High-conversion-rate battery substrate preparation method for new energy

A battery substrate, a technology with high conversion rate, applied in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of low conversion rate of ceramic battery substrates, high surface roughness of ceramic substrates, and low uniformity of deposited layers, etc. problems, to achieve the effect of improving conversion efficiency, reducing surface roughness, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

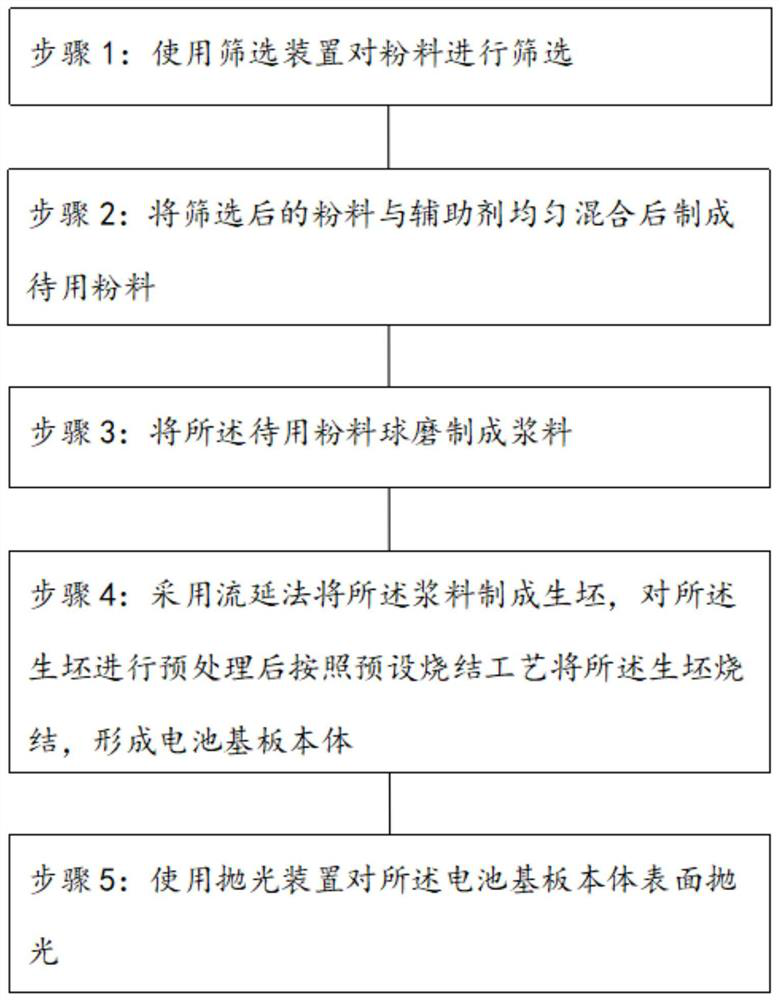

[0068] The embodiment of the present invention provides a method for preparing a battery substrate with a high conversion rate for new energy, such as Figure 1-Figure 7 shown, including the following steps:

[0069] Step 1: Use a screening device to screen the powder;

[0070] Step 2: Evenly mix the screened powder and auxiliary agent to make ready-to-use powder;

[0071] Step 3: ball milling the powder to be used to make a slurry;

[0072] Step 4: Making the slurry into a green body by tape casting, pretreating the green body and sintering the green body according to a preset sintering process to form a battery substrate body;

[0073] Step 5: Using a polishing device to polish the surface of the battery substrate body.

[0074] The working principle and beneficial effects of the above-mentioned technical scheme are as follows: firstly, use a screening device to screen the powder, then uniformly mix the screened powder with an auxiliary agent to make a ready-to-use powder...

Embodiment 2

[0076] On the basis of above-mentioned embodiment 1, in described step 1, described powder is zirconia powder;

[0077] In the step 1, the screening device is used to control the particle size and purity of the powder;

[0078] In the step 2, the auxiliary agent includes a preset ratio of composite sintering aids, dispersants, plasticizers, and binders;

[0079] In the step 3, using an organic solvent to carry out ball milling to the powder to be used;

[0080] In the step 3, after making the slurry, vacuum defoaming and curing the slurry;

[0081] In said step 4, said preprocessing includes the following steps:

[0082] Step 41: First use a punching machine to cut the green body into pieces, and send the cut green body to an isostatic press for isostatic pressing. The pressure of the isostatic pressing is 10-14 MPa, The temperature is 80-90°C;

[0083] Step 42: Perform electric powder coating on the green body;

[0084] Step 43: Polishing the ceramic sheet, the surface r...

