Cationic anti-collapse agent for water-based drilling fluid, preparation method and application thereof

A technology of water-based drilling fluid and cation, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor wettability inversion effect, poor hydration of shale surface, poor compatibility of drilling fluid, etc., and achieve excellent Inhibit the anti-slump performance, maintain the stability of the borehole wall, and reduce the effect of negative charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

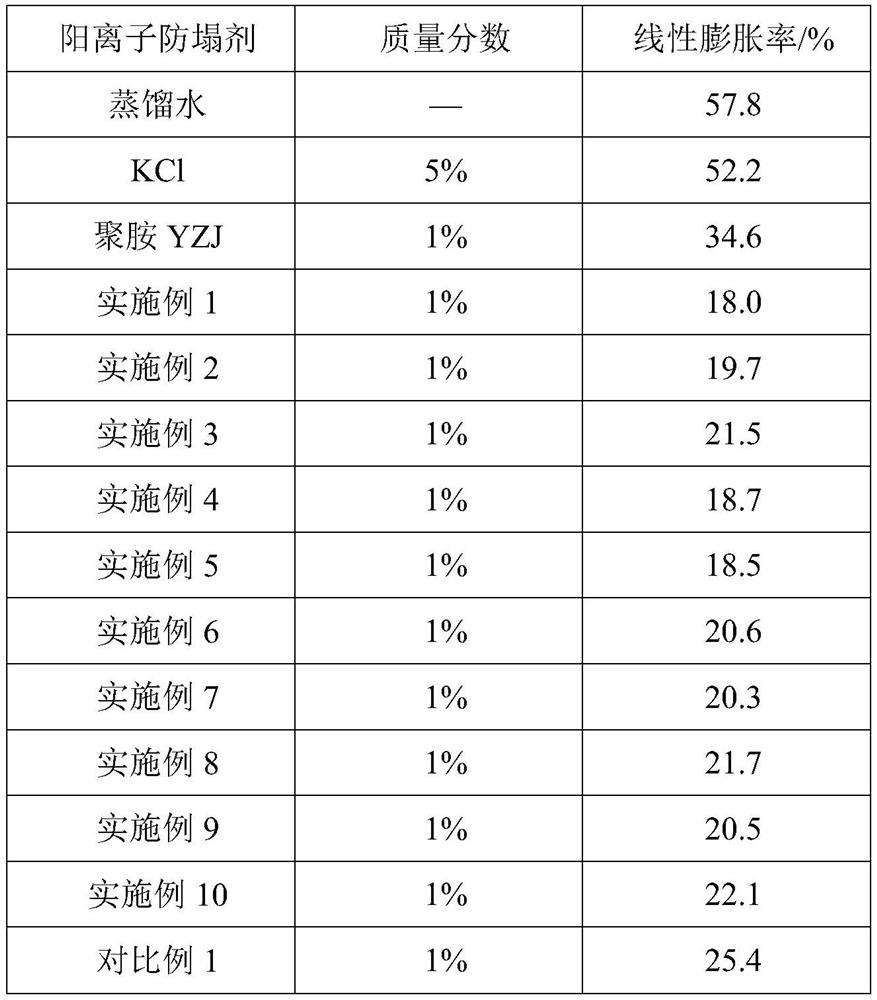

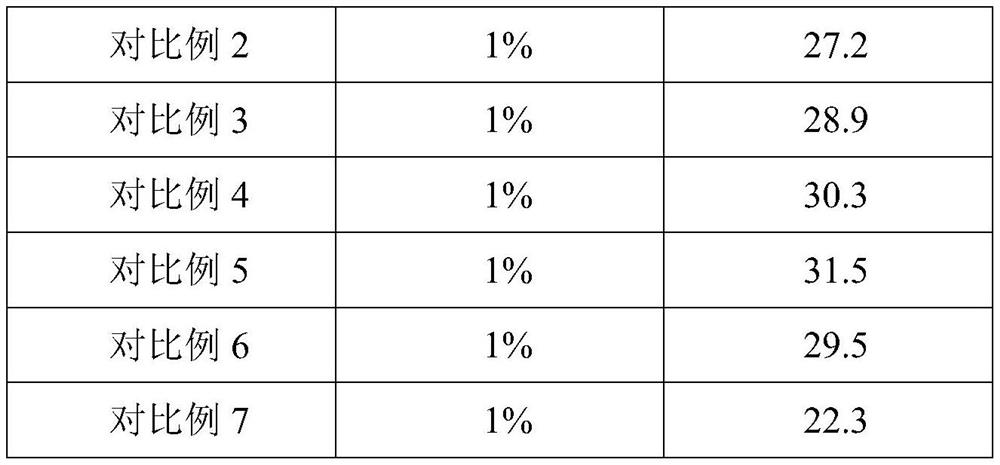

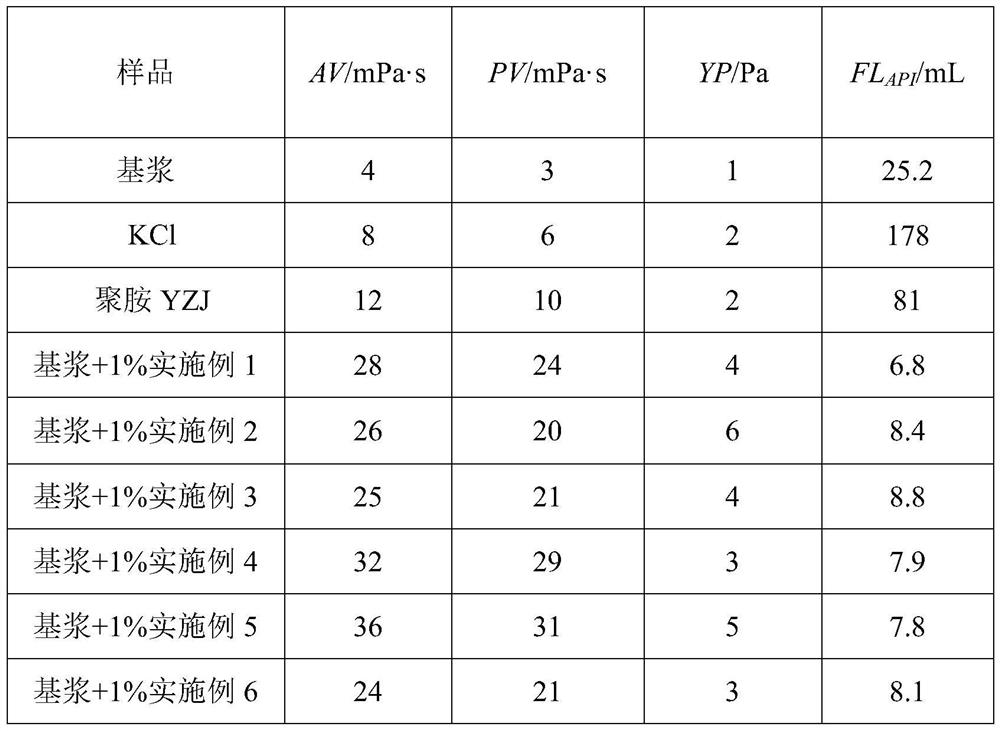

Examples

Embodiment 1

[0028] A cationic anti-slump agent for water-based drilling fluid, comprising the following raw materials in parts by mass: 6 parts of acrylamide, 1.5 parts of cationic monomer, 1 part of hydrophobic monomer, 0.5 part of modified silicon dioxide, 0.1 part of initiator, 40 parts of ethanol;

[0029] Wherein, the cationic monomer is dimethyl diallyl ammonium chloride; the hydrophobic monomer is dioctyl maleate; and the initiator is ammonium persulfate.

[0030] The modified silicon dioxide is prepared according to the following method:

[0031] Add nano-silica with a particle size of 20nm into ethanol, and disperse evenly by ultrasonic, then add silane coupling agent KH570, and react at 80°C for 8 hours; after the reaction is completed, filter with suction, wash with deionized water for 3 times, and dry , to obtain modified silicon dioxide; the mass ratio of ethanol to nanometer silicon dioxide is 20:1, and the mass ratio of the silane coupling agent KH570 to nanometer silicon ...

Embodiment 2

[0035] A cationic anti-slump agent for water-based drilling fluid is as described in Example 1, and its preparation method is as described in Example 1, except that the reaction temperature is 65°C.

Embodiment 3

[0037] A cationic anti-slump agent for water-based drilling fluid is as described in Example 1, and its preparation method is as described in Example 1, except that the reaction temperature is 75°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com