Process for continuous activation production of active humic acid organic fertilizer

A technology of active humic acid and process method, which is applied in the field of continuous activation production of active humic acid organic fertilizer, can solve problems such as unfavorable healthy growth of crops, insufficient transformation of organic matter, inability to kill harmful bacteria and Ascaris Escherichia coli, and achieve a significant ecological Environmental benefits, reducing heavy metal pollution, and promoting healthy development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

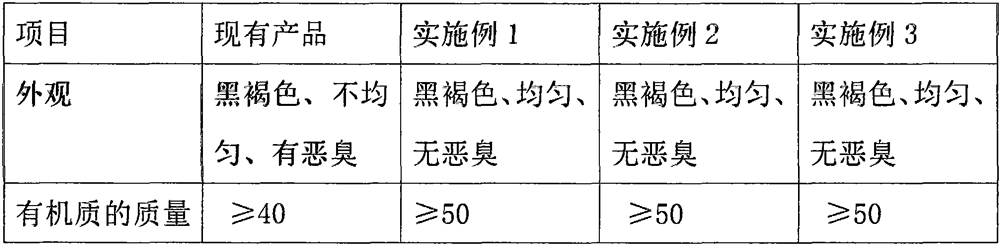

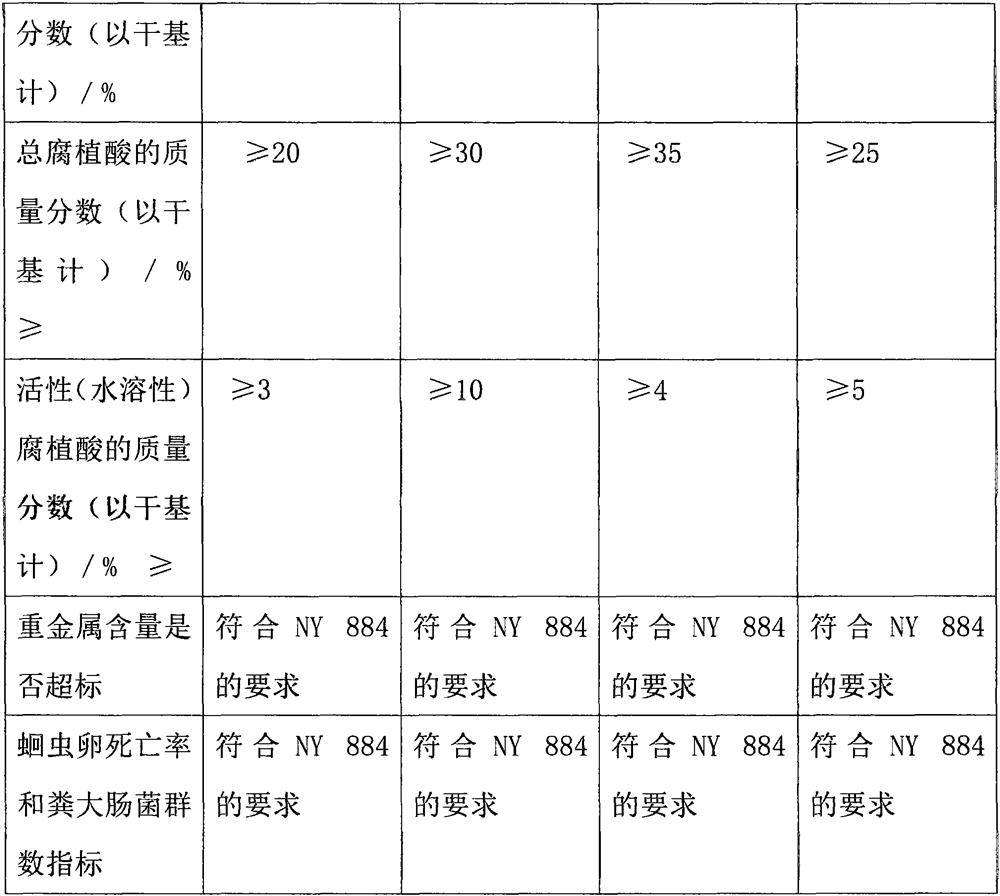

Examples

Embodiment 1

[0023] The technical method for the continuous activation production of active humic acid organic fertilizer comprises the following steps:

[0024] S1. The humic acid lignite is measured by the belt conveyor and then enters the crusher, and the crusher is used for primary crushing. After the crusher comes out, it passes through the crushing belt and enters the drum screen for sieving. The qualified particle size enters the mixing mixer 1, and the unqualified particle size , transported by the return belt to the primary crusher for crushing;

[0025] S2. Pour the nitrogen, phosphorus and potassium materials into the feeding hopper. After being measured by the feeding belt, they respectively enter the belt at the entrance of the trommel sieve. After mixing, they enter the trommel sieve, and carry out uniform mixing in the trommel sieve. The uniform nitrogen, phosphorus and potassium materials are put into the mixer 1;

[0026] S3. Dry the organic matter such as livestock and p...

Embodiment 2

[0032] The technical method for the continuous activation production of active humic acid organic fertilizer comprises the following steps:

[0033] S1. The humic acid lignite is measured by the belt conveyor and then enters the crusher, and the crusher is used for primary crushing. After the crusher comes out, it passes through the crushing belt and enters the drum screen for sieving. The qualified particle size enters the mixing mixer 1, and the unqualified particle size , transported by the return belt to the primary crusher for crushing;

[0034] S2. Pour the nitrogen, phosphorus and potassium materials into the feeding hopper. After being measured by the feeding belt, they respectively enter the belt at the entrance of the trommel sieve. After mixing, they enter the trommel sieve, and carry out uniform mixing in the trommel sieve. The uniform nitrogen, phosphorus and potassium materials are put into the mixer 1;

[0035] S3. Dry the organic matter such as livestock and p...

Embodiment 3

[0041] The technical method for the continuous activation production of active humic acid organic fertilizer comprises the following steps:

[0042] S1. The humic acid lignite is measured by the belt conveyor and then enters the crusher, and the crusher is used for primary crushing. After the crusher comes out, it passes through the crushing belt and enters the drum screen for sieving. The qualified particle size enters the mixing mixer 1, and the unqualified particle size , transported by the return belt to the primary crusher for crushing;

[0043] S2. Pour the nitrogen, phosphorus and potassium materials into the feeding hopper. After being measured by the feeding belt, they respectively enter the belt at the entrance of the trommel sieve. After mixing, they enter the trommel sieve, and carry out uniform mixing in the trommel sieve. The uniform nitrogen, phosphorus and potassium materials are put into the mixer 1;

[0044] S3. Dry the organic matter such as livestock and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com