Positive pole piece for solid-state battery, preparation method and application thereof

A technology for solid-state batteries and positive pole pieces, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problem of affecting the stability and uniformity of the coating layer, affecting the battery rate and cycle performance, and the difficulty of grasping the thickness of the coating layer To achieve high flexibility and practical value, improve rate performance and cycle performance, and reduce transmission impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

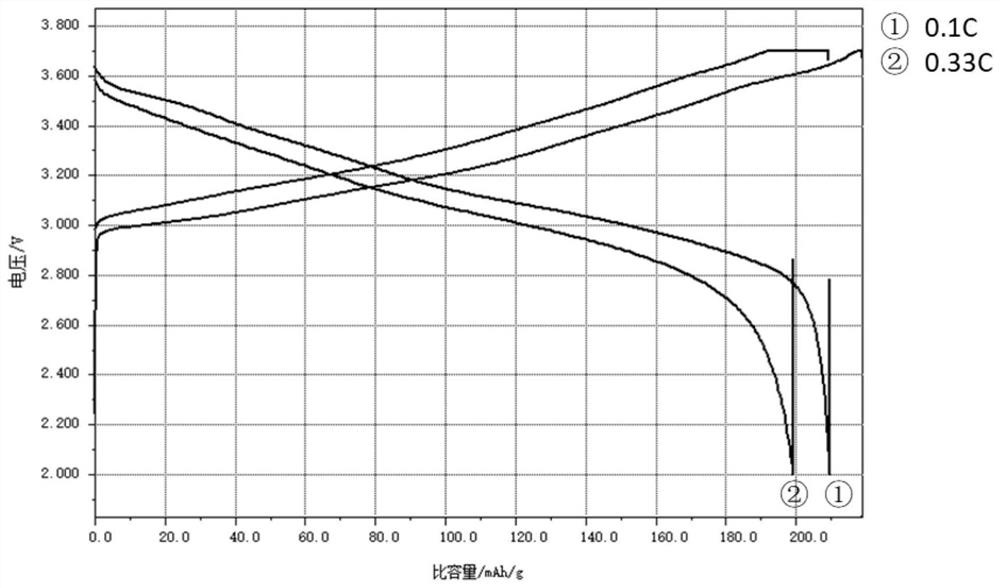

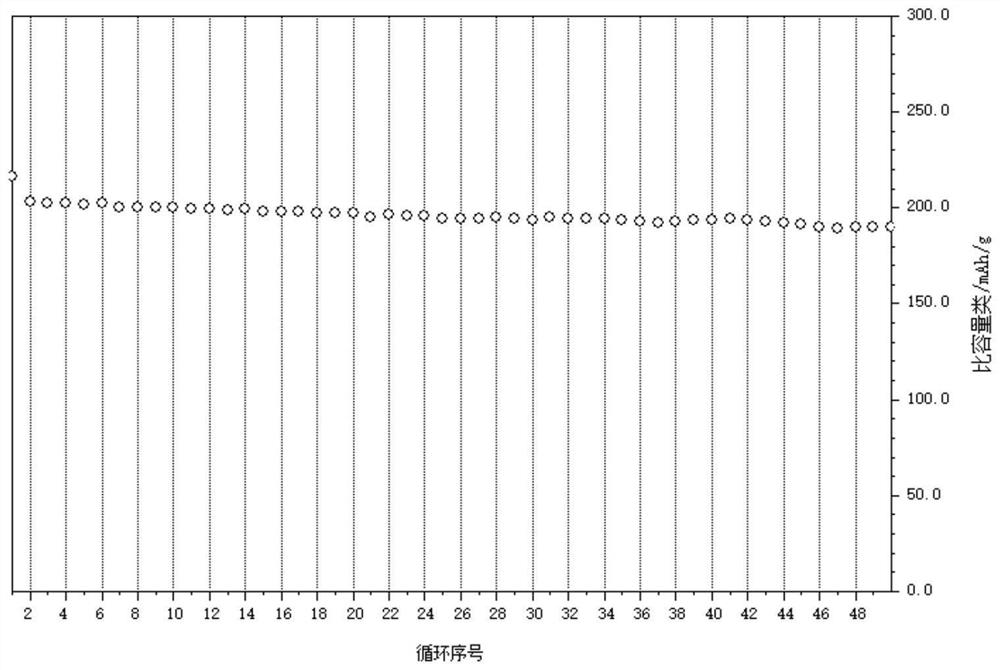

Embodiment 1

[0060] This embodiment provides a method for preparing a positive electrode sheet for a solid-state battery, and the preparation method is as follows:

