Preparation method of 1, 4-bis(4-phenoxy benzoyl) benzene and polyether ketone ketone

A technology of phenoxybenzoyl and phenoxybenzaldehyde, which is applied in the preparation of polyether ketone ketone and 1,4-bisphenyl, can solve the problems of waste of raw materials, increased procedures, and increased costs, and achieves The preparation method is effective, the content of impurities is reduced, and the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

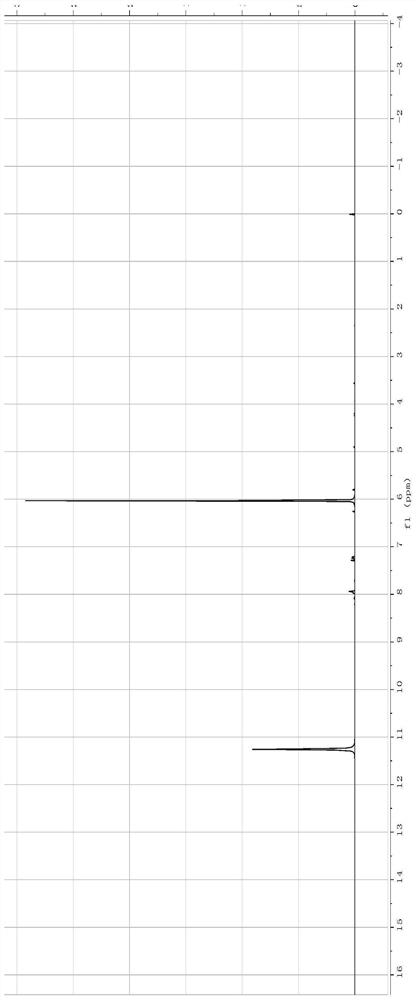

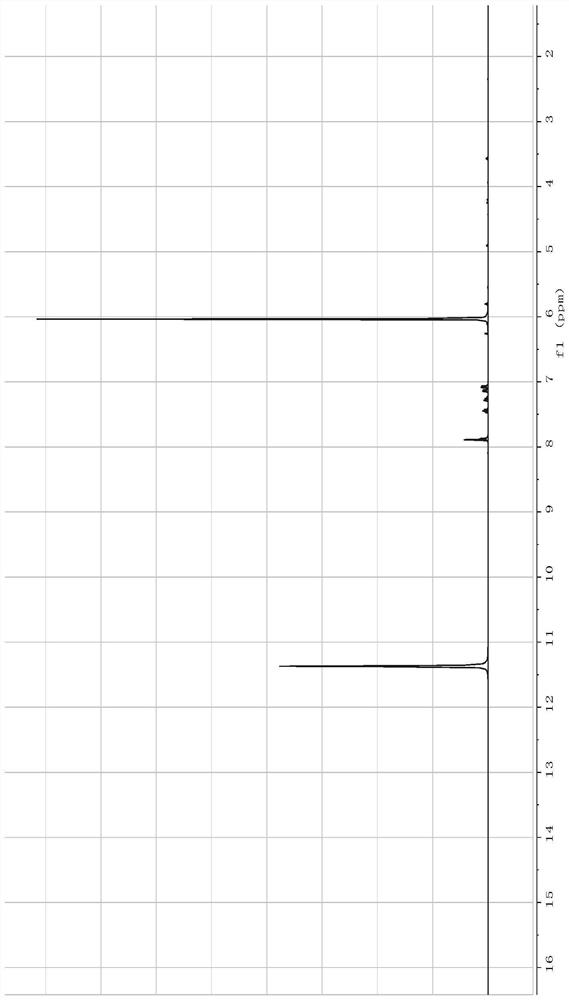

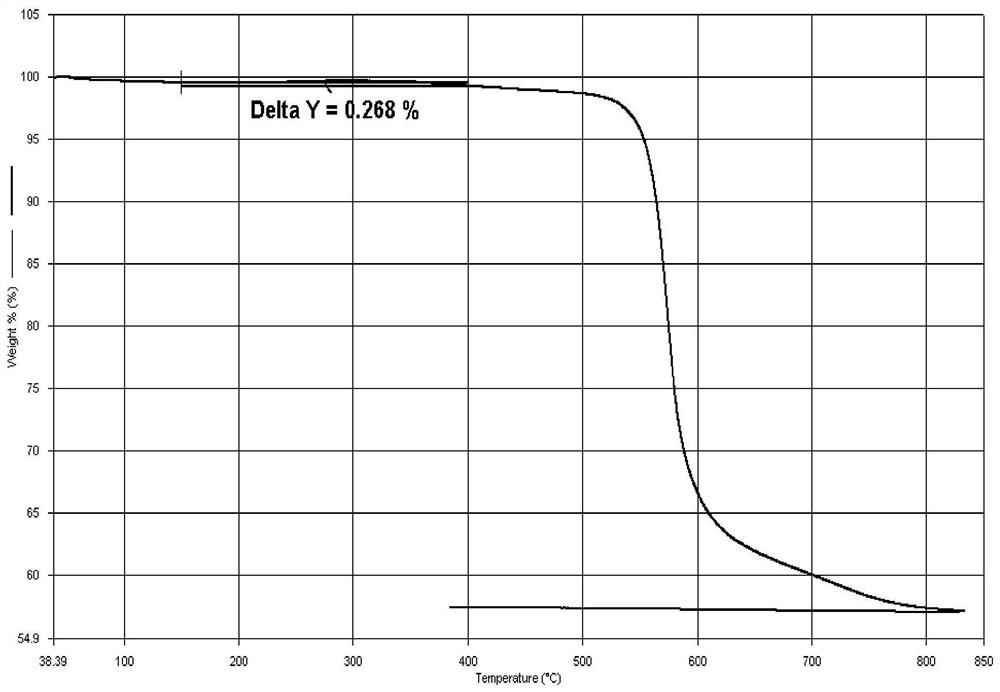

Image

Examples

preparation example Construction

[0038] The embodiment of the present invention provides a preparation method of 1,4 bis(4-phenoxybenzoyl)benzene, comprising the following steps:

[0039] S10, providing the reactant mixture comprising 4-phenoxybenzaldehyde shown in formula (2), terephthaloyl chloride shown in formula (3) and Lewis acid catalyst in solvent, carry out Friedel-Crafts acylation Reaction, to obtain the mixture that comprises the compound described in following formula (1), and

[0040] S20, performing oxidation reaction and deacidification reaction sequentially on the mixture containing the compound described in the following formula (1), so as to obtain a mixture containing 1,4 bis(4-phenoxybenzoyl)benzene.

