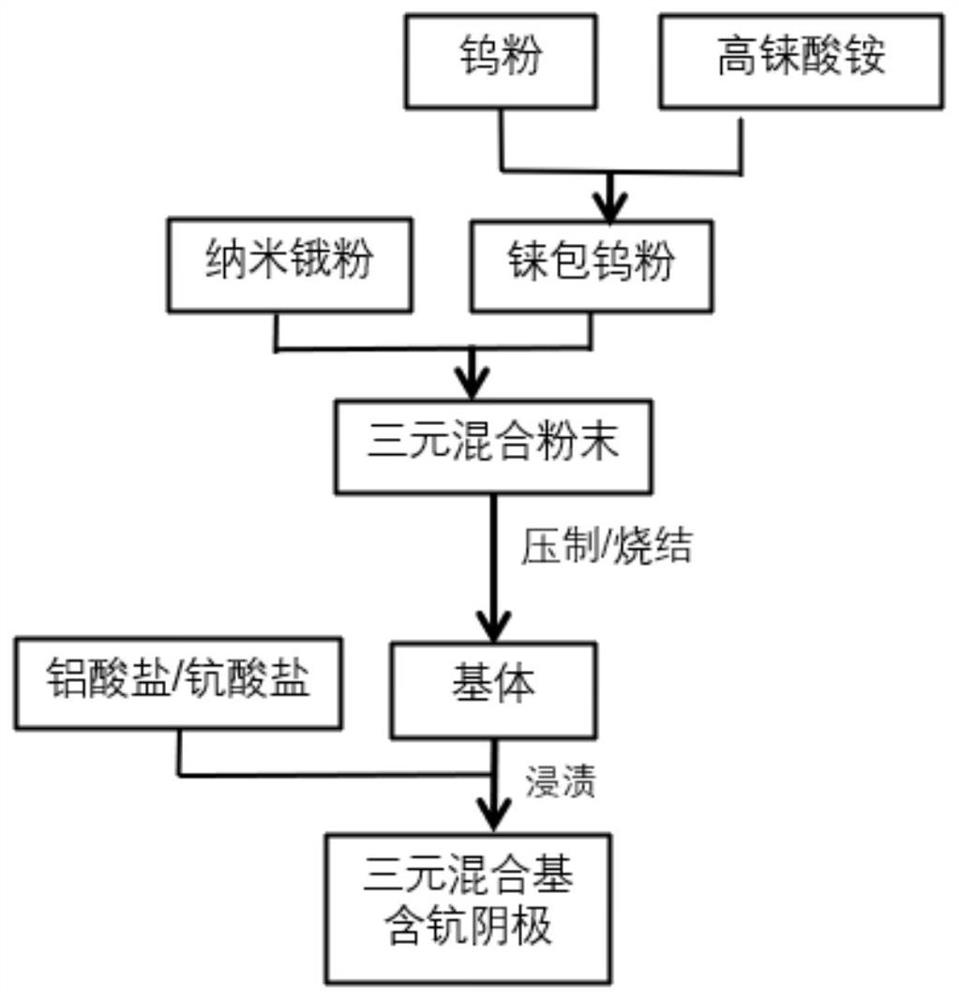

Preparation method of dipping type tungsten-rhenium-osmium ternary mixed base diffusion cathode

A diffusion cathode, mixed-base technology, applied in cold cathode manufacturing, thermionic cathode manufacturing, electrode system manufacturing, etc., can solve the problems of increased cathode preparation cost, high price, and little research on ternary mixed-base cathodes. dosage, increase the emission current density, and improve the effect of electron emission density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

