Printing and dyeing method for pure cotton fabric with silk-like luster

A pure cotton and fabric technology, applied in the field of printing and dyeing, can solve the problems of poor physical and chemical indicators, difficulty in balancing gloss and hand feeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

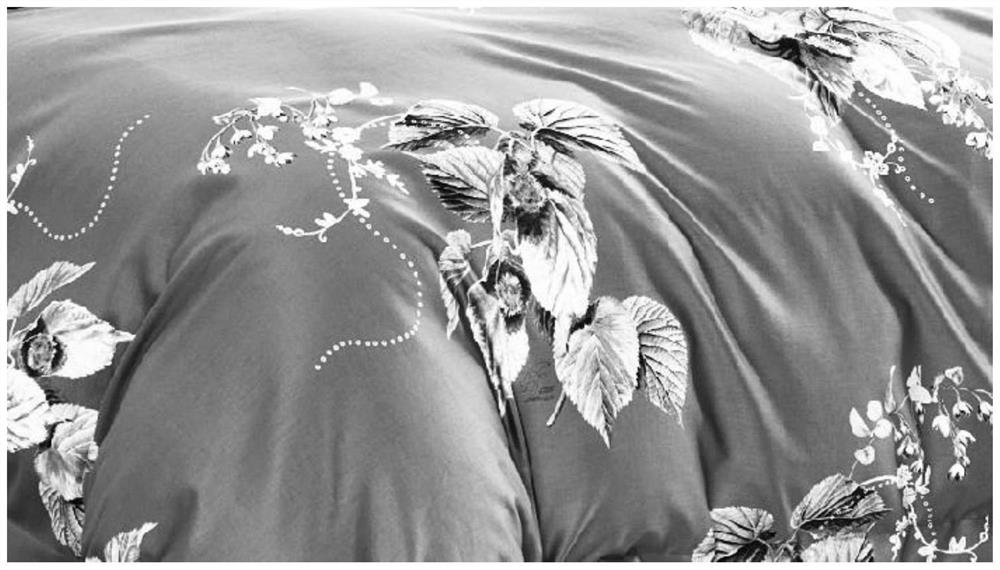

Image

Examples

Embodiment 1

[0073] A method for printing and dyeing pure cotton fabrics with silky luster, comprising the following steps:

[0074] Step 1, gray cloth raw materials:

[0075] The raw material of the gray cloth is pure cotton satin fabric, which is woven from Xinjiang long-staple combed cotton through the weaving method of five pieces of double flying; the raw material specification of the gray cloth is pure cotton combed satin 40*40133*90105 inches;

[0076] The physical indicators of gray cloth raw materials are:

[0077] (US, Europe) Color fastness to washing Discoloration / staining Original change 3; white 3 Color fastness to dry rubbing / wet rubbing Dry grinding level 3; wet grinding level 2~3 Anti-wrinkle appearance after washing Level 3 Breaking strength (warp / weft) 220N Pilling Level 3 Density Warp / Weft ±3% Gram weight 136±5g / m 2

[0078] Step 2, spread the cloth and seam:

[0079] The gray cloth is spread and stitched, and this ...

Embodiment 2

[0137] A method for printing and dyeing pure cotton fabrics with silky luster, comprising the following steps:

[0138] Step 1, gray cloth raw materials:

[0139] The raw material of the gray cloth is pure cotton satin fabric, which is woven from Xinjiang long-staple combed cotton through the weaving method of five pieces of double flying; the raw material specification of the gray cloth is pure cotton combed satin 40*40133*90105 inches;

[0140] The physical indicators of gray cloth raw materials are:

[0141] (US, Europe) Color fastness to washing Discoloration / staining Original change 3; white 3 Color fastness to dry rubbing / wet rubbing Dry grinding level 3; wet grinding level 2~3 Anti-wrinkle appearance after washing Level 3 Breaking strength (warp / weft) 220N Pilling Level 3 Density Warp / Weft ±3% Gram weight 136±5g / m 2

[0142] Step 2, spread the cloth and seam:

[0143] The gray cloth is spread and stitched, and this st...

Embodiment 3

[0203] A method for printing and dyeing pure cotton fabrics with silky luster, comprising the following steps:

[0204] Step 1, gray cloth raw materials:

[0205] The raw material of the gray cloth is pure cotton satin fabric, which is woven from Xinjiang long-staple combed cotton through the weaving method of five pieces of double flying; the raw material specification of the gray cloth is pure cotton combed satin 40*40133*90105 inches;

[0206] The physical indicators of gray cloth raw materials are:

[0207]

[0208]

[0209] Step 2, spread the cloth and seam:

[0210] The gray cloth is spread and stitched, and this step is a conventional method in the prior art;

[0211] Step 3, burning and rolling:

[0212] Burning means singeing and desizing, burning off the fluff on the surface of the gray cloth, and removing the slurry from the fabric fibers; the working fluid formula of burning and rolling: magnesium sulfate is 0.7g / L, chelating dispersant MEX is 4g / L, causti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com