Single-photon detector, manufacturing method thereof and single-photon detector array

A single photon detector and manufacturing method technology, applied in the direction of electric solid-state devices, semiconductor devices, final product manufacturing, etc., can solve problems such as edge breakdown, reduce the edge electric field, suppress the edge breakdown problem, and reduce complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

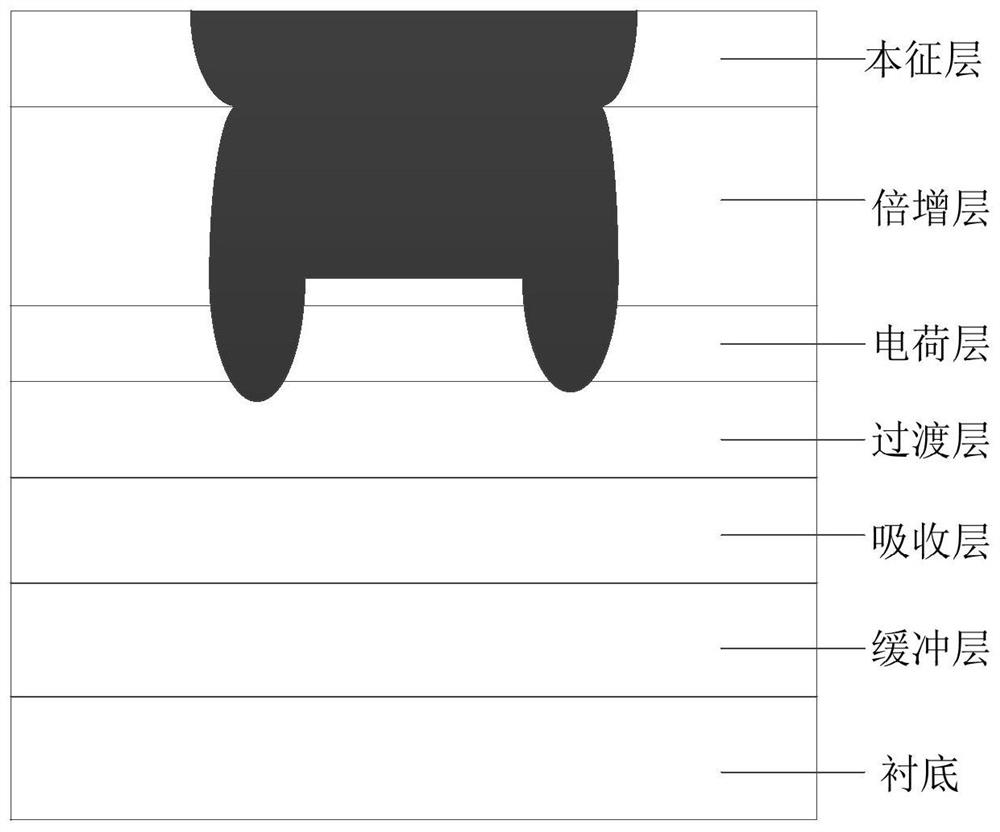

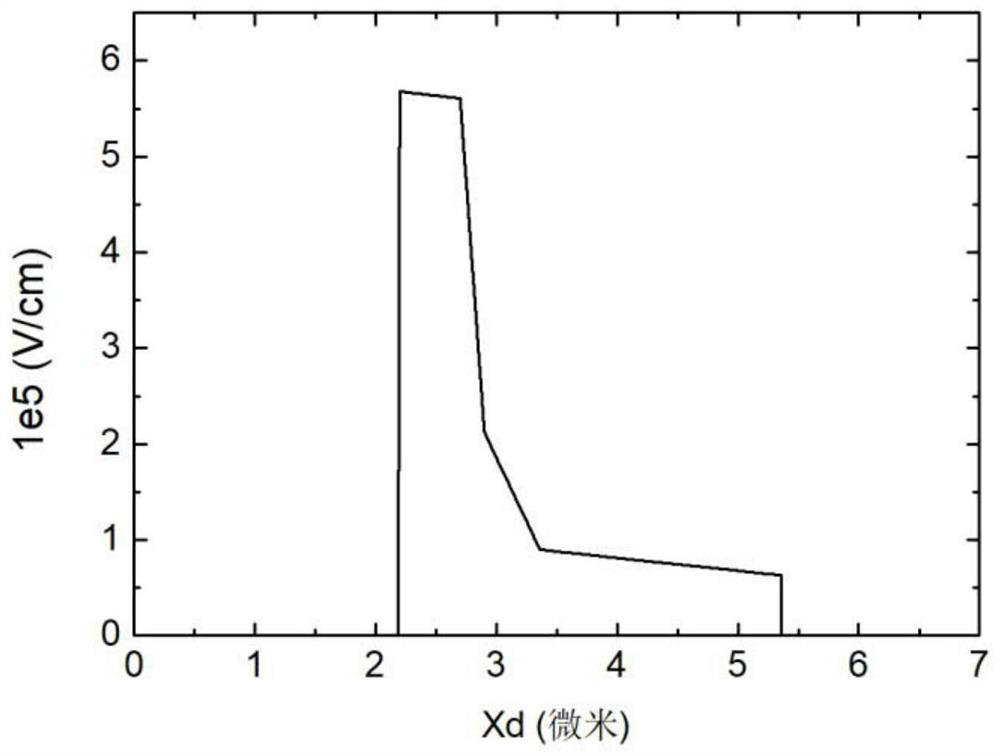

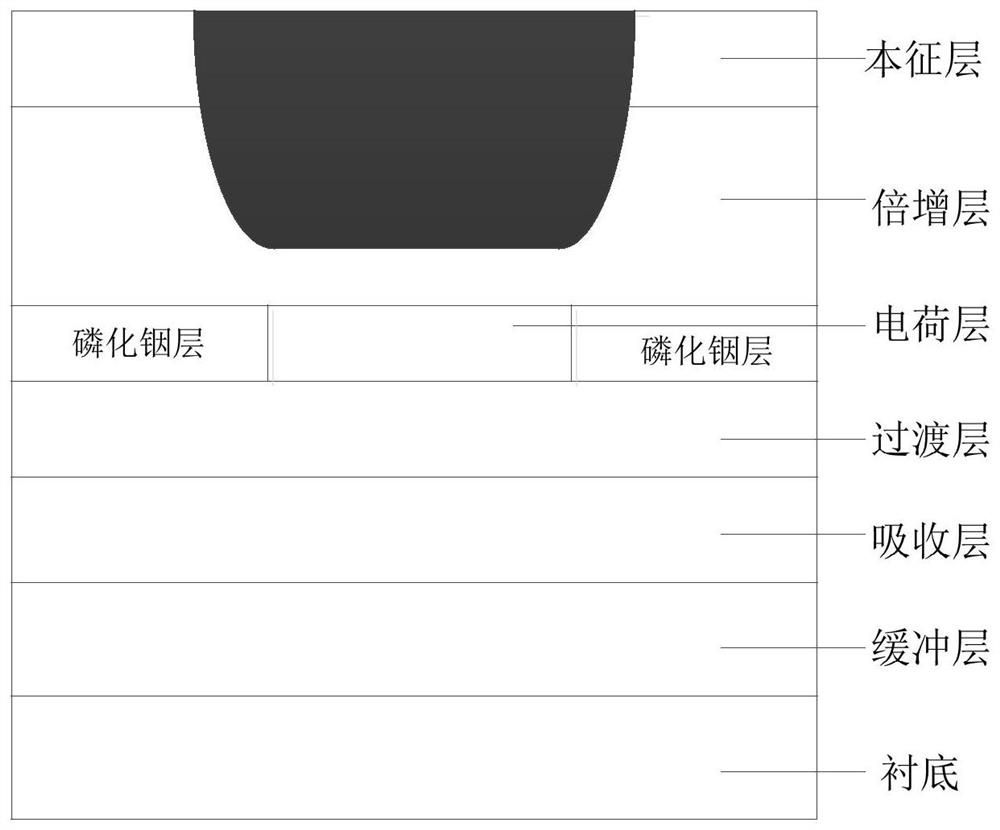

[0053] Common single photon detectors in the prior art mainly include two types. The main manufacturing process of the first method includes sequentially forming a buffer layer, an absorption layer, a transition layer, a charge layer, a multiplication layer and an intrinsic layer on a substrate. Then two diffusion processes are used to form diffusion regions in the intrinsic layer, multiplication layer and charge layer, and the formed structure is as follows figure 1 shown in . The electric field distribution diagram of the structure formed in this way is shown in figure 2 as shown in the figure 2 As shown, under the action of the charge layer, the electric field is the strongest in the multiplication layer, and the absorption layer is relatively weak, which ensures that the multiplication layer can produce collision ionization and the absorption layer does not ionize, but it can ensure that the carriers migrate at the saturation speed and increase the APD. response speed....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com