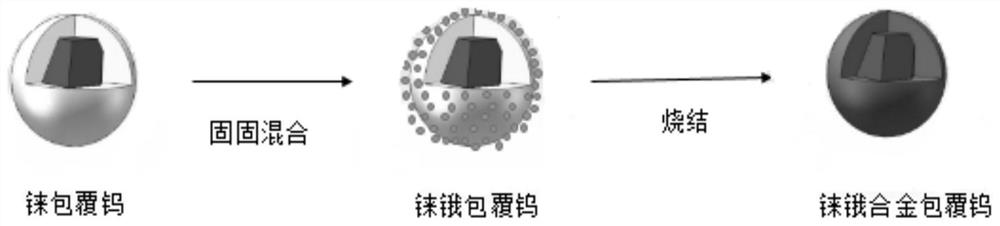

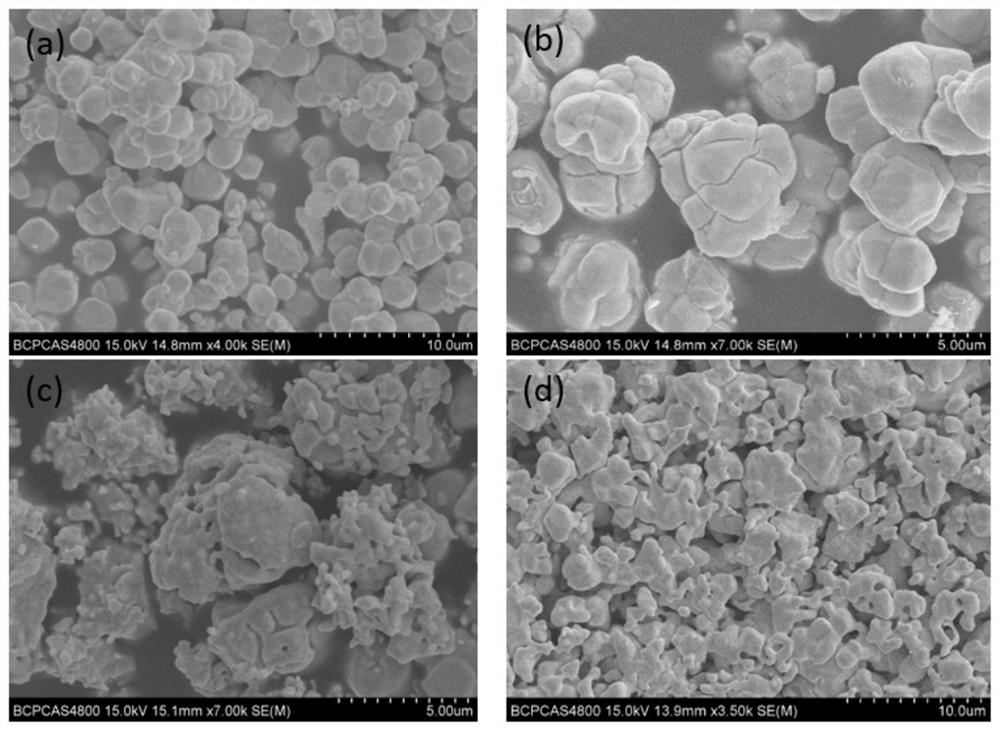

[0028] Add 8g of nanoscale osmium powder to the rhenium-coated tungsten powder, and heat the uniformly mixed ternary powder in a high-temperature hydrogen furnace at 1300°C for 30 minutes to obtain a ternary powder containing 50% tungsten, 25% rhenium, and 25% osmium. Mixed powder, its shape is as image 3 (c) shown.

[0029] Compression and sintering of the ternary mixed base powder: weigh the ternary mixed base powder, put it into a grinding tool with an inner diameter of 3mm, and use a powder tablet press for bidirectional molding. Under the pressure of 0.8Mp, hold the pressure for 25S to obtain a sintered green body; keep the green body in a high-temperature hydrogen furnace at 1500°C for 30min to obtain a ternary mixed base cathode substrate, the microstructure is as follows image 3 (d) shown.

[0030] The ternary mixed matrix was impregnated with 411 metal salt at 1750°C, and after salt washing and annealing treatment (under hydrogen, at a temperature of 1000°C for 1 ...

Embodiment 2

[0033] Add 4g of nanoscale osmium powder to the rhenium-coated tungsten powder, and heat the uniformly mixed ternary powder in a high-temperature hydrogen furnace at 1300°C for 30 minutes to obtain a ternary powder containing 57% tungsten, 29% rhenium, and 14% osmium. Mix powder, other is with embodiment 1.

[0034] As in Example 1, the ternary mixed powder was subjected to pressing, sintering, salt washing and annealing to obtain a ternary mixed base cathode. The test results obtained after the pulse emission test are as follows: Figure 4 .

Embodiment 3

[0036] Add 16g of nanoscale osmium powder to the rhenium-coated tungsten powder, and keep the uniformly mixed ternary mixed powder in a high-temperature hydrogen furnace at 1300°C for 30 minutes to obtain a ternary powder containing 40% tungsten, 20% rhenium, and 40% osmium. Mix powder, other is with embodiment 1.

[0037] As in Example 1, the ternary mixed powder was subjected to pressing, sintering, salt washing and annealing to obtain a ternary mixed base cathode. The test results obtained after the pulse emission test are as follows: Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com