Method for scratching and splitting solar cell and scratching and splitting equipment for scratching and splitting solar cell

A technology of solar cells and cells, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of cell cracking, precise control of difficult cooling medium, cell fouling, etc., and achieve extremely low thermal expansion coefficient, improving scribing quality and efficiency, and avoiding fouling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

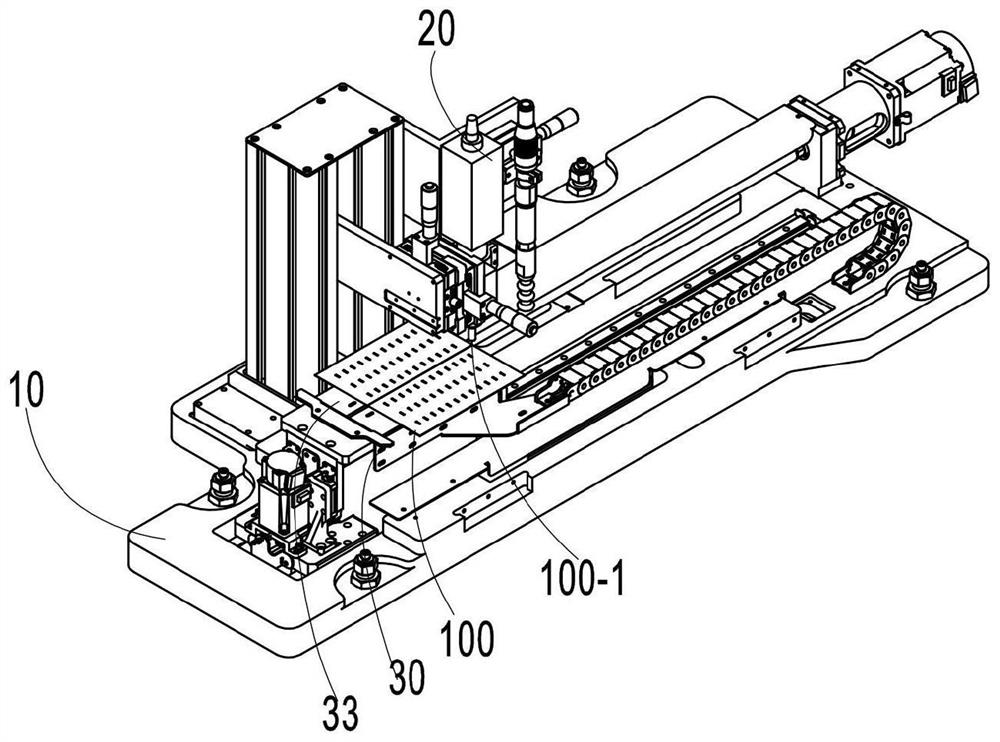

[0048] figure 1 A method for scribing a solar cell sheet is illustrated. In this embodiment, taking economical and material properties into consideration, the bearing platform of low thermal conductivity and high temperature resistant material is made of quartz glass.

