Method for enhancing field emission performance of single-walled carbon nanotube films by laser nano-welding

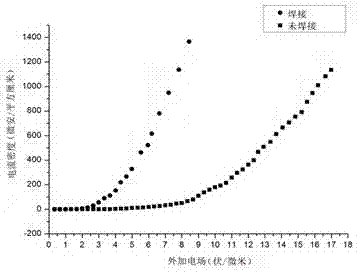

A technology of single-walled carbon nanotubes and field emission, applied in laser welding equipment, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem that the development of laser nano-welding technology is not mature enough and limits the development of the field of nanoelectronics And application, fixed one-time welding area and other issues, to achieve the effect of strong mechanical properties, high emission current density, and small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The method includes the following steps:

[0019] 1) Pretreatment of the surface of the metal substrate, put the metal substrate into anhydrous ethanol or acetone solution, the metal substrate is any one of Al, Ni, Ti or Cu, and perform ultrasonic cleaning in an ultrasonic pool. The ultrasonic time is 10-15 minutes;

[0020] 2) Depositing a single-walled carbon nanotube film on the surface of the metal substrate treated in step 1) by a deposition method, the deposition method being electrophoretic deposition or spin coating;

[0021] 3) Apply laser nano-welding to the single-wall carbon nanotube film deposited on the surface of the metal substrate in step 2). Under the joint action of laser energy and shock waves, the single-wall carbon nanotube film is pressed into the surface layer of the molten metal substrate. The rapid cooling of the molten metal after scanning, the single-walled carbon nanotube film embedded in the surface of the metal substrate to form a stable ...

Embodiment 2

[0023] The method includes the following steps:

[0024] 1) Pre-treat the surface of the aluminum substrate, put the aluminum substrate in absolute ethanol solution, and ultrasonically clean it in an ultrasonic pool for 10 minutes;

[0025] 2) Deposit single-walled carbon nanotube films on the surface of aluminum by electrophoretic deposition, 2mg single-walled carbon nanotubes and 2mg Mg(NO 3 ) 2 6H 2 O was added in 100ml isopropanol solution to make electrophoresis solution, electrophoresis conditions, stainless steel plate as anode, aluminum as cathode, two electrode spacing 2cm, electrophoresis voltage 30V, electrophoresis time 10min;

[0026] 3) Laser nano-welding is performed on samples deposited with single-walled carbon nanotube films, using picosecond pulse CO 2 Laser, the laser beam diameter is 8μm, the laser wavelength is 1064nm, the laser repetition frequency is 100kHz, the laser power is 50mW, the laser scanning speed is 100mm / min, the negative defocus is 0.08m...

Embodiment 3

[0028] The method includes the following steps:

[0029] 1) Pre-treat the surface of the nickel substrate, put the nickel substrate in acetone solution, and ultrasonically clean it in an ultrasonic pool for 15 minutes;

[0030] 2) Using electrophoretic deposition method to deposit single-walled carbon nanotube film on nickel surface, 2mg single-walled carbon nanotube and 2mg Mg(NO 3 ) 2 6H 2 O was added in 100ml isopropanol solution to make electrophoresis solution, electrophoresis conditions, stainless steel plate as anode, nickel as cathode, two electrode spacing 2cm, electrophoresis voltage 30V, electrophoresis time 8min;

[0031] 3) Laser nano-welding is performed on samples deposited with single-walled carbon nanotube films, using picosecond pulse CO 2 Laser, the beam diameter of the laser is 8μm, the wavelength of the laser is 1064nm, the weight of the laser

[0032] The complex frequency is 100kHz, the laser power is 115mW, the laser scanning speed is 100mm / min, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com