Wafer-level through-silicon-via packaging structure manufacturing method and through-silicon-via packaging structure

A technology of packaging structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as increasing costs, affecting product reliability, and stress affecting film quality, so as to reduce production costs and simplify Production process flow, effect of reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

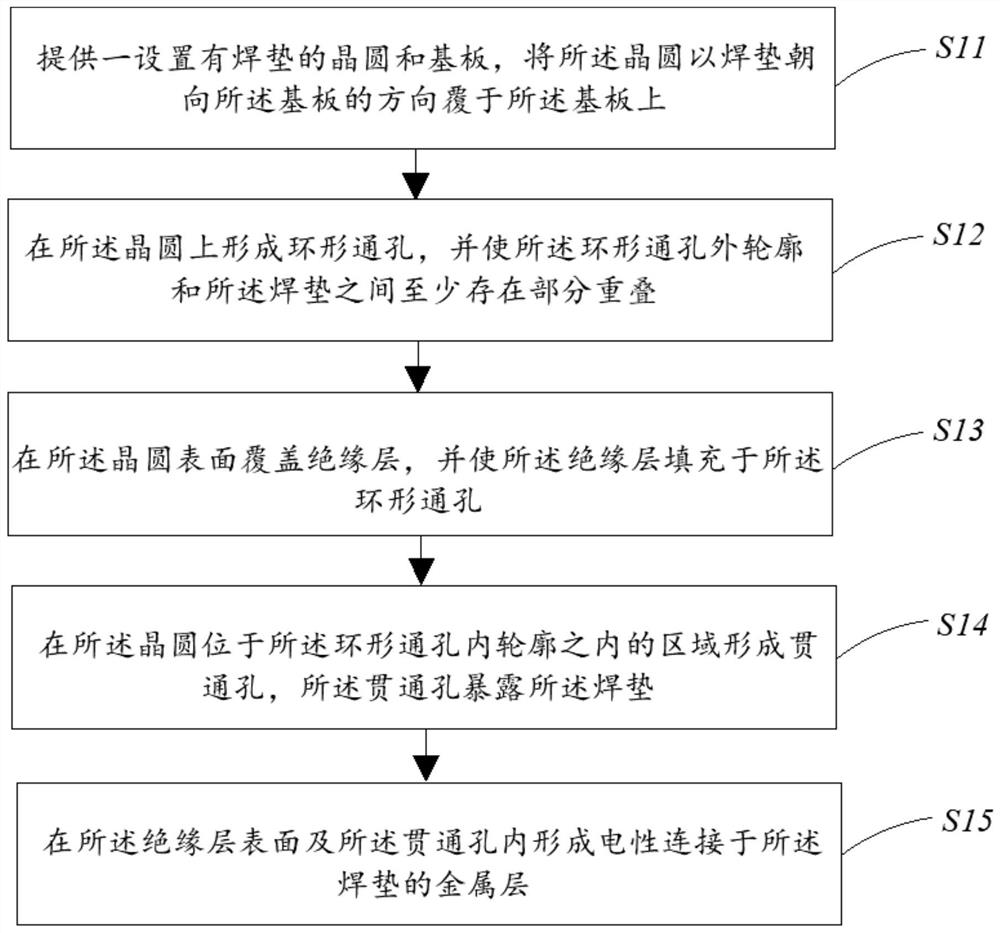

[0047] like figure 1 As shown, a method for manufacturing a 2-level through-silicon via packaging structure provided by Embodiment 1 of the present invention includes steps:

