Method and a system for separating hydrogen obtained by reforming

A separation method and separator technology, applied in hydrogen separation, chemical instruments and methods, hydrogen/synthesis gas production, etc., can solve the problem of increasing pressure drop between stages of reforming hydrogen supercharger, increasing cooling capacity and heat exchange recovery, public utility Problems such as increased project consumption, to achieve the effect of low outlet pressure, low cooling load, and reduced cooling load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

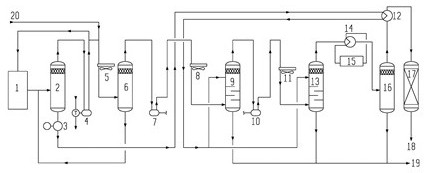

[0030] Such as figure 1As shown, a reforming hydrogen separation system includes a reaction product separator 2, a liquid separation tank 6 at the inlet of a reforming hydrogen booster, a first-stage recontacting tower 9, a second-stage recontacting tower 13, and a reforming hydrogen separator Tank 16 and reforming hydrogen dechlorination tank 17, the reaction product separator 2 is provided with the product inlet of the whole reaction system 1, the top outlet of the reaction product separator 2 is connected to the reforming cycle hydrogen compressor 4, and the reforming cycle hydrogen compressor 4 outlets are respectively connected to the top inlet of the reforming reaction system 1 and the liquid separation tank 6 at the inlet of the reforming hydrogen booster, and the bottom outlet of the reaction product separator 2 is respectively connected to the upper part of the first-stage recontact tower 9 and the second stage through the reforming hydrogen heat exchanger 12. The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com