Compost for chaenomeles speciosa

A composting and fragrant wood technology, applied in the direction of application, nitrogen fertilizer, phosphate fertilizer, etc., can solve the problems of low decay, slow decay of compost materials, and low nutrients in straw, and achieve the effect of high decay, simple production method, and rich nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

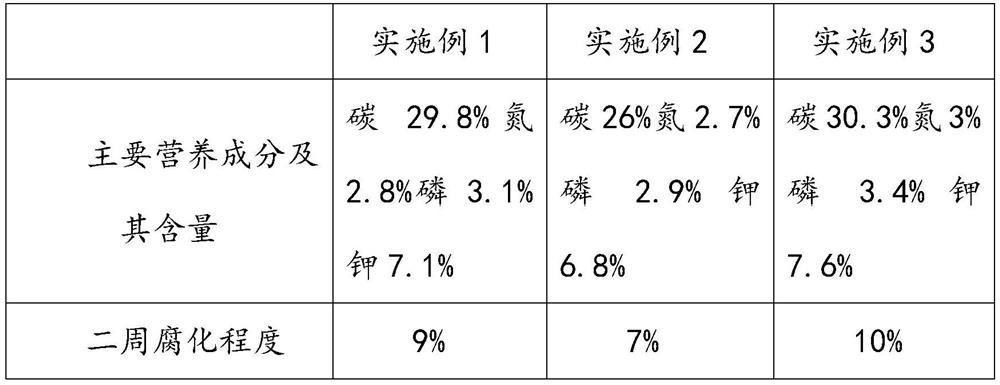

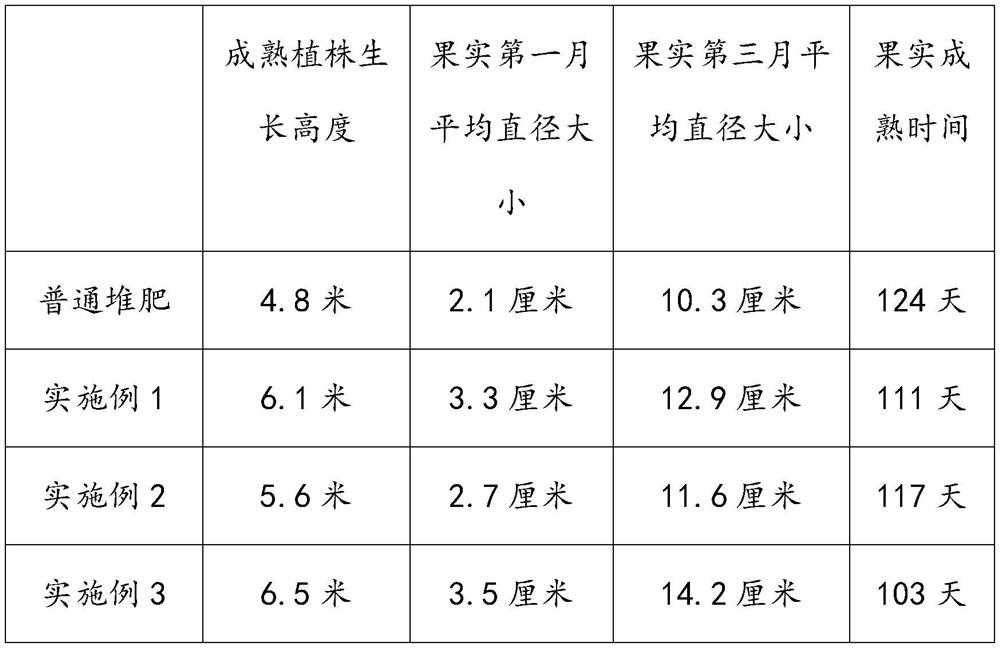

Embodiment 1

[0025] A compost for fragrant papaya, comprising the following raw materials in parts by weight: basic raw material 42, decay-promoting raw material 17, nitrogen-maintaining raw material 12 and borax 5.

[0026] Wherein, the basic raw materials include 47 bran, 12 corn stalks, 12 mulberry leaves, 12 banana peels, and 7 sea wind rattan by weight parts.

[0027] Wherein said rotting-promoting raw material, by weight, comprises 25 pigpen manures, 7 rotting-promoting bacterial seed powders.

[0028] Wherein, the putrefaction-promoting bacteria seed powder includes 7% Bacillus subtilis and 7% plantaractobacillus by weight percentage.

[0029] Wherein said nitrogen-preserving raw material, by weight, 9 calcium phosphate, 12 ammonium persulfate, 14 monoammonium phosphate.

[0030] The preparation method of fragrant papaya compost comprises the following steps:

[0031] (1) Place the basic raw material in a pulverizer and pulverize it to a length of no more than 2 cm;

[0032] (2) ...

Embodiment 2

[0040] A compost for fragrant papaya, comprising the following raw materials in parts by weight: 40 basic raw materials, 10 rot-promoting raw materials, 10 nitrogen-maintaining raw materials and 1 borax.

[0041] Wherein, the basic raw materials include 45 bran, 10 corn stalk, 10 mulberry leaf, 10 banana peel and 5 sea wind rattan by weight parts.

[0042] Wherein said rot-promoting raw material comprises 20 pigsty excrement and 5 rotting-promoting bacterial seed powders by weight.

[0043] Wherein said rot-promoting bacteria powder, by weight percentage, 5% Bacillus subtilis, 5% Lactobacillus plantarum.

[0044] Wherein said nitrogen-preserving raw material, by weight, 7 calcium phosphate, 10 ammonium persulfate, 13 monoammonium phosphate.

[0045] The preparation method of fragrant papaya compost comprises the following steps:

[0046] (1) Place the basic raw material in a pulverizer and pulverize it to a length of no more than 2 cm;

[0047] (2) Dig out the ventilation d...

Embodiment 3

[0055] A compost for fragrant papaya, comprising the following raw materials in parts by weight: 45 basic raw materials, 25 rot-promoting raw materials, 15 nitrogen-maintaining raw materials and 10 borax.

[0056] Wherein the basic raw materials include 50 bran, 15 corn stalks, 15 mulberry leaves, 15 banana peels and 10 sea wind rattan by weight parts.

[0057] Wherein said rotting-promoting raw material, by weight, comprises 30 pigpen manures, 10 rotting-promoting bacteria seed powder.

[0058] Wherein, the putrefaction-promoting bacteria seed powder includes 10% Bacillus subtilis and 10% Lactobacillus plantarum by weight percentage.

[0059] Wherein said nitrogen-preserving raw material, by weight, 11 calcium phosphate, 15 ammonium persulfate, 15 monoammonium phosphate.

[0060] The preparation method of fragrant papaya compost comprises the following steps:

[0061] (1) Place the basic raw material in a pulverizer and pulverize it to a length of no more than 2 cm;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com