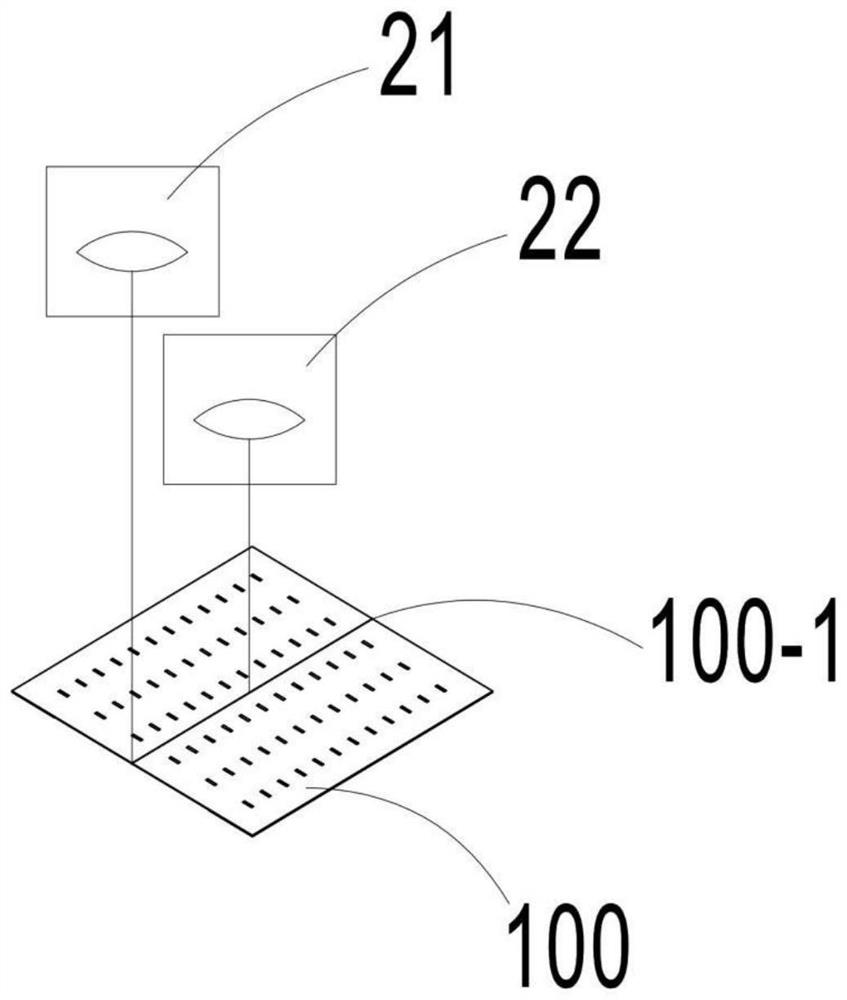

[0049] Firstly, the first laser beam and the second laser beam are applied to the coincident position with the line to be split of the battery sheet, and then the quartz glass carrier of the battery sheet transmission part carries the solar battery sheet 100 through the first laser beam and the second laser beam , where the first laser beam ablates the cell to be split line 100-1 with a certain length of groove, the second laser beam heats the cell to be split line along the split line and its extension line, the solar cell Break along the line to be split to complete the scribing of solar cells.

[0050] When the quartz glass carrying platform carries the solar cells through the focusing point of the first l...

Embodiment 2

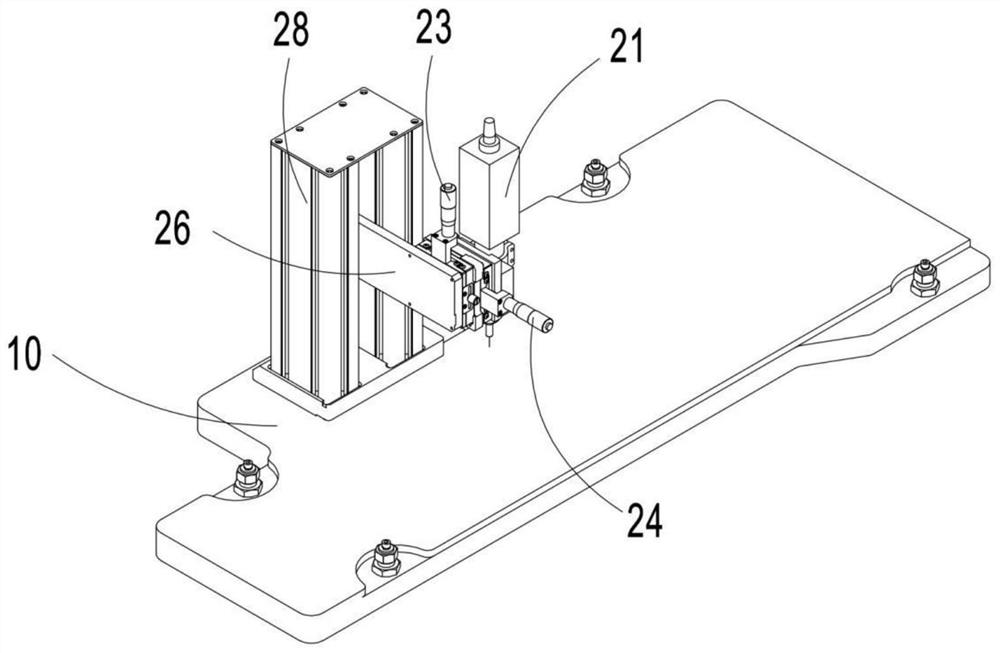

[0066] Figure 8 It shows a schematic diagram of the moving direction of each component when the battery sheet 100 is cut. The difference between the second embodiment and the first embodiment is that the quartz glass carrier and the battery sheet 100 are fixedly arranged, and the first laser 21 and the second laser 22 are in the movement mechanism. Driven to move in the direction of the arrow to complete the cutting of the battery sheet 100 .

[0067] Working principle: Manually adjust the first laser up and down fine-tuning assembly 23 and the first laser horizontal fine-tuning assembly 24, so that the laser focus point emitted by the first laser 21 is located on the line to be split 100-1 in the middle of the solar cell 100; manually adjust the second The laser trimming assembly 25 makes the focal point of the laser emitted by the second laser 22 coincide with the focal point of the first laser.

[0068] The lifting drive assembly 32 moves to the front end of the equipment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com