Phenol adsorption enhanced reforming hydrogen production method

A technology for reforming hydrogen and phenol, which is applied in the energy field to achieve the effects of good stability, high activity, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

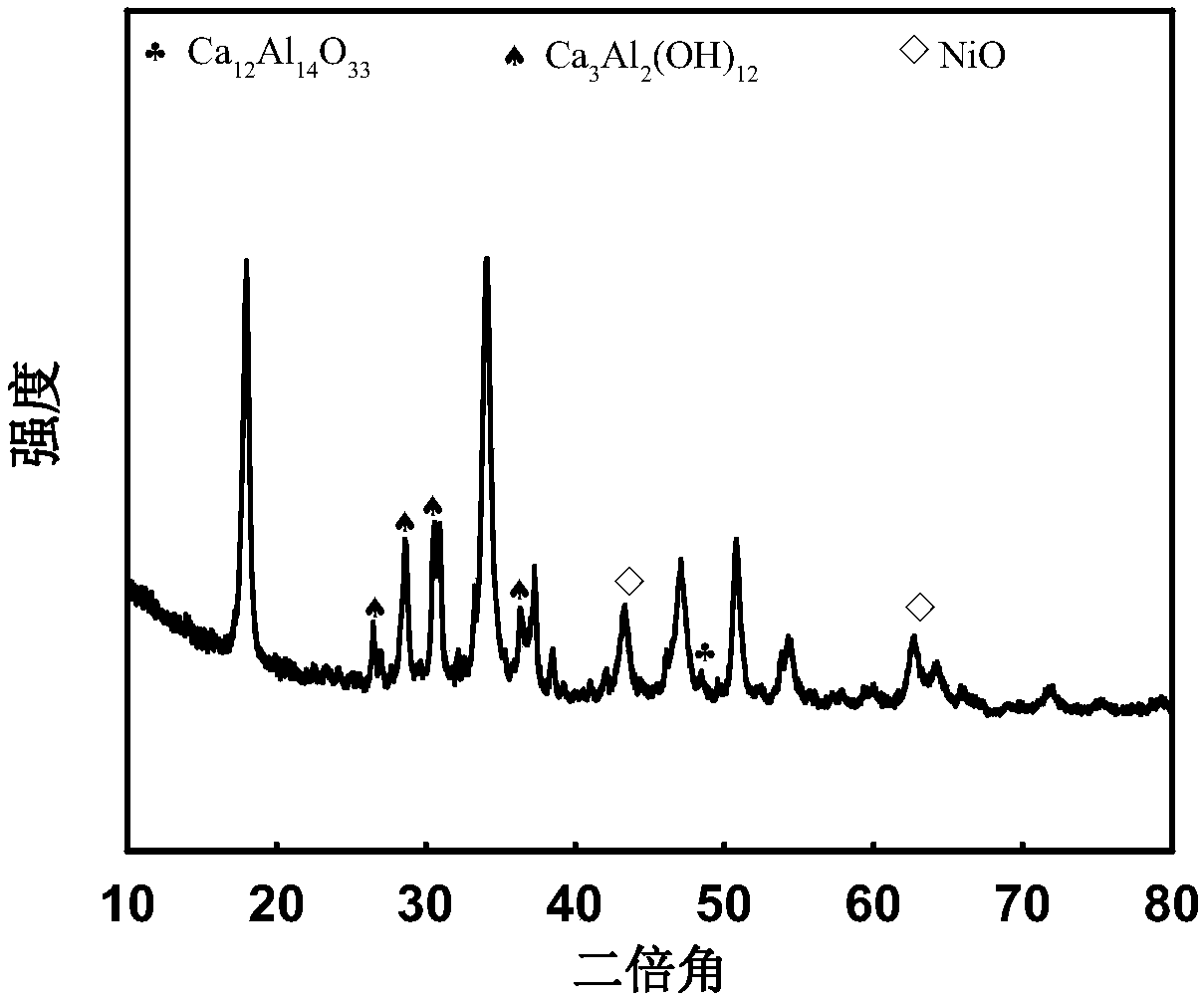

[0027] Weigh 0.0043mol of nickel nitrate, 0.064mol of the calcium salt in Table 1 and 0.023mol of the aluminum salt in Table 1, dissolve them in 50ml of water, dry at 120°C, and roast the obtained product in a muffle furnace at 800°C for 4h to obtain Ni -Ca-Al-O catalyst, Ni-Ca-Al-O catalyst packed in a fixed bed, argon as carrier gas, 1.296h -1 A phenol aqueous solution with a concentration of 0.0797 g / ml was introduced at a weight hourly space velocity of 0.0797 g / ml, and the reaction temperature was 550° C., and the purity of hydrogen in the product after 15 minutes of reaction was shown in Table 1 below. The X-ray diffraction figure, TEM figure of embodiment 1 gained Ni-Ca-Al-O catalyst are as follows figure 1 , figure 2 shown.

[0028] Table 1

[0029] Example

Embodiment 6-11

[0031] Take by weighing 0.0043mol nickel nitrate, 0.064mol calcium nitrate and 0.023mol aluminum nitrate, dissolve in 50ml water, dry at 120°C, and the product obtained is roasted under the conditions of Table 2 to obtain Ni-Ca-Al-O catalyst, in a fixed bed Fill Ni-Ca-Al-O catalyst in the medium, argon as carrier gas, take 1.296h -1 A phenol aqueous solution with a concentration of 0.0797 g / ml was introduced at a weight hourly space velocity of 0.0797 g / ml, the reaction temperature was 550° C., and the purity of hydrogen in the product after 15 minutes of reaction was shown in Table 2 below.

[0032] Table 2

[0033] Example

Embodiment 12-15

[0035] Weigh the calcium nitrate, aluminum nitrate and nickel nitrate shown in Table 3, dissolve them in 50ml of water, dry at 120°C, and roast the obtained product in a muffle furnace at 800°C for 4h to obtain Ni-Ca-Al-O catalyst. In the phenol adsorption enhanced steam reforming reaction, the Ni-Ca-Al-O catalyst was filled in the fixed-bed reactor, and argon was used as the carrier gas, with 1.296h -1 A phenol aqueous solution with a concentration of 0.0797 g / ml was introduced at a weight hourly space velocity of 0.0797 g / ml, and the reaction temperature was 550° C. After 15 minutes of reaction, the purity of hydrogen in the product and the conversion rate of phenol were shown in Table 3 below.

[0036] table 3

[0037] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com