Wet etching method and distributed parameter circuit layout

A wet etching and etchant technology, which is used in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of the influence of the electromagnetic field of the layout, unqualified product appearance, etc., and achieves fast etching speed and shortened etching time. , the effect of thorough etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

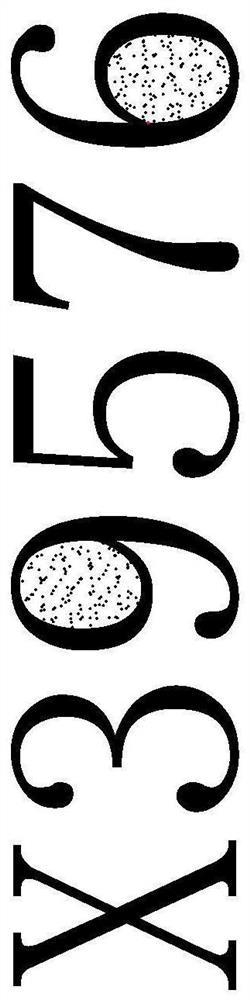

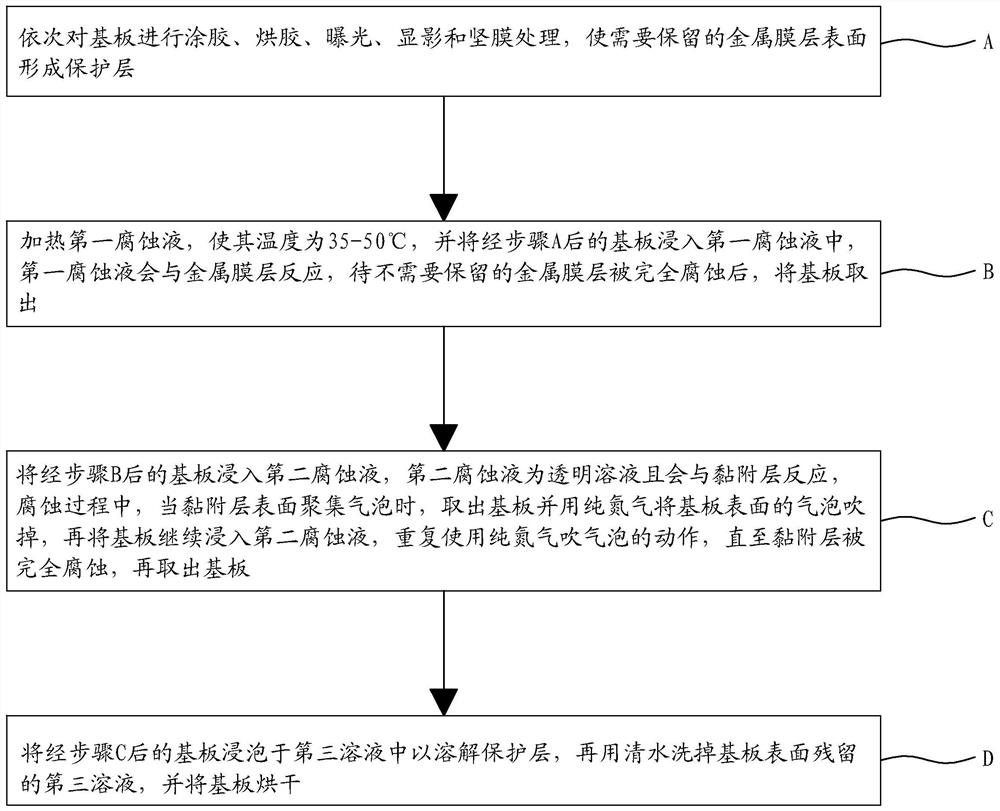

[0032] Such as figure 1 As shown, there are metal film residues in the circles of the number "9" and the number "6". This is because the chemical reaction of metal corrosion usually produces bubbles. On the surface of the corrosion area, a layer of bubble protection layer is formed, especially in the circle where the bubbles are more conducive to adhesion, it is easier to form a bubble protection layer, and the bubble protection layer isolates the metal film layer from the corrosion solution, which eventually leads to incomplete corrosion. use as figure 2 The wet etching method shown can avoid the above phenomenon. This wet etching method is used to etch the metal film layer on the surface of the substrate. The substrate is a ceramic substrate, and the metal film layer is generally made of good conductors such as copper or gold. However, the good conductor metal has poor adhesion on the substrate and cannot meet the reliability requirements. Therefore, an intermediate transi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com