Preparation method of amido modified ferrihydrite material and application thereof

A technology for modifying water and iron ore, which is applied in the field of material technology and pollutant treatment, can solve the problems of limited adsorption capacity of iron water ore, and achieve the effects of fast adsorption rate, enhanced adsorption effect, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

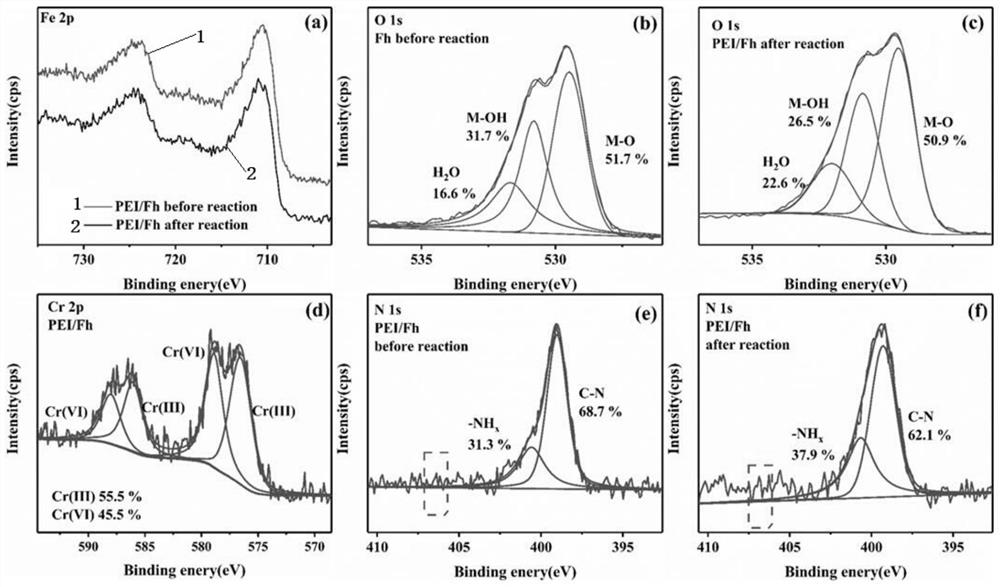

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1), the ferric chloride hexahydrate of 5.41g is added into 100mL deionized water to form 0.2mol / L Fe 3+ solution.

[0033] Step 2), use NaOH solution and HCl solution to adjust the pH to 7.5±0.1, continue to stir for 1h, and age for 12h.

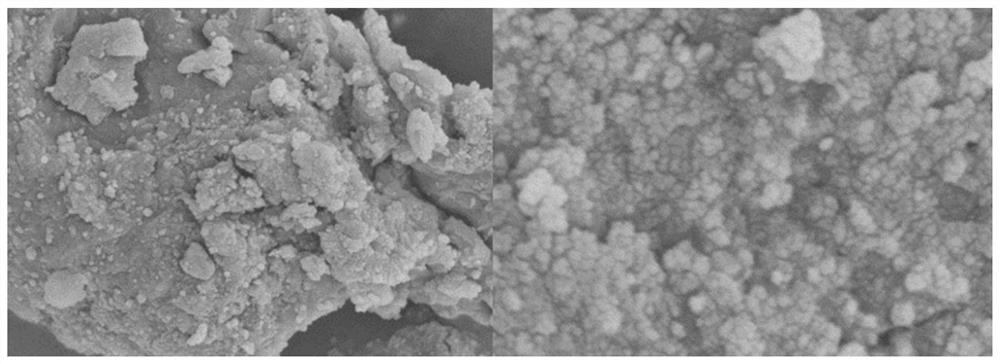

[0034] Step 3), centrifuge, separate the precipitate and wash with deionized water until the supernatant is free of Cl - , put the obtained brown-red precipitate in an oven at 60° C. for 12 h, and grind the dried product with an agate mortar.