Embodiment 3

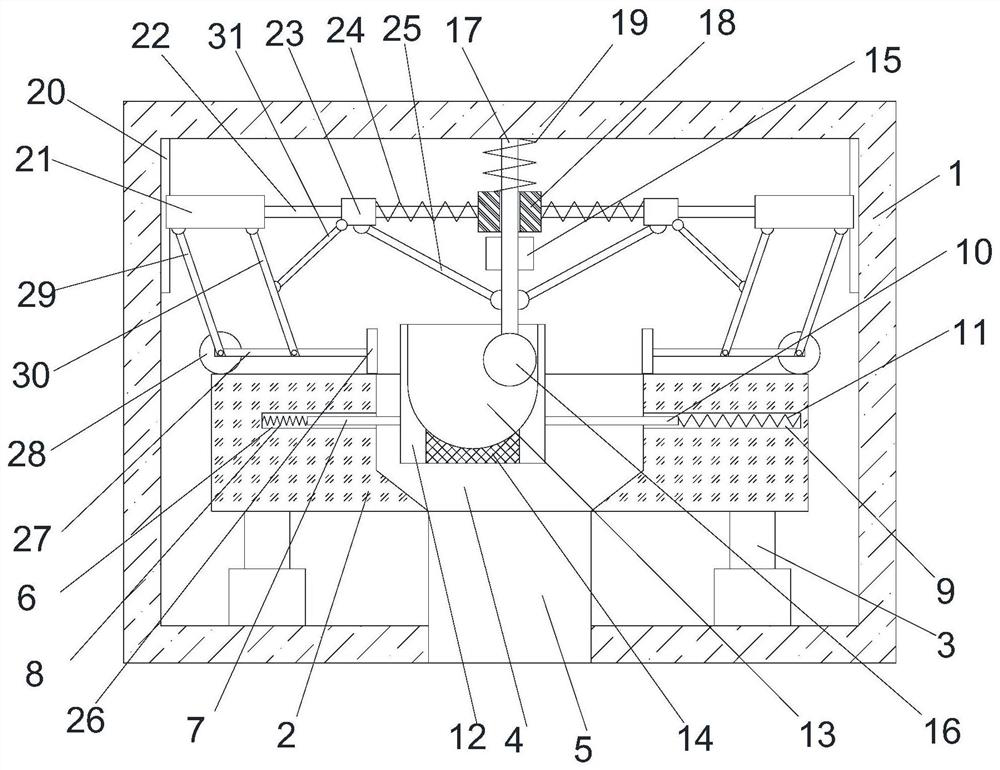

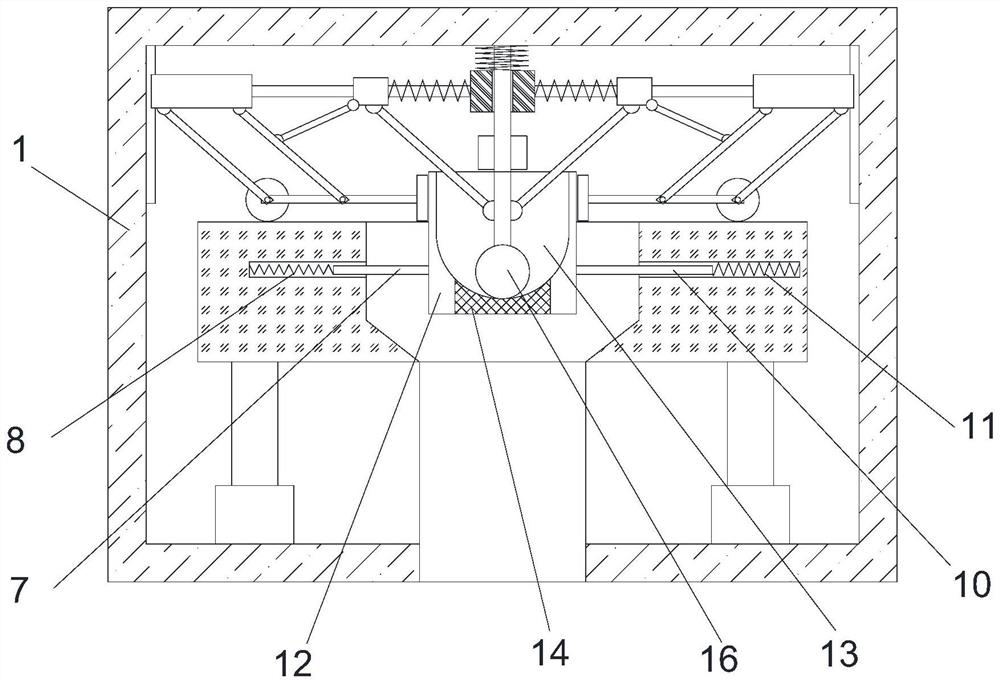

[0088] On the basis of embodiment 1 or 2, such as figure 2 , image 3 As shown, the screening device includes:

[0089] Screening box 1, a mobile platform 2 is arranged in the screening box 1, and the lower surface of the mobile platform 2 is symmetrically provided with an electric lifting column 3, and one end of the electric lifting column 3 is fixedly connected with the inner wall of the bottom of the screening box 1, and the The other end of the electric lifting column 3 is fixedly connected to the lower surface of the mobile platform 2;

[0090] The first through hole 4, the first through hole 4 is arranged at the center position of the mobile platform 2, the first through hole 4 runs through the upper and lower surfaces of the mobile platform 2, and the first through hole 4 is arranged near the lower end It is rounded;

[0091] The first pipeline 5, the first pipeline 5 is arranged at the lower end of the first through hole 4, the upper end of the first pipeline 5 co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com