Electrolytic polishing solution and electrolytic polishing method for preparing nickel-based superalloy needle tip sample

A nickel-based high-temperature alloy and electrolytic polishing technology, which is applied in the field of electrolytic polishing, can solve the problems of difficult preparation of needle tip samples, low quality of needle tip, and low production efficiency, and achieve the effects of simple configuration, improved efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

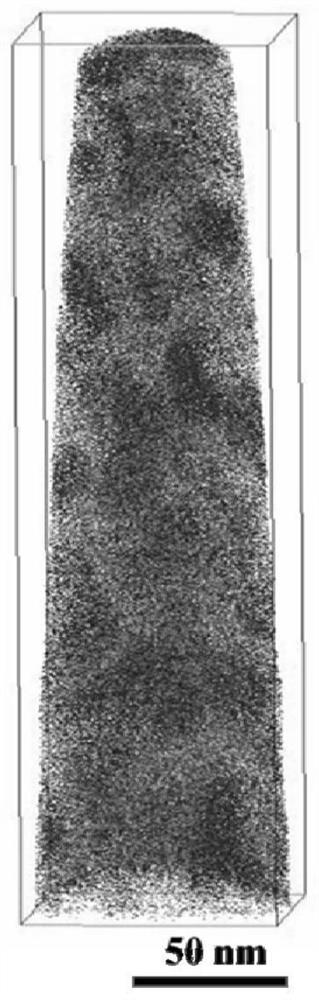

[0024] In this embodiment, the needle tip sample is prepared by electrolytic polishing method for the nickel-based superalloy GH4169. In the rough polishing electrolyte, by volume percentage, perchloric acid is 8%, and ethylene glycol butyl ether is 92%. In the fine polishing electrolyte, by volume percentage, perchloric acid is 4%, and ethylene glycol butyl ether is 96%.

[0025] The electrolytic polishing solution is used to prepare nickel-based superalloy tip samples, and the specific steps are as follows:

[0026] (1) Prepare the nickel-based superalloy into a filament-shaped sample blank of 0.5mm×0.5mm×15mm by tangential cutting. The sample blank is used as the anode and connected to the positive electrode of the DC power supply; the platinum wire ring is used as the cathode and connected to the DC power supply. The inner diameter of the platinum wire ring is about 3 mm, and the outer diameter of the platinum wire ring is about 3.5 mm; the sample blank is inserted vertic...

Embodiment 2

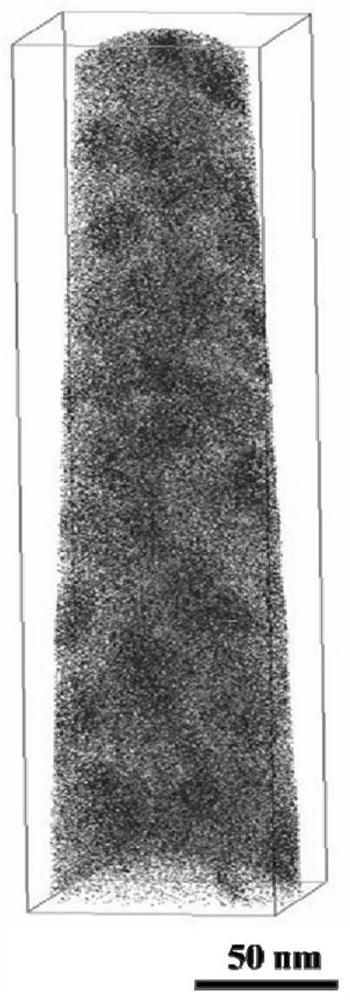

[0031] In this example, a needle tip sample was prepared by electrolytic polishing method for the nickel-based superalloy GH4169 with Ce added. In the rough polishing electrolyte, by volume percentage, perchloric acid is 15%, and ethylene glycol butyl ether is 85%. In the fine polishing electrolyte, the content of perchloric acid is 2% by volume, and ethylene glycol butyl ether is 98%. Prepare needle-tip samples following the electrolytic polishing procedure in the manual.

[0032] The electrolytic polishing solution is used to prepare nickel-based superalloy tip samples, and the specific steps are as follows:

[0033] (1) Prepare the nickel-based superalloy into a filament-shaped sample blank of 0.5mm×0.5mm×15mm by tangential cutting. The sample blank is used as the anode and connected to the positive electrode of the DC power supply; the platinum wire ring is used as the cathode and connected to the DC power supply. The inner diameter of the platinum wire ring is about 3 m...

Embodiment 3

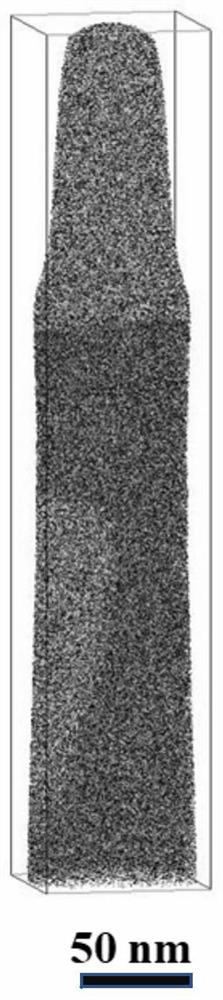

[0038] In this embodiment, the needle tip sample is prepared by electrolytic polishing method for the nickel-based superalloy K416B. In the rough polishing electrolyte, by volume percentage, perchloric acid is 10%, and ethylene glycol butyl ether is 90%. In the fine polishing electrolyte, the volume percentage content of perchloric acid is 3%, and ethylene glycol butyl ether is 97%. Prepare needle-tip samples following the electrolytic polishing procedure in the manual.

[0039]The electrolytic polishing solution is used to prepare nickel-based superalloy tip samples, and the specific steps are as follows:

[0040] (1) Prepare the nickel-based superalloy into a filament-shaped sample blank of 0.5mm×0.5mm×15mm by tangential cutting. The sample blank is used as the anode and connected to the positive electrode of the DC power supply; the platinum wire ring is used as the cathode and connected to the DC power supply. The inner diameter of the platinum wire ring is about 3 mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com