodiment are the same as in Embodiment 1, and the same numbers are assigned to the same structures.

[0064] image 3 Among them, the oil separator 30 has an oil-separated refrigerant inlet, an oil-separated refrigerant outlet, and a lubricating oil discharge port, the oil-separated refrigerant inlet communicates with the ...

Embodiment 3

[0074] Figure 4 It is a schematic diagram of the connection and flow chart of the main part of the engine-driven air source heat pump in Embodiment 3 of the present invention.

[0075] Such as Figure 4 As shown, Embodiment 3 provides an engine-driven engine-driven air source heat pump. The difference between the engine-driven air source heat pump and Embodiment 1 is that the main part of the engine-driven air source heat pump in this embodiment also includes a fourth switch valve 38 , third heat exchanger 39 , and fifth switching valve 40 .

[0076] The other structures in this embodiment are the same as in Embodiment 1, and the same numbers are assigned to the same structures.

[0077] Figure 4 Among them, the first communication port 23 is connected to the second connection point 20 through the fourth switching valve 38 and the second throttle valve 21 , and the fourth switching valve 38 is closer to the first communication port 23 than the second throttle valve 21 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com