Tray device for growing crystals by horizontal directional crystallization method and use method

A technology of growing crystals and horizontal orientation, applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve problems such as temperature field asymmetry, increased crystal stress, warping deformation, etc., to achieve the effect of eliminating deformation and suppressing guide rails Deformation, long-term flat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

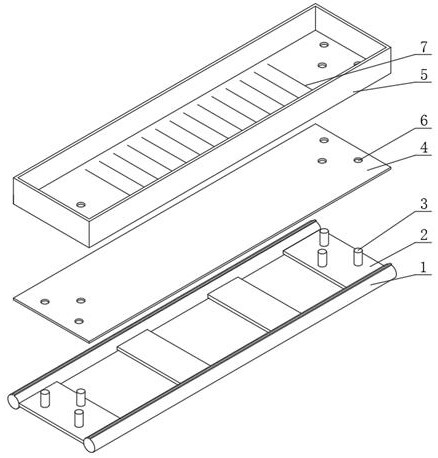

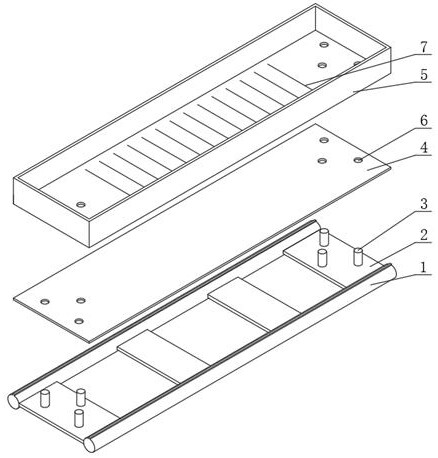

[0038] Nd:YAG crystals were grown using a tray device for crystal growth by horizontal oriented crystallization.

[0039]The guide rail is composed of two cylindrical molybdenum rods. There are 4 horizontal plates between the two molybdenum rods. There are 3 positioning columns on the horizontal plates at both ends of the guide. The height of the positioning columns is 5mm and the diameter is 4mm. The thickness of the buffer plate is 1mm, the length is 500mm, and the width is 120mm. The size of the bottom of the tray is 500×120mm, and the height of the tray wall is 50mm. There is a positioning hole at the corresponding position of the buffer plate and the tray, which has the same size as the positioning column. The size of the positioning hole relative to the positioning column has a positive tolerance, and the tolerance is not greater than 0.2mm. Tungsten wire diameter is 0.5mm.

[0040] When in use, first install the buffer plate on the guide rail from the vertical directi...

Embodiment 2

[0042] Large-sized Yb:YAG crystals were grown using a tray device for crystal growth by horizontal oriented crystallization.

[0043] The guide rail is composed of two cylindrical molybdenum rods. There are 5 horizontal plates between the two molybdenum rods. There are 4 positioning columns on the horizontal plates at both ends of the guide rail. The height of the positioning columns is 8mm and the diameter is 5mm. The thickness of the buffer plate is 1mm, the length is 600mm, and the width is 220mm. The size of the bottom of the tray is 600×220mm, and the height of the tray wall is 60mm. There is a positioning hole at the corresponding position of the buffer plate and the tray, which has the same size as the positioning column. The size of the positioning hole relative to the positioning column has a positive tolerance, and the tolerance is not greater than 0.2mm. Tungsten wire diameter is 0.8mm.

[0044] When in use, first install the buffer plate on the guide rail from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com