Preparation technology of niobium bar

A preparation process, the technology of niobium bar, applied in the field of metal preparation process, can solve the problems of low purity, cumbersome process flow, and low total output, and achieve the effects of reducing the content of impurities, benefiting environmental governance, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

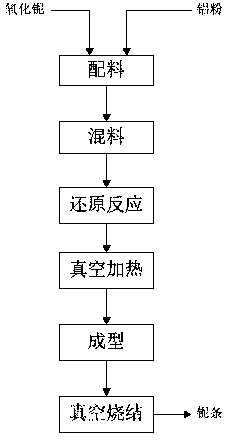

[0021] A kind of preparation technology of niobium bar, adopts the aluminothermic reduction method, comprises the following specific steps:

[0022] a, batching, prepare niobium oxide and aluminum powder, aluminum powder is the aluminum powder of 30-150 mesh sieve;

[0023] b. Mixing materials, mix the niobium oxide and aluminum powder evenly and pour into the crucible, then cover the mixture of niobium oxide and aluminum powder with a layer of aluminum powder;

[0024] c. Reduction reaction, heat the crucible to 800-1200°C to ignite the reaction, carry out the reduction reaction, and the reduction product is niobium thermite;

[0025] d. Heating in vacuum, cooling the obtained niobium thermite to 60-80°C and then putting it into a vacuum furnace for secondary heating and reduction. During the secondary heating, the temperature in the vacuum furnace rises to 1050-1450°C, and the temperature is kept for 5- 10 hours, then raise the temperature in the vacuum furnace to 1350-1850...

Embodiment 1

[0033] Mix 94% niobium oxide and 4% aluminum powder evenly and pour it into the crucible, and then cover a layer of 2% aluminum powder on the mixture of niobium oxide and aluminum powder, wherein the aluminum powder is aluminum powder with a 120-mesh sieve . Heat the crucible to 1080°C to ignite the reaction and carry out the reduction reaction, and the reduction product is niobium thermite; cool the obtained niobium thermite to 75°C and put it into a vacuum furnace for secondary heating and reduction. During the secondary heating, the vacuum The temperature in the furnace is raised to 1100°C and kept for 10 hours, then the temperature in the vacuum furnace is raised to 1500°C, kept for 20 hours, and finally the temperature in the vacuum furnace is raised to 2250°C to make the vacuum degree in the vacuum furnace Reaching 7pa, through several consecutive high-temperature heating, under high-temperature vacuum conditions, Al, Al 2 O and NbO are volatilized from the niobium ther...

Embodiment 2

[0035] Mix 96% niobium oxide and 3% aluminum powder evenly and pour into the crucible, then cover a layer of 1% aluminum powder on the mixture of niobium oxide and aluminum powder, wherein the aluminum powder is aluminum powder with 80 mesh sieve . Heat the crucible to 1020°C to ignite the reaction and carry out the reduction reaction. The reduction product is niobium thermite; the obtained niobium thermite is cooled to 65°C and then placed in a vacuum furnace for secondary heating and reduction. During the secondary heating, the vacuum The temperature in the furnace is raised to 1250°C and kept for 8 hours, then the temperature in the vacuum furnace is raised to 1650°C and kept for 18 hours, and finally the temperature in the vacuum furnace is raised to 1950°C to make the vacuum degree in the vacuum furnace Reaching 6pa, through several consecutive high-temperature heating, under high-temperature vacuum conditions, Al, Al 2 O and NbO are volatilized from the niobium thermite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com