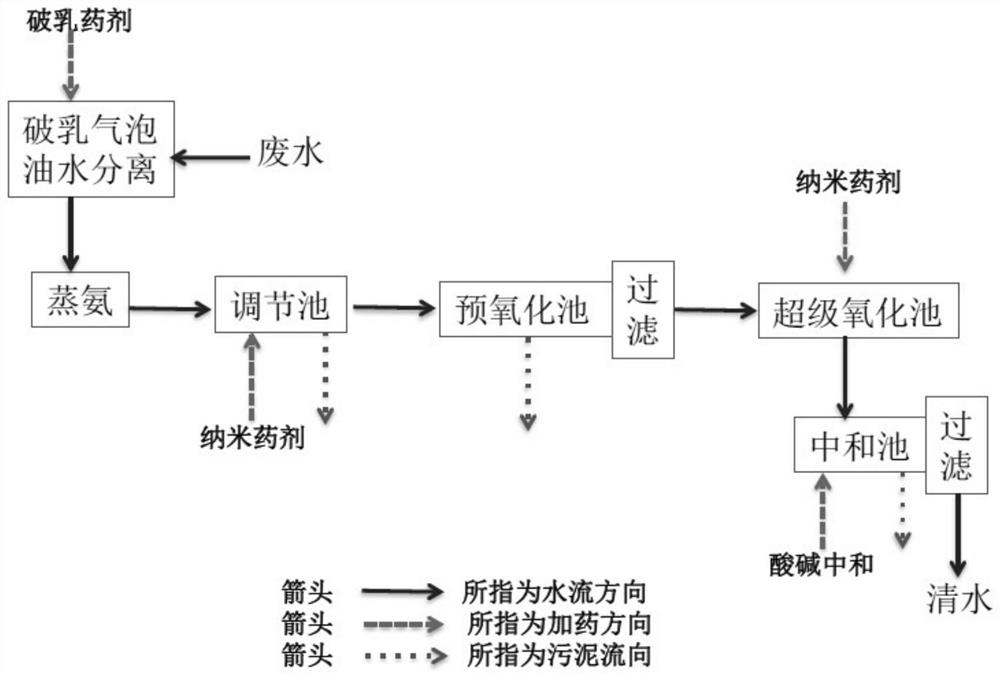

Heavily-polluted semi-coke wastewater treatment process

A semi-coke wastewater and treatment process technology, applied in water/sewage treatment, heating water/sewage treatment, light water/sewage treatment, etc., can solve the problems of high cost, high chloride ion concentration, and large amount of sludge, and achieve Reduced operating costs and reduced COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

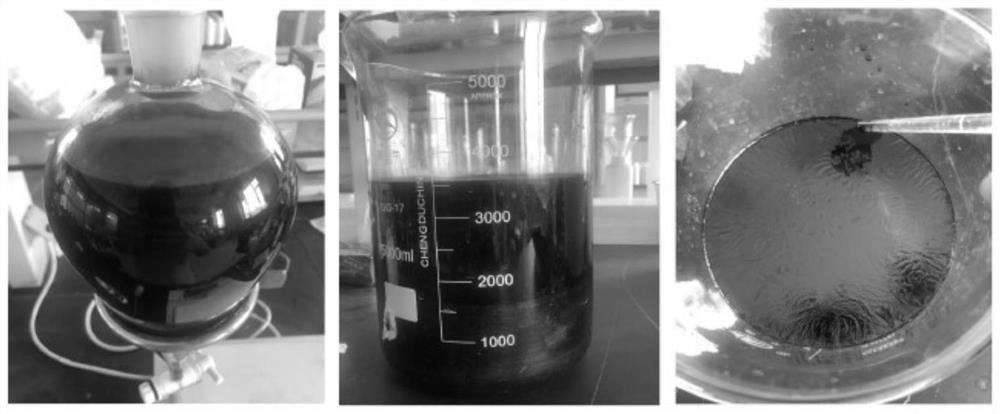

[0072] S1: Pretreat 1L of wastewater, remove oil and filter the wastewater, then add 0.4L of demulsifier to the wastewater, and keep stirring; the demulsifier is an alkyl chain of C 8 h 17 Compound A;

[0073] S2: Distill the wastewater treated in S1, the temperature inside the ammonia distillation tower is 100°C, then adjust the pH of the wastewater to neutral, and add 0.5g of tricobalt tetroxide;

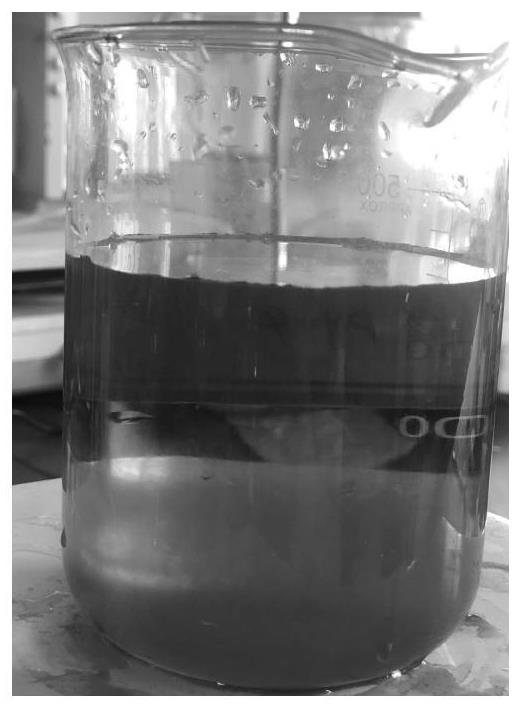

[0074] S3: Pre-oxidize the wastewater under light conditions, filter the wastewater, and then perform super oxidation under light conditions, and add 0.5g of tricobalt tetroxide and 0.25L of 98% hydrogen peroxide solution;

[0075] S4: neutralize the waste water, and then filter it.

[0076] The situation of comparative example 1 and comparative example 4 and the sediment of embodiment 1, and the situation after demulsification are shown in table 1, and it can be seen from table 1 that in embodiment 1.

[0077] Table 1: Comparison of Comparative Example 1-Comparative Example 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com