Embodiment 2

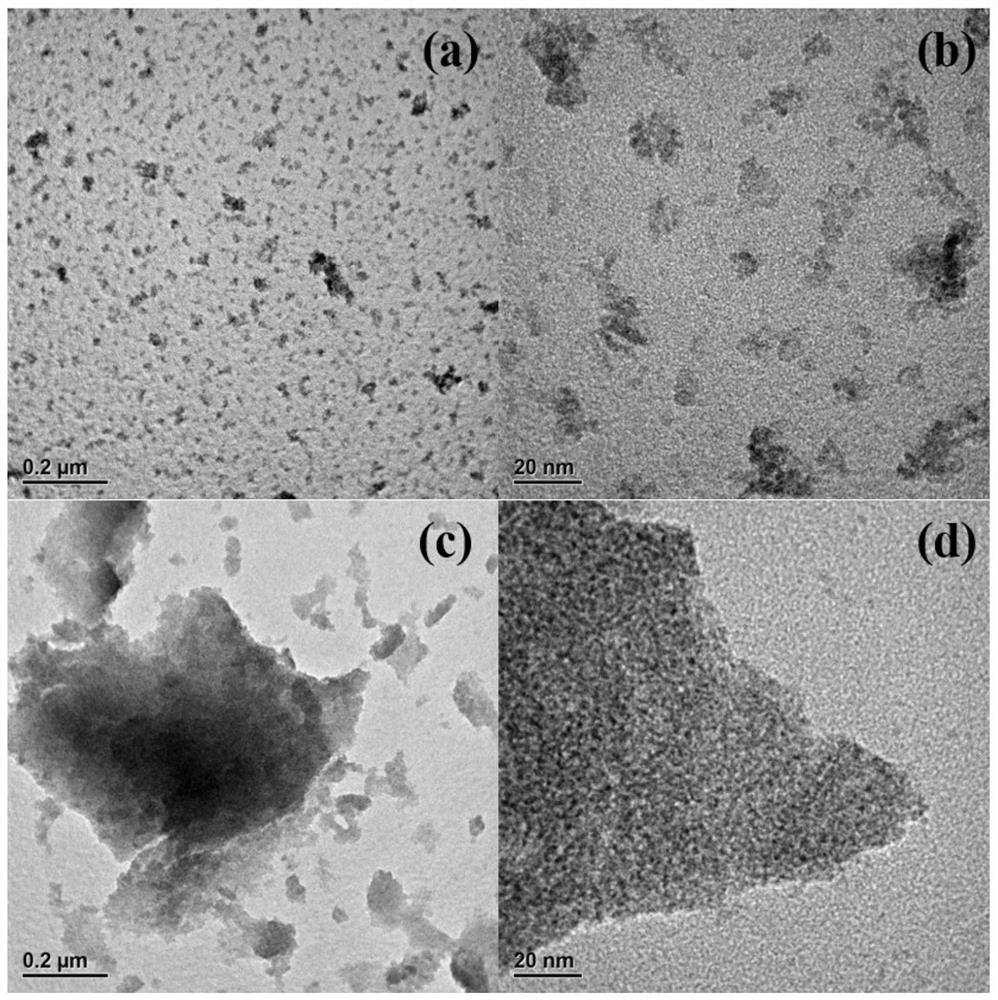

[0036] Step 1), take 0.2g of the sample in Example 1, soak it in 100mL deionized water, and stir.

[0037] In step 2), 4 mL of polyethyleneimine was dissolved in 40 mL of ethanol, and stirred continuously for 30 min to form a uniform solution, which was added to step 1 dropwise.

[0038] Step 3), use NaOH solution and HCl solution to adjust the pH to 7.5±0.1, continue to stir for 1h, and age for 12h.

[0039] Step 4), centrifuge, separate the precipitate and wash with deionized water until the supernatant is free of Cl - , put the obtained brown-red precipitate in an oven at 60° C. for 12 h, and grind the dried product with an agate mortar.

Embodiment 3

[0041] Step 1), the ferric chloride hexahydrate of 5.41g is added into 100mL deionized water to form 0.2mol / L Fe 3+ solution.

[0042] Step 2), take 0.5mL polyethyleneimine and dissolve it in 40mL ethanol, keep stirring for 30min to form a uniform solution, and add it into step 1 dropwise.

[0043] Step 3), use NaOH solution and HCl solution to adjust the pH to 7.5±0.1, continue to stir for 1h, and age for 12h.

[0044]Step 4), centrifuge, separate the precipitate and wash with deionized water until the supernatant is free of Cl - , put the obtained brown-red precipitate in an oven at 60° C. for 12 h, and grind the dried product with an agate mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com