[0041] The preparation method of traditional 1,4 bis(4-phenoxybenzoyl)benzene is to prepare 1,4 bis(4-phenoxybenzoyl)benzene with diphenyl ether and terephthaloyl chloride as raw materials , in the presence of a catalyst, terephthaloyl chloride can easily attack diphenyl ether to form xanth...

Embodiment 1

[0088] 1. Add 45g of anhydrous AlCl to a 500ml three-necked bottle equipped with magnetic stirring and gas conduit 3 , 4.5gCuCl, 300ml0-DCB, 16mlDPE, start stirring, heat to 25°C, continue to feed a mixed gas of CO and HCl (1:1), and react for 6h.

[0089] 2. Switch the incoming gas to nitrogen, add 10.15g of TPC to the three-necked flask, and continue the reaction for 10h.

[0090] 3. The gas is switched to oxygen to carry out the oxidation reaction, the heating temperature is raised to 35°C, and the reaction is continued for 1 hour.

[0091] 4. The gas is switched to nitrogen, and the heating temperature is increased to 125° C. for decarboxylation reaction, and the reaction is continued for 1 hour.

[0092] 5. After the reaction is completed, slowly add 200ml of ice methanol to quench, filter, and wash with methanol and deionized water repeatedly until there is no organic residue and the filtrate is neutral. Finally, the product was dried in a vacuum oven at 150° C. to a c...

Embodiment 2

[0094] The preparation method of Example 2 is basically the same as that of Example 1, except that the molar ratio of CO and HCl in the mixed gas of CO and HCl is 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com