Modified asphalt as well as preparation method and application thereof

A technology for modifying asphalt and petroleum asphalt, applied in building components, building insulation materials, buildings, etc., can solve the problems of large amount of polyurethane doping, need to be improved, poor flexibility, etc., achieve good interaction and achieve sustainable development , the effect of excellent high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

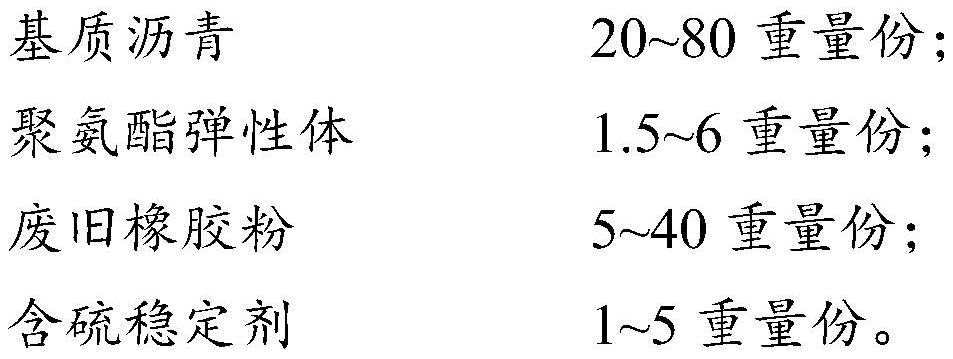

[0036] The raw materials for preparing the modified asphalt provided by the invention include base asphalt. The parts by weight of the base pitch are 20-80 parts. In some embodiments of the present invention, the base asphalt has 78, 73 or 69 parts by weight.

[0037] In some embodiments of the present invention, the base asphalt includes at least one of 50# petroleum asphalt, 70# petroleum asphalt, 90# petroleum asphalt and 110# petroleum asphalt; preferably 70# petroleum asphalt or 90# petroleum asphalt . The present invention does not have special restriction to the source of described matrix bitumen, adopts the commercially available commodity of 50# petroleum pitch, 70# petroleum pitch, 90# petroleum pitch and 110# petroleum pitch well known to those skilled in the art.

[0038] The raw material for preparing the modified asphalt provided by the invention also includes polyurethane elastomer. The parts by weight of the polyurethane elastomer are 1.5 to 6 parts. In som...

Embodiment 1

[0071] 1) Heating 78 parts by weight of 70# petroleum asphalt to 170°C and adding it to the colloid mill;

[0072] 2) Add 18 parts by weight of 40-mesh rubber powder and 1.5 parts by weight of sulfur-containing stabilizer to the colloid mill, and mix and grind for 30 minutes at 160° C. at a speed of 600 r / min to obtain a modified material;

[0073] 3) Put the modified material obtained in step 2) in the development tank, and develop it at 180°C for 90 minutes under the condition of stirring (100r / min);

[0074] 4) Add the modified material developed in step 3) and 2.5 parts by weight of polyurethane elastomer to the colloid mill respectively, and mix and grind for 30 minutes at 180° C. at a speed of 600 r / min to obtain modified asphalt.

Embodiment 2

[0076] 1) Heat 73 parts by weight of 90# petroleum asphalt to 180°C and add it to the colloid mill;

[0077] 2) Add 22 parts by weight of 40-mesh rubber powder and 2 parts by weight of sulfur-containing stabilizer to the colloid mill respectively, and mix and grind for 50 minutes at 160° C. at a speed of 600 r / min to obtain a modified material;

[0078] 3) Put the modified material obtained in step 2) in the development tank, and develop it at 180°C for 90 minutes under the condition of stirring (100r / min);

[0079] 4) Add the modified material developed in step 3) and 3 parts by weight of the polyurethane elastomer into the colloid mill respectively, and mix and grind for 30 minutes at 180° C. at a speed of 600 r / min to obtain modified asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com