[0061] (1) The sulfide solid electrolyte Li 6 P.S. 5 Cl is dissolved in absolute ethanol to obtain a sulfide solid electrolyte solution, and the viscosity of the solvent is controlled at 10cp;

[0062] (2) Atomize the sulfide solid electrolyte solution in step (1) by spraying method to make it adhere to the positive electrode active material LiNi 0.9 co 0.05 mn 0.05 o 2 At the same time, the solvent is dried to obtain a uniform and thin sulfide solid electrolyte coating layer on the surface of the positive electrode active material; the thickness of the corresponding coating layer is 50nm;

[0063] (3) Put the positive electrode active material coated with the sulfide solid electrolyte and the conductive carbon prepared above into the mixer, the mass ratio of the conductive carbon to the above-mentioned substance is 2:98,...

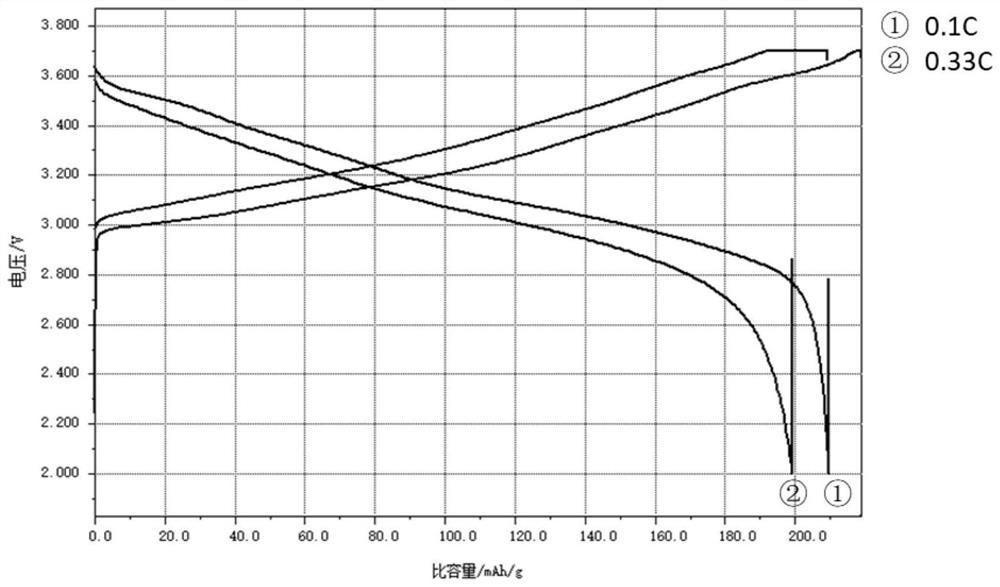

Embodiment 2

[0066] This embodiment provides a method for preparing a positive electrode sheet for a solid-state battery, and the preparation method is as follows:

[0067] (1) The halide solid electrolyte Li 3 InCl 6 Dissolve in pure water to obtain a halide solid electrolyte solution, and the viscosity of the solvent is controlled at 12cp;

[0068] (2) Atomize the halide solid electrolyte solution in step (1) by spraying method to make it adhere to the positive electrode active material LiNi 0.8 co 0.1 mn 0.1 o 2 At the same time, the solvent is dried to obtain a uniform and thin halide solid electrolyte coating layer on the surface of the positive electrode active material; the thickness of the corresponding coating layer is 100nm;

[0069] (3) Put the positive electrode active material and conductive carbon coated with the sulfide solid electrolyte prepared above into the mixer, the mass ratio of the conductive carbon to the above-mentioned substance is 3:97, and stir for 50min at...

Embodiment 3

[0071] The difference between this embodiment and Embodiment 1 is that the binder in step (3) of this embodiment is polyvinylidene fluoride.

[0072] All the other preparation methods and parameters are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com