Dehydrogenation catalyst as well as preparation method and application thereof

A technology of dehydrogenation catalyst and auxiliary agent, applied in the field of alkane dehydrogenation, can solve the problems of catalyst coke deposition, deactivation, expensive catalyst, etc., and achieve the effects of improving stability and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

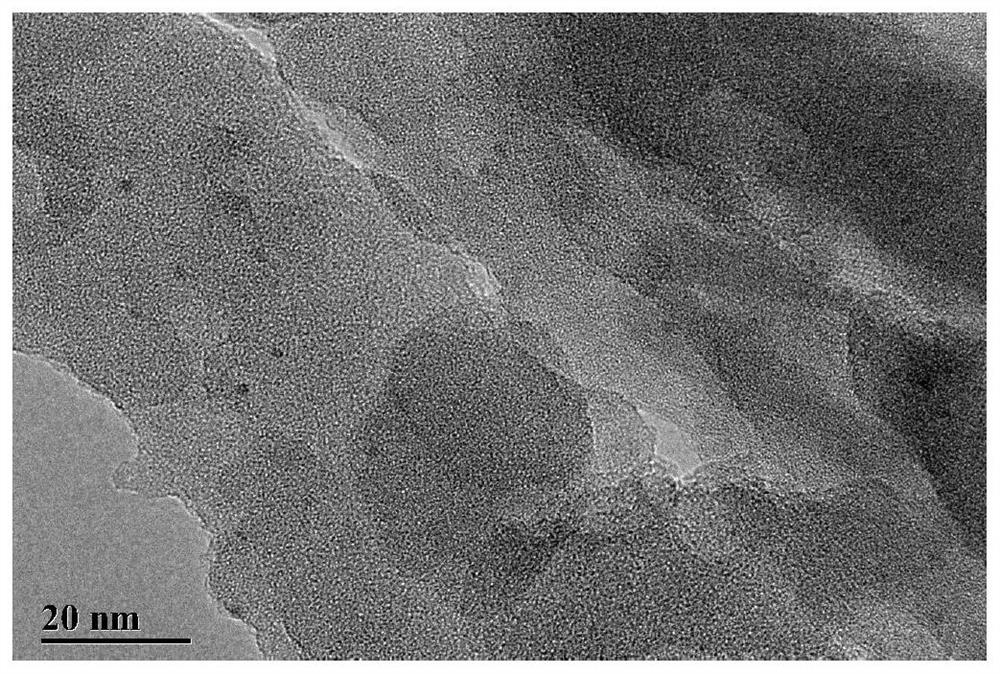

Image

Examples

preparation example Construction

[0031] The present invention provides the preparation method of dehydrogenation catalyst described in above-mentioned scheme, comprises the following steps:

[0032] Na-type ZSM-5 molecular sieves are impregnated into a solution containing a Pt precursor, dried and calcined to obtain a dehydrogenation catalyst;

[0033] The mass of Pt in the solution corresponds to the content of noble metal Pt in the dehydrogenation catalyst.

[0034] In the present invention, the Na-type ZSM-5 molecular sieve is preferably obtained by self-preparation. The present invention has no special requirements for the preparation method of the Na-type ZSM-5 molecular sieve, and the Na-type ZSM-5 molecular sieve well-known in the art is used. method. In an embodiment of the present invention, the preparation method of the Na-type ZSM-5 molecular sieve preferably includes: adding sodium hydroxide, aluminum nitrate, tetrapropylammonium hydroxide, ethyl orthosilicate and water into the crystallization tan...

Embodiment 1~3

[0042] The preparation method of Na type ZSM-5 molecular sieve used in embodiment 1~3 is as follows:

[0043] 1.54g sodium hydroxide, 0.24g aluminum nitrate, 23.42g tetrapropylammonium hydroxide, 40g tetraethyl orthosilicate and 86.2gh 2 Add O into the crystallization kettle, then stir at room temperature for 20min, crystallize in a homogeneous reactor at 170°C for 2 days, filter, dry overnight at 80°C, and roast in a muffle furnace at 580°C for 12h to synthesize Si / Al Na type ZSM-5 molecular sieve with a ratio of 200.

Embodiment 4~6

[0044] The preparation method of Na type ZSM-5 molecular sieve used in embodiment 4~6 is as follows:

[0045] Add 1.54g of sodium hydroxide, 0.48g of aluminum nitrate, 23.42g of tetrapropylammonium hydroxide, 40g of tetraethyl orthosilicate and 86.2g of water into the crystallization tank and stir at room temperature for 20min. After internal crystallization for 2 days, filter, dry overnight at 80°C, and calcine in a muffle furnace at 570°C for 14 hours, the Na-type ZSM-5 molecular sieve with a Si / Al ratio of 100 can be synthesized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com