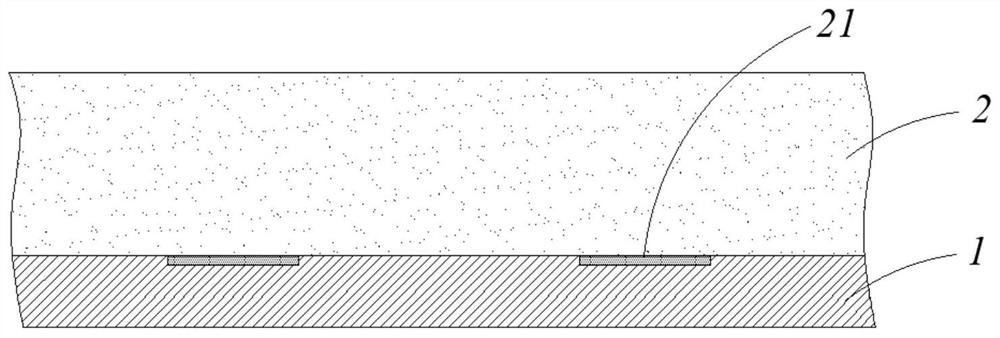

[0048] S11: If figure 2 As shown, a wafer 2 and a substrate 1 provided with bonding pads 21 are provided, and the wafer 2 is covered on the substrate 1 with the bonding pads 21 facing the direction of the substrate 1 .

[0049] The substrate 1 can be a material with a certain thickness and hardness such as bare silicon chip, glass, resin, etc., or it can be a thick adhesive tape. Different materials for the substrate 1 can be selected according to different chip functions. An adhesive layer is coated on the substrate 1 for bonding and fixing it with the wafer 2 .

[0050] A plurality of chip units arranged in an array are formed on the wafer 2, and a passivation layer is provided on one side of the wafer 2, and a plurality of welding pads 21 are distributed inside the passivation layer, serving as the...

Embodiment 2

[0070] The manufacturing method of the 2-level TSV packaging structure on the wafer in Example 2 is basically similar to that of Example 1, and the difference from Example 1 lies in:

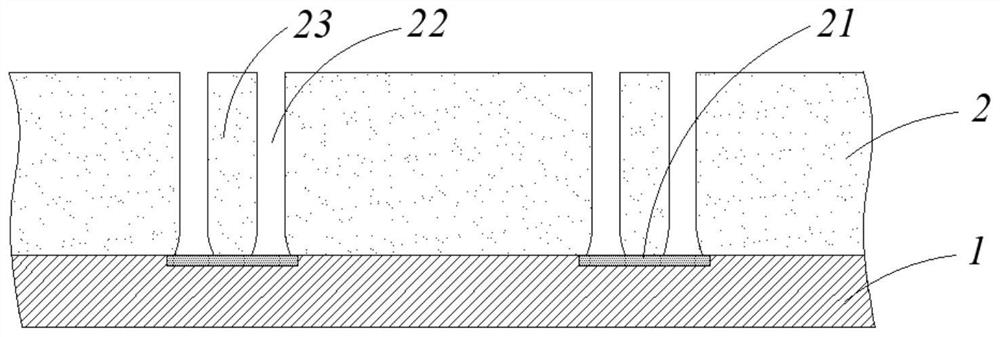

[0071] like Figure 7a As shown, in step S4, only the dry film 3a on the middle part of the upper surface of the residual silicon 23 is photolithographically exposed to expose the middle part of the residual silicon 23, and the dry film 3a on the upper surface of the outer ring of the remaining silicon 23 is not etched.

[0072] like Figure 7b As shown, a through hole 24 exposing the pad 21 is formed in the middle part of the etched residual silicon 23, and an annular silicon layer 231 is formed on the inner wall surface of the dry film 3a in the outer part of the unetched residual silicon 23. like Figure 8 As shown, after the subsequent formation of the metal layer 4, the ring-shaped silicon layer 231 is sandwiched between the insulating layer 3 and the metal layer 4, which can be used as a...

Embodiment 3

[0074] The manufacturing method of wafer 2-level through-silicon via packaging structure in Example 3 is directly etched to form a through-hole, and then directly laminates the dry film 3a and the sputtered metal layer 4, which specifically includes steps:

[0075] S21 : providing a wafer 2 and a substrate 1 provided with bonding pads 21 , and covering the wafer 2 on the substrate 1 with the bonding pads 21 facing the substrate 1 .

[0076] S22 : forming a through hole on the wafer 2 , and making at least a partial overlap between the outside of the through hole and the bonding pad 21 .

[0077] S23: Laminating a layer of dry film 3a on the surface of the wafer 2, and laminating the dry film 3a into the through hole so that it completely fills the through hole.

[0078] S24 : removing part of the insulating layer 3 located in the through hole to form a through hole 24 exposing the pad 21 .

[0079] S25 : Depositing a seed layer 41 on the surface of the insulating layer 3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com