Device and method for separating hydrogen chloride from tail gas of fumed silica production

A technology of gas-phase silica and hydrogen chloride, which is applied in the direction of separation methods, chemical instruments and methods, chlorine/hydrogen chloride, etc., can solve problems such as low concentration of hydrochloric acid, low external sales price, and influence on the normal operation of gas-phase silica devices, and achieve The effect of high added value and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

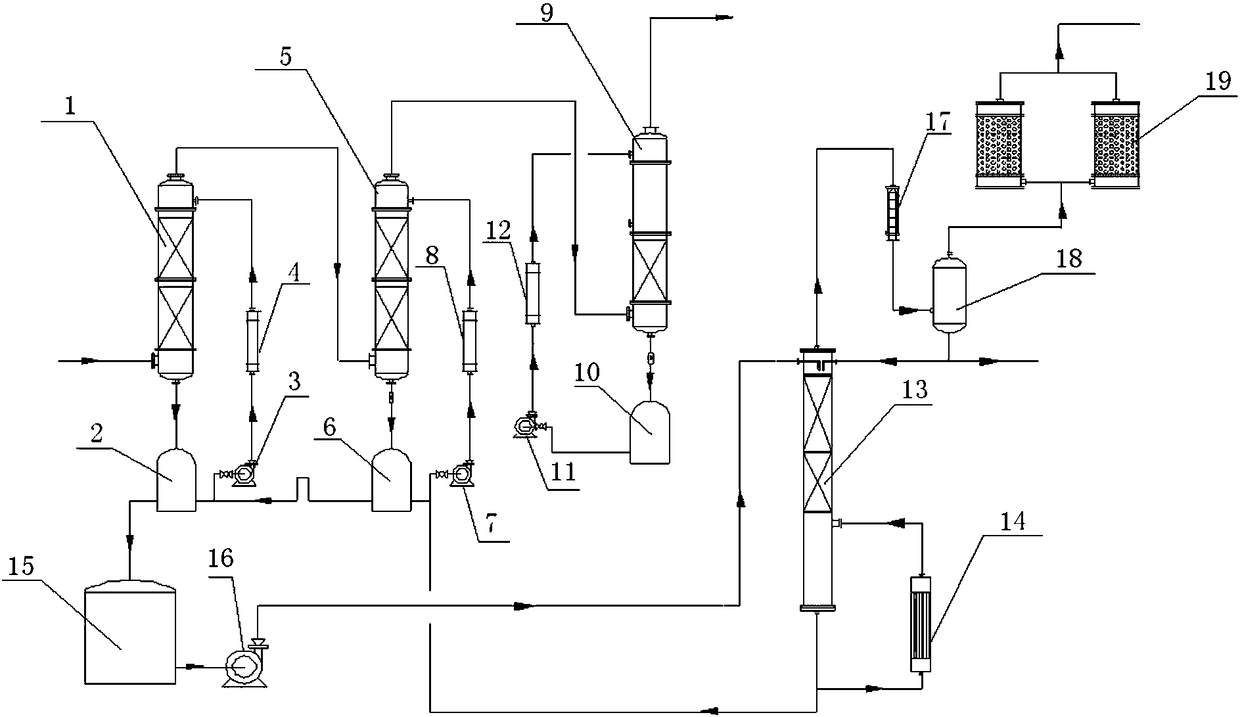

[0038] Such as figure 1 As shown, this embodiment provides a device for separating hydrogen chloride from exhaust gas from gas-phase white carbon black production, including:

[0039] The concentrated acid absorption tower 1 is used to use the first absorption liquid concentrated hydrochloric acid to rinse the gas-phase white carbon black production tail gas passed into the concentrated acid absorption tower 1 to obtain the first tail gas that has been treated by the concentrated acid absorption tower 1; Gas-phase white carbon black production tail gas includes: hydrogen chloride, chlorine, nitrogen, oxygen;

[0040] It should be noted that the device for separating hydrogen chloride from the gas-phase white carbon black production tail gas in this embodiment also includes: a concentrated acid buffer tank 2, which is connected to the bottom of the concentrated acid absorption tower 1, and the concentrated acid buffer tank 2 is used for buffering The bottom liquid of concentrated a...

Embodiment 2

[0057] Such as figure 1 As shown, this embodiment provides a method for separating hydrogen chloride from gas-phase white carbon black production tail gas using the device in embodiment 1, which includes the following steps:

[0058] (1) Pass the gas-phase white carbon black production tail gas containing hydrogen chloride, chlorine, nitrogen, and oxygen to the bottom of the concentrated acid absorption tower 1, and the first absorption liquid concentrated hydrochloric acid with a mass percentage concentration of 24-27% in the concentrated acid absorption tower 1. Gas-liquid contact in the packing layer, the temperature is controlled at 30~45℃, the flow rate of the first absorption liquid concentrated hydrochloric acid is controlled at 6~10m 3 / h, the first tail gas processed by the concentrated acid absorption tower 1 is obtained. After the first absorption liquid concentrated hydrochloric acid absorbs part of the hydrogen chloride in the gas-phase white carbon black production t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com