Formula and production process of high-stability liquid calcium-zinc stabilizer

A liquid calcium-zinc and high-stability technology, which is applied in the formulation of high-stability liquid calcium-zinc stabilizer and its production process, can solve the problems affecting the stability of the stabilizer, easily causing coking, lack of raw material protection measures, etc., to reduce the The content of impurities and the effect of easy preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

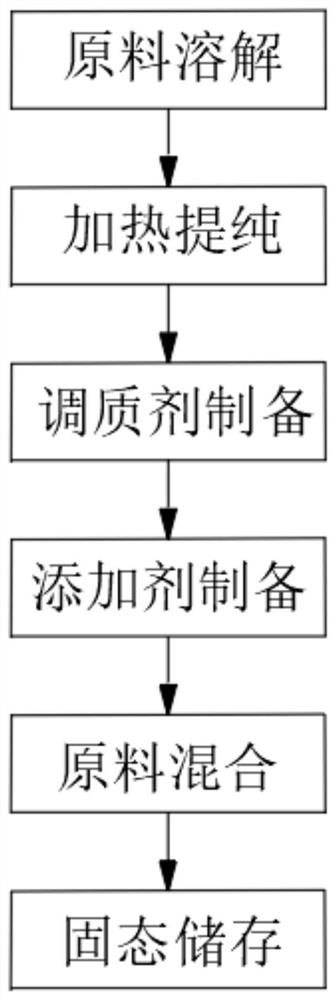

Image

Examples

Embodiment 1

[0029] S1: The raw materials are dissolved, take two sets of reaction containers and put them into zinc oxide and calcium oxide respectively, absorb dilute hydrochloric acid through a dropper, fully dissolve zinc oxide and calcium oxide by titration and dissolution, and form zinc chloride solution and calcium chloride solution ;

[0030] S2: Heating and purifying, putting the zinc chloride solution and the calcium chloride solution obtained in step 1 into heating containers respectively, increasing the temperature gradually, stirring slowly during the heating process, and obtaining the zinc chloride solution and the calcium chloride solution not containing dilute hydrochloric acid respectively. The clarified liquid of calcium chloride solution is left standstill for subsequent use;

[0031] S3: Preparation of conditioner, take half of the total mass of plasticizer and oxidant respectively into a dissolving container, add water to dissolve fully, heat slowly and stir after diss...

Embodiment 2

[0038] S1: The raw materials are dissolved, take two sets of reaction containers and put them into zinc oxide and calcium oxide respectively, absorb dilute hydrochloric acid through a dropper, fully dissolve zinc oxide and calcium oxide by titration and dissolution, and form zinc chloride solution and calcium chloride solution ;

[0039] S2: Heating and purifying, putting the zinc chloride solution and the calcium chloride solution obtained in step 1 into heating containers respectively, increasing the temperature gradually, stirring slowly during the heating process, and obtaining the zinc chloride solution and the calcium chloride solution not containing dilute hydrochloric acid respectively. The clarified liquid of calcium chloride solution is left standstill for subsequent use;

[0040] S3: Preparation of conditioner, take half of the total mass of plasticizer and oxidant respectively into a dissolving container, add water to fully dissolve, heat slowly and stir after diss...

Embodiment 3

[0047] S1: The raw materials are dissolved, take two sets of reaction containers and put them into zinc oxide and calcium oxide respectively, absorb dilute hydrochloric acid through a dropper, fully dissolve zinc oxide and calcium oxide by titration and dissolution, and form zinc chloride solution and calcium chloride solution ;

[0048] S2: Heating and purifying, putting the zinc chloride solution and the calcium chloride solution obtained in step 1 into heating containers respectively, increasing the temperature gradually, stirring slowly during the heating process, and obtaining the zinc chloride solution and the calcium chloride solution not containing dilute hydrochloric acid respectively. The clarified liquid of calcium chloride solution is left standstill for subsequent use;

[0049] S3: Preparation of conditioner, put half of the total mass of plasticizer and oxidant into a dissolving container, add water to fully dissolve, heat slowly and stir after dissolution, until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com